Inflatable flat winding chuck

An inflatable collet technology, applied in the field of inflatable flat rewinding collets, can solve the problems of large axial size, high cost, and large space occupation of the rewinding collet, and achieve stable airway control Convenience, guaranteed stability, stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

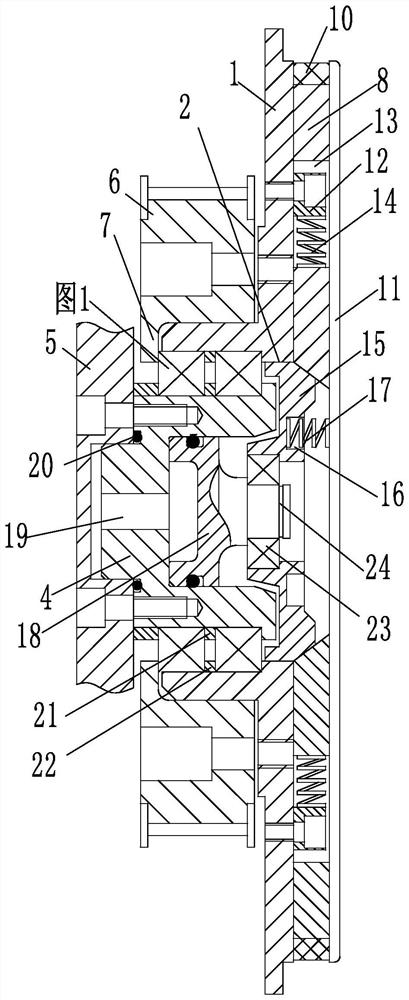

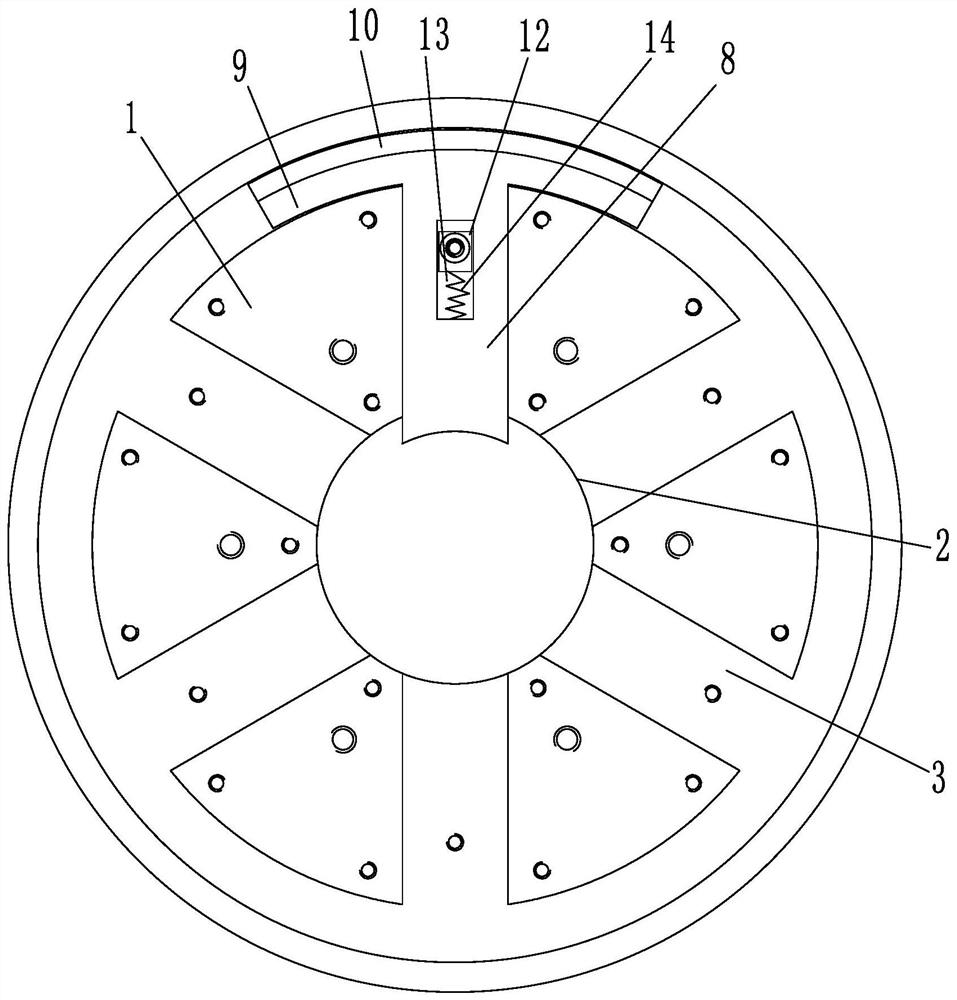

[0024] figure 1 and figure 2Among them, an inflatable flat rewinding collet is characterized in that it includes a collet body 1, the collet body 1 is a stepped shaft structure composed of two coaxial cylinders, and the two parts of the collet body 1 are arranged according to the diameter. The section cylinder is divided into a large shaft and a small shaft. One side of the chuck main body 1 is rotated to be provided with an end shaft 4 , and the inside of the chuck main body 1 is provided with a cylindrical hole for installing the end shaft 4 . The end shaft 4 is threadedly connected with a winding driving arm 5, the end shaft 4 is connected with the chuck main body 1 through a pair of bearings, and the cylindrical hole and the bearing are interference fit. A fixed-distance inner ring 21 and a fixed-distance outer ring 22 are arranged between the paired bearings. The fixed-distance inner ring 21 is interference-fitted on the end shaft 4, and the outer side of the fixed-dis...

Embodiment 2

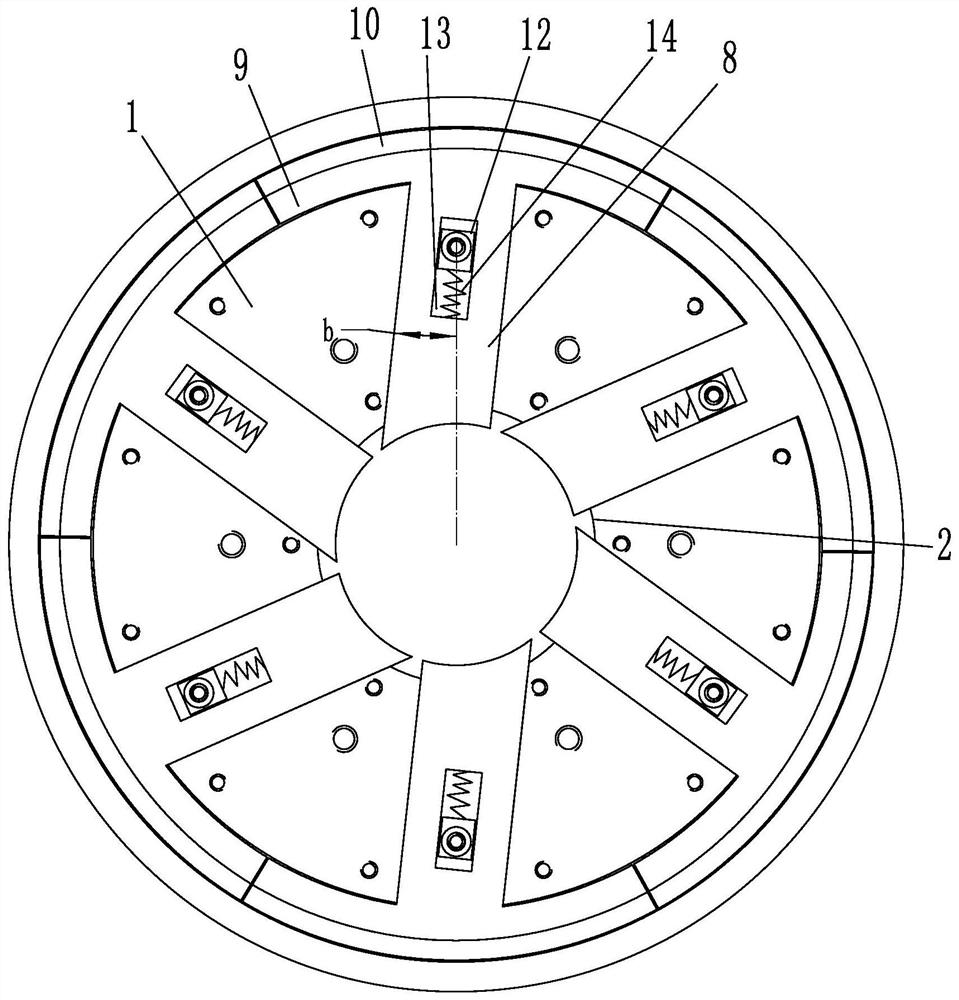

[0026] An inflatable flat rewind chuck, such as image 3 As shown, the difference between Embodiment 2 and Embodiment 1 is that the straight line where the limit block 12 and the chute 13 are located is set radially obliquely to the collet body 1 where the limit block 12 is located, and the position where the limit block 12 and the chute 13 are located The included angle b between the straight line and the radial inclination of the collet body 1 where the limit block 12 is located can be selected within the range of 5 to 8 degrees, and the embodiment adopts 6.15 degrees. Sliding groove 3 and chute 13 are parallel. The collet expansion block 8 is arranged obliquely with the sliding groove 3, and a certain inclination angle is formed between the collet expansion block 8 and the chuck main body 1. The pressure of the block 8 is partly borne by the chuck main body 1 through the inclination angle, which reduces the matching pressure between the inner end of the chuck expansion blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com