Street lamp pole transportation protective film winding device for urban construction

A technology for urban construction and street light poles, which is applied in transportation and packaging, packaging/bundling items, packaging, etc., and can solve the problems of long street light poles, high cost, and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

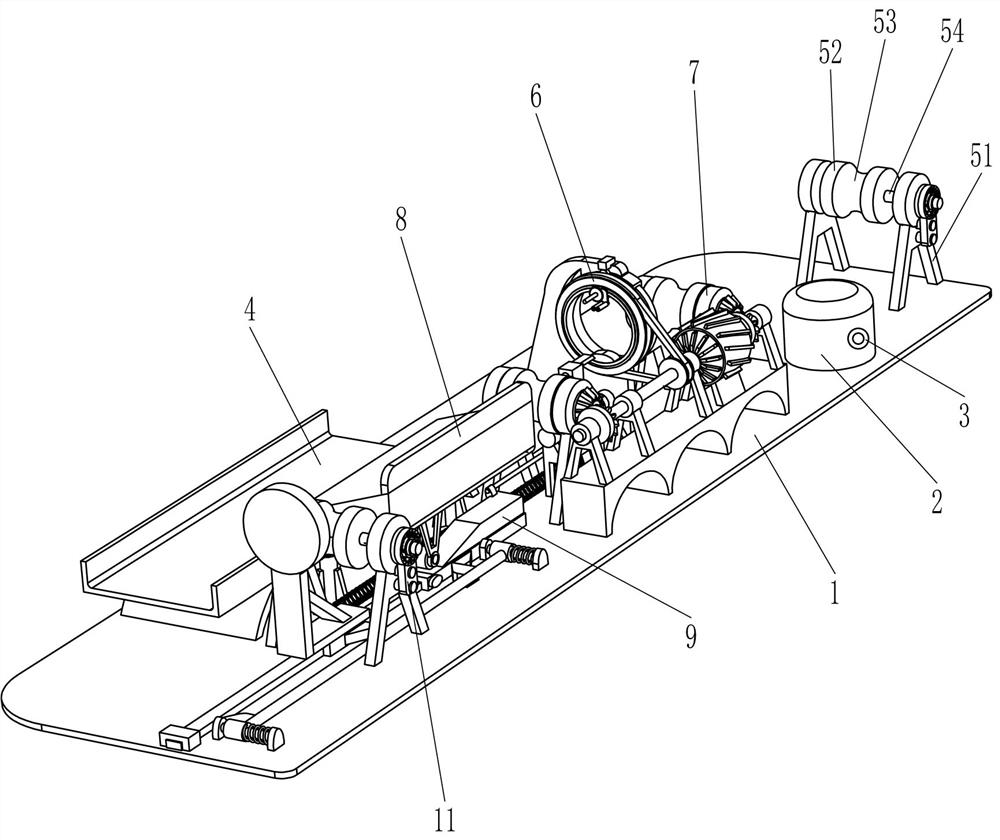

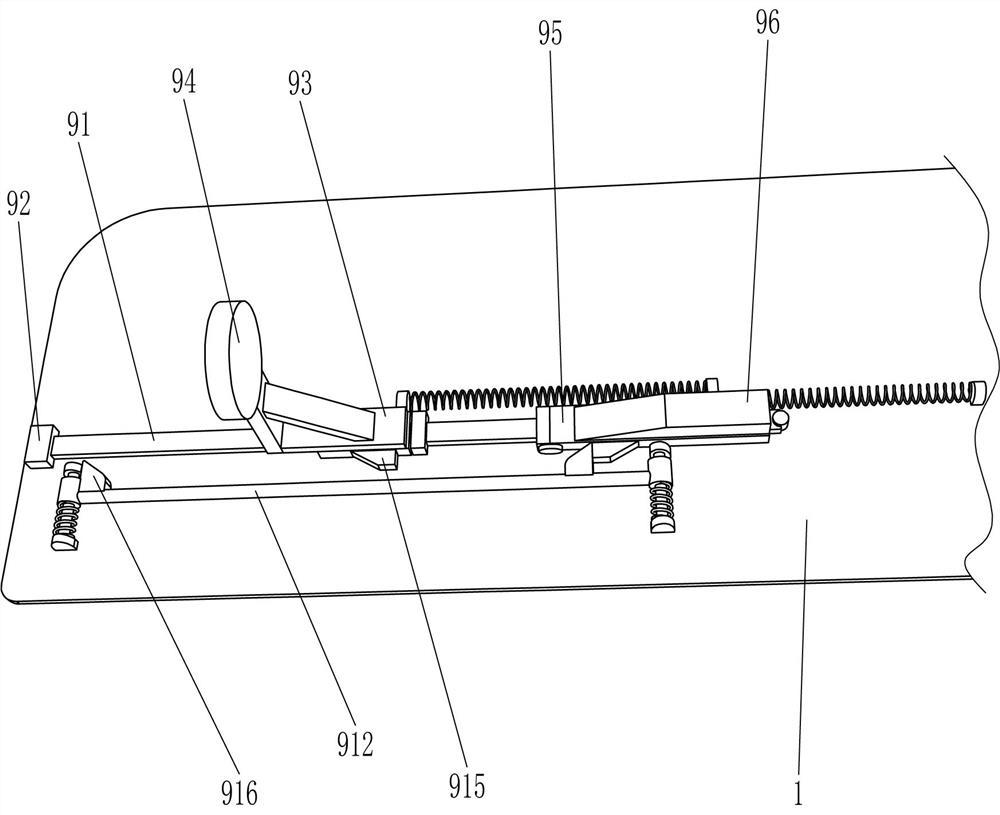

[0035] A kind of protective film winding device for transporting protective film on street light poles for urban construction, such as Figure 1-6As shown, it includes an operation table 1, a collection frame 4, a first support 51, a roller 52, a rotating rod 54, a feeding mechanism 6, a moving mechanism 7, a material receiving mechanism 8 and a jacking mechanism 9, and the left rear side of the top of the operation table 1 A collection frame 4 is provided, and two first brackets 51 are connected to the left and right sides of the top of the console 1, and a rotating rod 54 is installed between the two first brackets 51 on the left side, and the two first brackets on the right side The rotating type between 51 is also equipped with a rotating rod 54, and the middle part of the two rotating rods 54 is equipped with a drum 52, and the outer side of the drum 52 is provided with a placement groove 53, and a feeding mechanism 6 and a moving mechanism 7 are installed in the middle of...

Embodiment 2

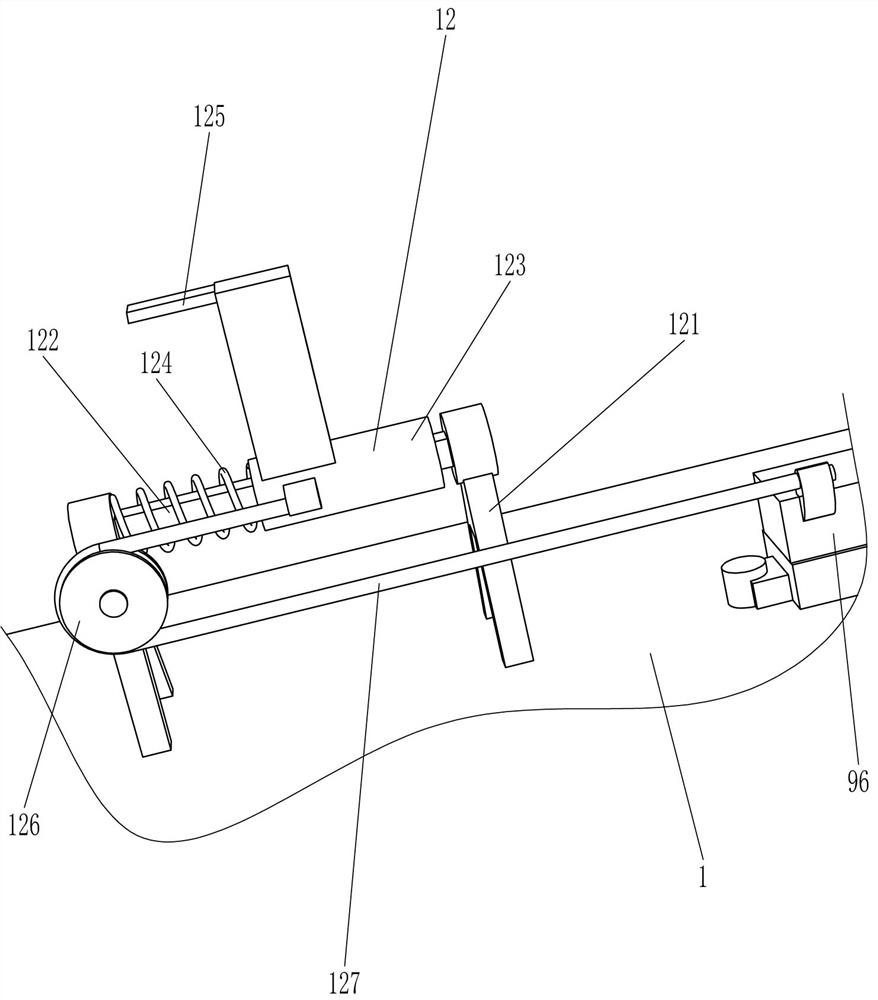

[0046] On the basis of Example 1, such as image 3 , Image 6 , Figure 7 with Figure 8 As shown, a non-return mechanism 11 is also included. The non-return mechanism 11 includes a locking frame 111, an inner ring gear 112, a bayonet 113 and a shrapnel 114, and the front sides of the two first brackets 51 on the front side are connected to the locking frame 111. , the tops of the two locking frames 111 are connected with an inner ring gear 112, and the outer sides of the two rotating rods 54 are evenly spaced rotationally connected with four locking teeth 113, the locking teeth 113 mesh with the inner ring gear 112, and the locking teeth 113 and the rotation Elastic pieces 114 are connected between the rods 54 .

[0047] When the street light pole moves to the left, the friction force drives the roller 52 to rotate counterclockwise, and the roller 52 drives the rotating rod 54 to rotate counterclockwise, and the rotating rod 54 drives the latch 113 to rotate counterclockwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com