Polished shaft quenching machine tool for injection molding machine

A technology for quenching machine tools and injection molding machines, which is applied to quenching devices, furnace types, furnaces, etc., and can solve problems such as waste of loading and unloading actions of vertical machine tools, increased costs, and insufficient long-axis travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

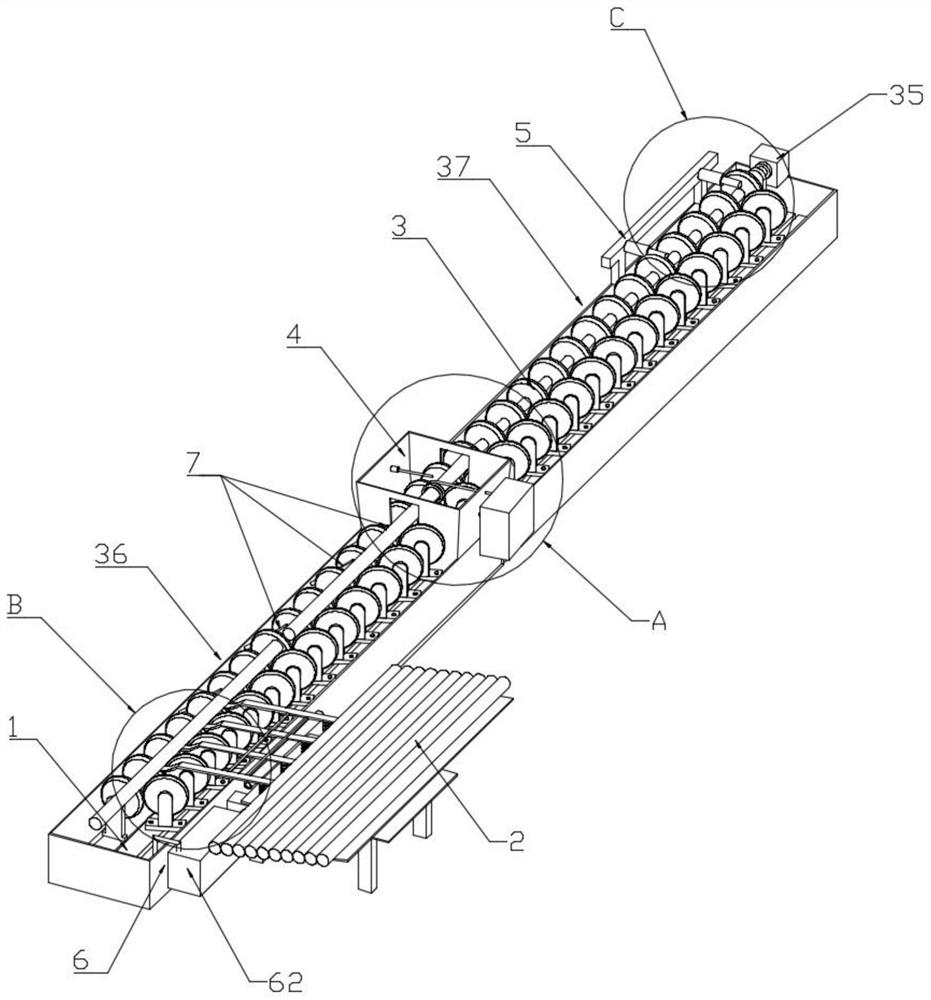

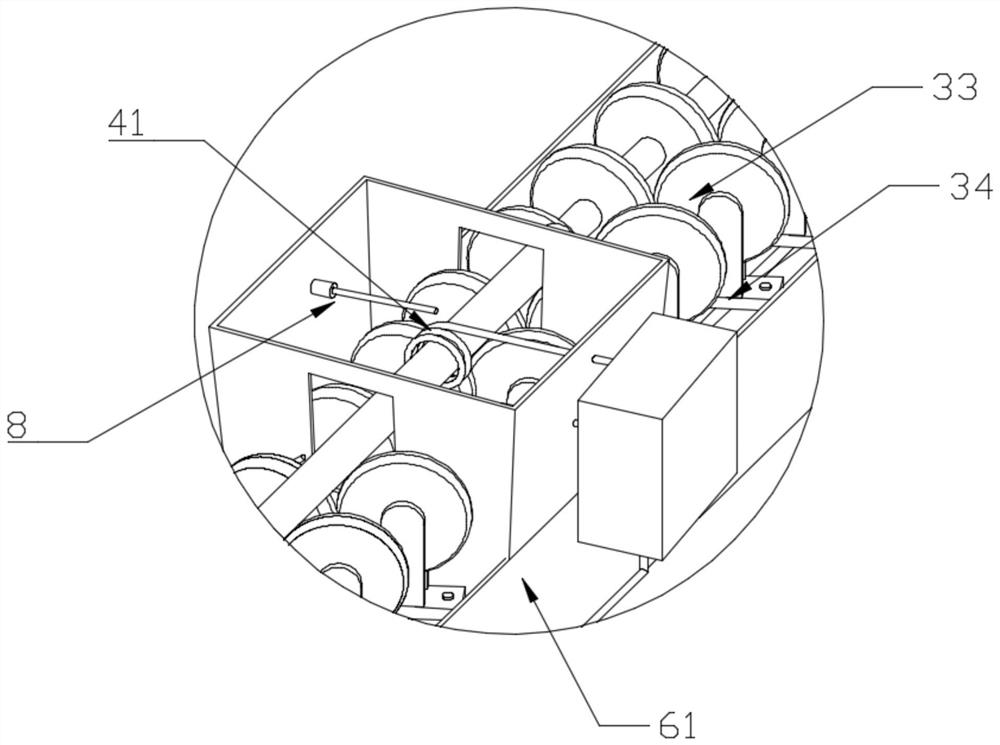

[0031] Such as Figure 1 to Figure 7 As shown, an optical axis quenching machine tool for an injection molding machine includes a support mechanism 1, a feeding mechanism 2, a conveying mechanism 3, a quenching mechanism 4, a blanking mechanism 5 and a local quenching adjustment mechanism; the conveying mechanism 3 is arranged on The upper end of the supporting mechanism 1, the feeding mechanism 3 includes a feeding mechanism 36 and a discharging mechanism 37 arranged in a straight line, the feeding mechanism 2 and the unloading mechanism 5 are respectively arranged at two ends of the feeding mechanism 3, and the quenching mechanism 4 It is arranged between the feeding mechanism 36 and the discharging mechanism 37;

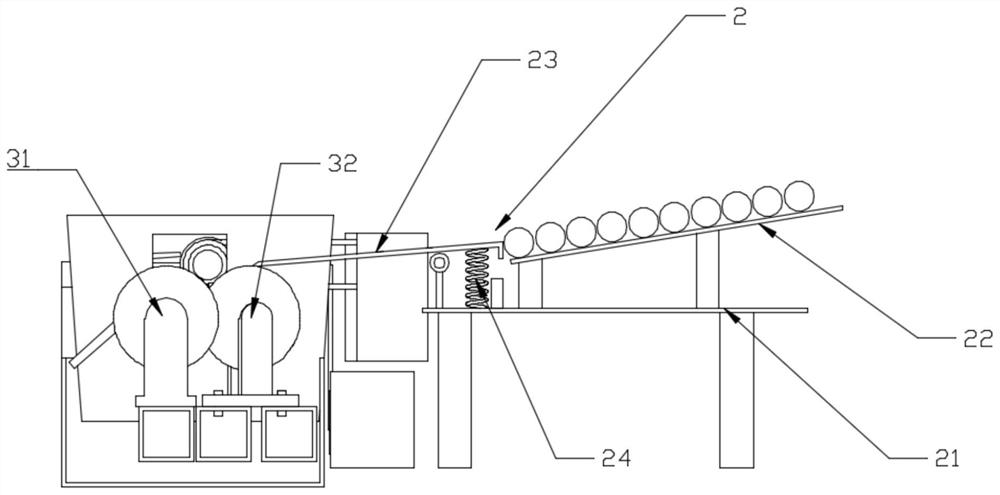

[0032] Feeding mechanism 36 and discharging mechanism 37 all comprise driving wheel set 31 and passive wheel set 32, and driving wheel set 31 and passive wheel set 32 are arranged in the same direction, and driving wheel set 31 is a straight wheel, and driven wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com