Cement tanker discharging pipe capable of automatically adjusting length

A cement tanker and automatic adjustment technology, which is used in oil tankers, motor vehicles, and vehicles for freight transportation, etc., can solve the problem of requiring more effort and time for leveling, cement unloading that cannot be filled evenly and evenly, and spare unloading. Problems such as complicated pipe installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

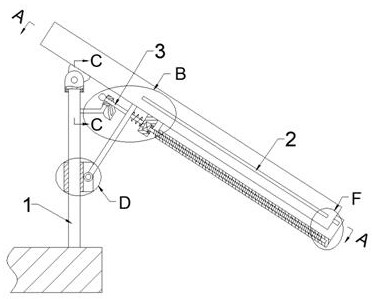

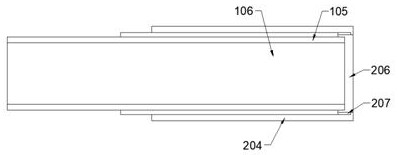

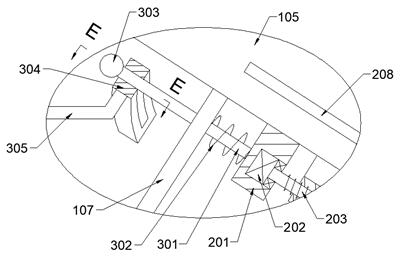

[0024] Such as Figure 1-8 As shown, a cement tank truck discharge pipe that can automatically adjust the length includes a rotating rod 101 fixed at the tail of the cement tank truck, and the rotating rod 101 is provided with a rotating mechanism 1 for conveying cement when unloading. Mechanism 1 includes a rotating conveying pipe 105 rotatably provided on the rotating rod 101, and a telescopic conveying pipe 204 is slidably provided on the rotating conveying pipe 105, and a telescopic conveying pipe 204 is provided for controlling the The telescoping mechanism 2 that the telescopic conveying pipe 204 slides up and down, is fixedly connected with the carriage connecting rod 305 on the described rotating rod 101, and the described carriage connecting rod 305 is provided with to be used for adjusting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com