Downhole throttling device based on special degradable alloy ball tapered plug adjustment

A throttling device and alloy ball technology, which is applied in wellbore/well valve device, wellbore/well components, earth-moving drilling, etc., can solve the complex process, time-consuming and laborious, and inability to adjust the throttling area of the gas nozzle. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

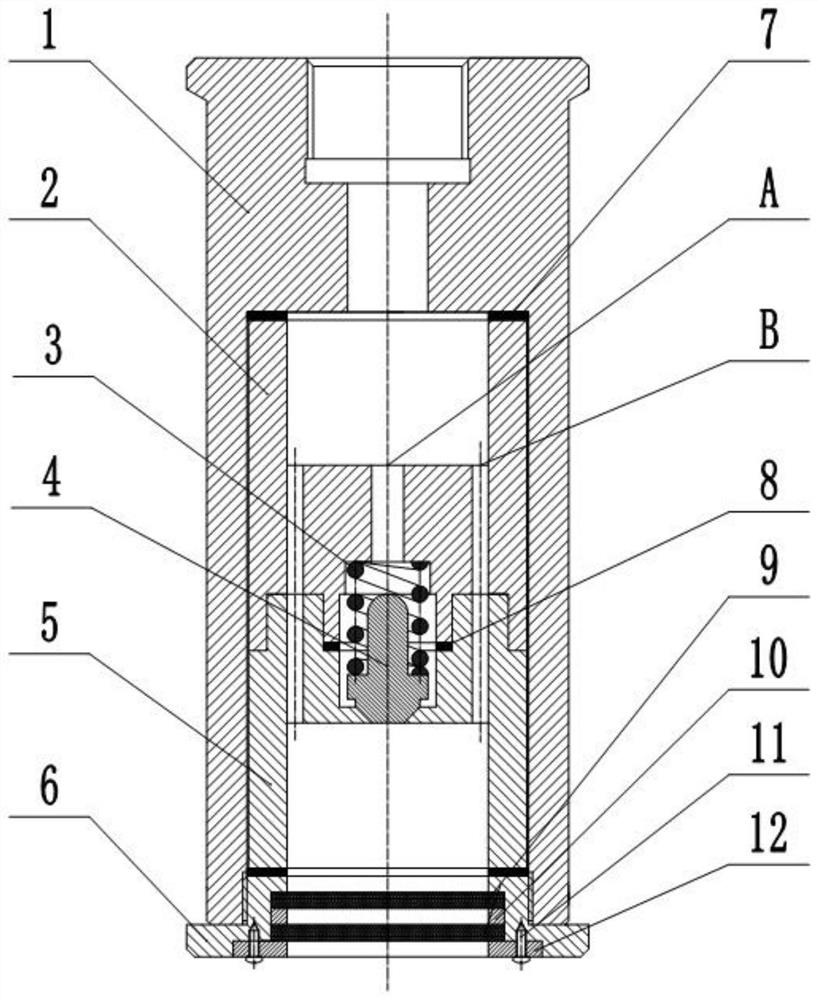

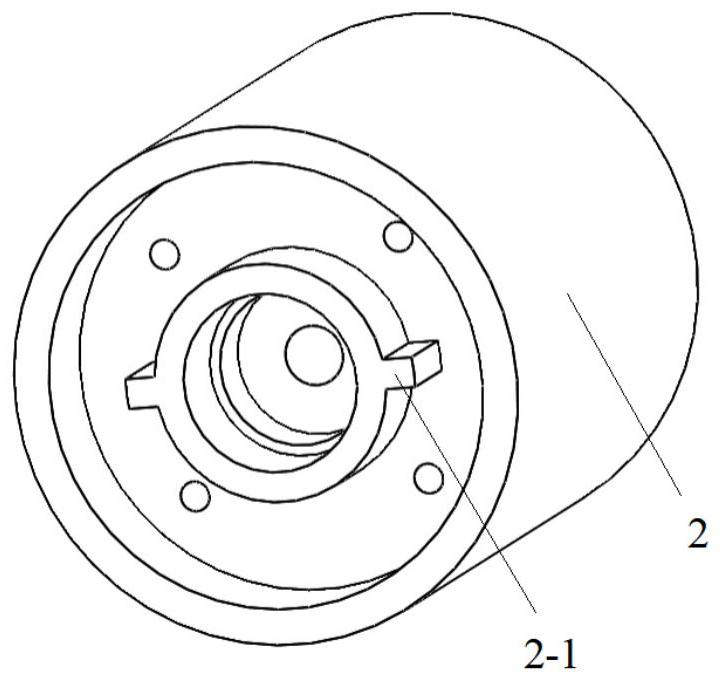

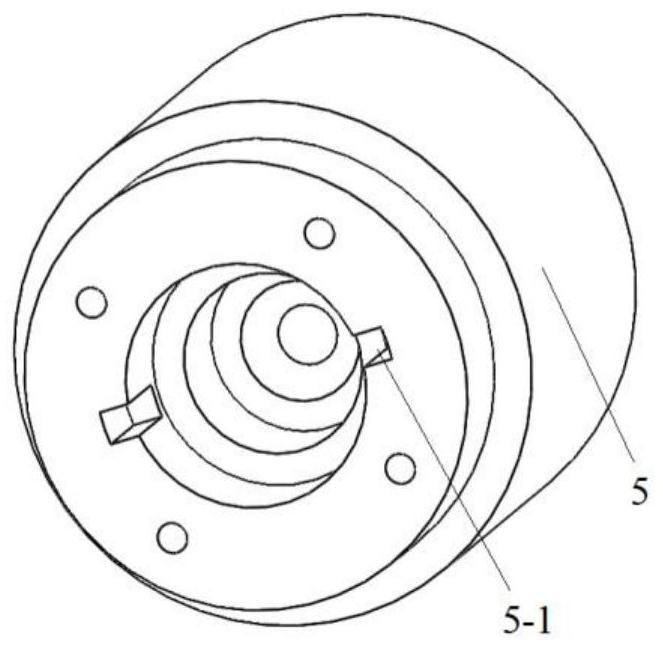

[0017] refer to figure 1 , a downhole throttling device adjusted based on a special degradable alloy ball-taper plug, which is threadedly connected to the central axis of the throttle, including an upper seat 2 and a lower seat 5 with a clearance fit, and a cavity between the upper seat 2 and the lower seat 5 The chamber is equipped with a spring 3, a ball cone plug 4 and a small sealing ring 8, the spring 3 is installed in the groove of the upper seat 2, the upper end of the ball cone plug 4 goes deep into the interior of the spring 8, and the lower end of the ball cone plug 4 matches the taper hole of the lower seat 5 , a small sealing ring 8 is installed at the joint between the upper seat 2 and the lower seat 5; the upper seat 2 and the lower seat 5 are assembled together in the fixed cover 1, and are sealed by the upper and lower large sealing rings 7, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com