Sewage online concentrated fracturing fluid and preparation method thereof

A fracturing fluid and sewage technology, applied in the field of fracturing fluid, can solve problems such as poor control of dosing accuracy, waste of water resources, cold damage to oil wells in low-temperature oil layers, etc., to solve the problem of low-temperature gel breaking and high-temperature gel breaking, saving The effect of processing costs and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

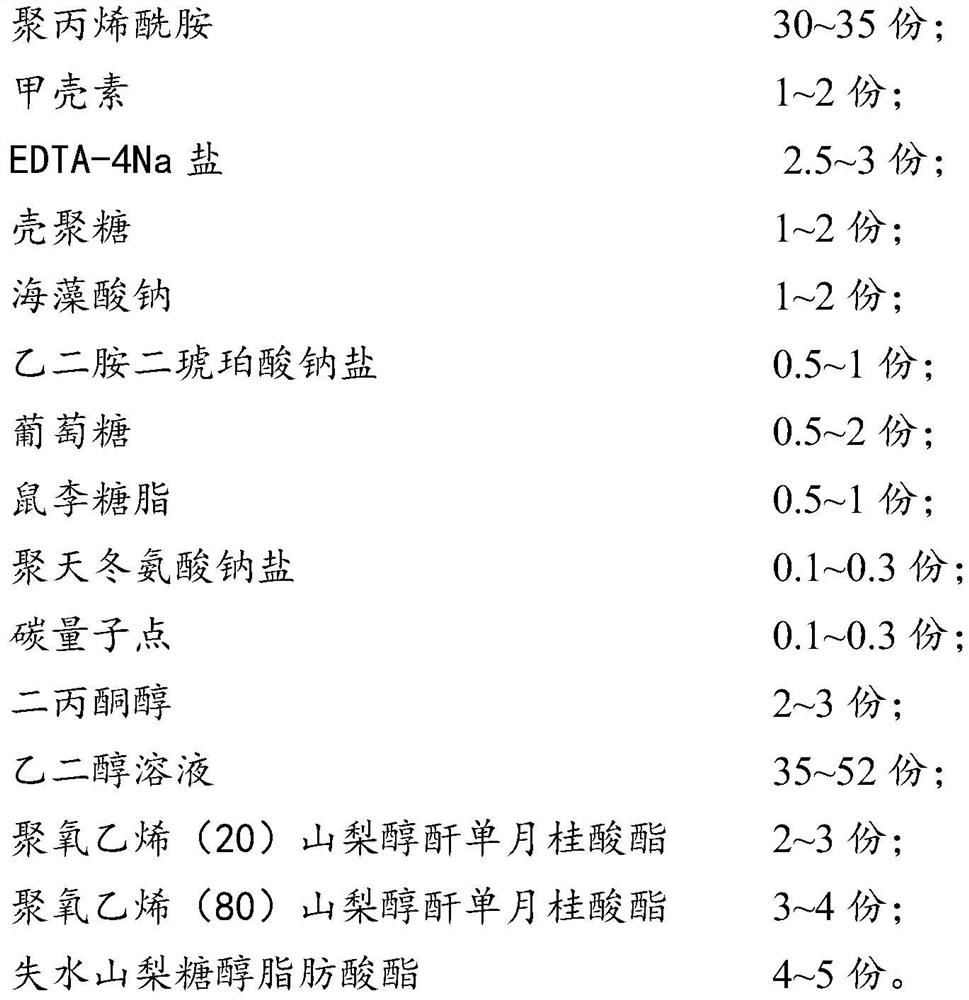

[0030] This embodiment provides an online concentrated fracturing fluid for sewage, which includes the following components in parts by weight:

[0031]

[0032]

[0033] Among them, the molecular weight of the polyacrylamide is 5 million to 18 million, and the particle size is 200 to 500 mesh; the concentration of the ethylene glycol solution is greater than 50%.

[0034] The method for preparing the sewage online concentrated fracturing fluid comprises the following steps:

[0035] Disperse 30 parts of polyacrylamide and 1 part of chitin in 51.8 parts of ethylene glycol solution, and emulsify with high shear for 30 minutes to obtain a mixed solution;

[0036] Add 2.5 parts of EDTA-4Na salt and 1 part of chitosan to the above mixture, and emulsify with high shear for 30 minutes;

[0037] Continue to add 1 part of sodium alginate to the above mixture, and emulsify with high shear for 10 minutes;

[0038] Continue to add 0.5 parts of ethylenediamine disuccinic acid sodi...

Embodiment 2

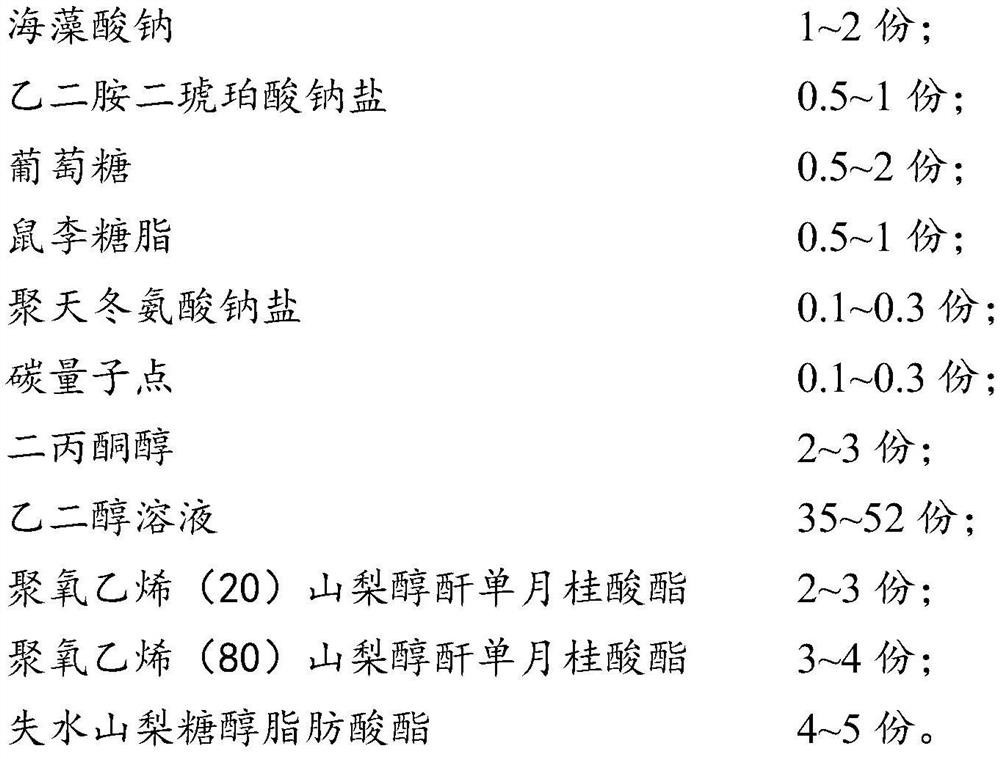

[0044] This embodiment provides an online concentrated fracturing fluid for sewage, which includes the following components in parts by weight:

[0045]

[0046]

[0047] The method for preparing the sewage online concentrated fracturing fluid comprises the following steps:

[0048] Disperse 33 parts of polyacrylamide and 1.5 parts of chitin in 43.2 parts of ethylene glycol solution, and emulsify with high shear for 30 minutes to obtain a mixed solution;

[0049] Add 2.8 parts of EDTA-4Na salt and 1.5 parts of chitosan to the above mixture, and emulsify with high shear for 30 minutes;

[0050] Continue to add 1.5 parts of sodium alginate to the above mixture, and emulsify with high shear for 10 minutes;

[0051] Continue to add 0.8 parts of ethylenediamine disuccinic acid sodium salt to the above mixture, and emulsify with high shear for 20 minutes;

[0052] Continue to add 1.5 parts of glucose and 0.8 parts of rhamnolipid to the above mixture, and emulsify with high s...

Embodiment 3

[0057] This embodiment provides an online concentrated fracturing fluid for sewage, which includes the following components in parts by weight:

[0058]

[0059]

[0060] The method for preparing the sewage online concentrated fracturing fluid comprises the following steps:

[0061] Disperse 35 parts of polyacrylamide and 2 parts of chitin in 36.4 parts of ethylene glycol solution, and emulsify with high shear for 30 minutes to obtain a mixed solution;

[0062] Add 3 parts of EDTA-4Na salt and 2 parts of chitosan to the above mixture, and emulsify with high shear for 30 minutes;

[0063] Continue to add 2 parts of sodium alginate to the above mixture, and emulsify with high shear for 10 minutes;

[0064] Continue to add 1 part of ethylenediamine disuccinic acid sodium salt to the above mixture, and emulsify with high shear for 20 minutes;

[0065] Continue to add 2 parts of glucose and 1 part of rhamnolipid to the above mixture, and emulsify with high shear for 30 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com