A smart packaging wrapping mechanism for carton production equipment in an intelligent workshop

A technology for production equipment and carton, applied in the field of carton surface processing mechanism, can solve the problems of low production efficiency and consume a lot of manpower, and achieve the effect of improving production efficiency and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is attached Figure 1-10 The application is described in further detail.

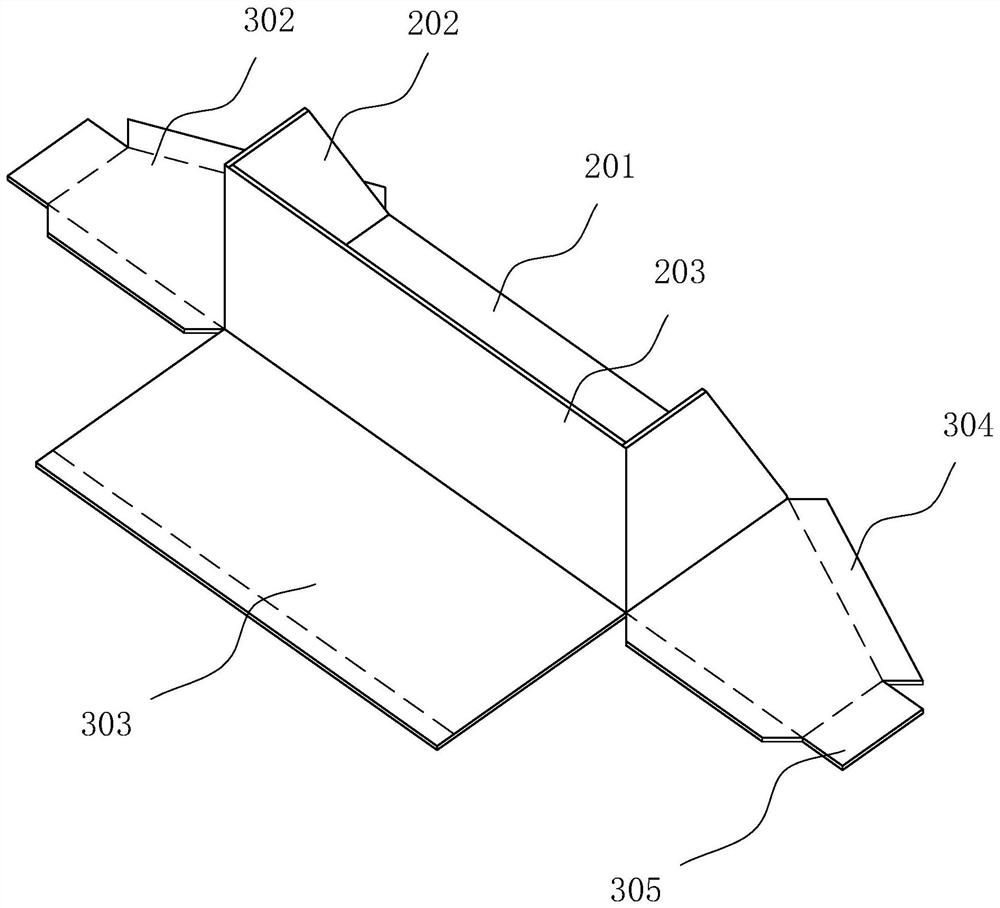

[0047] refer to figure 1 , a carton, including a rectangular bottom plate 201 and a rectangular side plate 203, the side plate 203 is vertically arranged at one end of the width direction of the bottom plate 201, and the two ends of the length direction of the bottom plate 201 are provided with connecting plates for connecting the bottom plate 201 and the side plate 203 202 , the connecting plate 202 is in the shape of a right-angled trapezoid with a narrow top and a wide bottom, and the side plates 203 and the connecting plate 202 are fixed by glue.

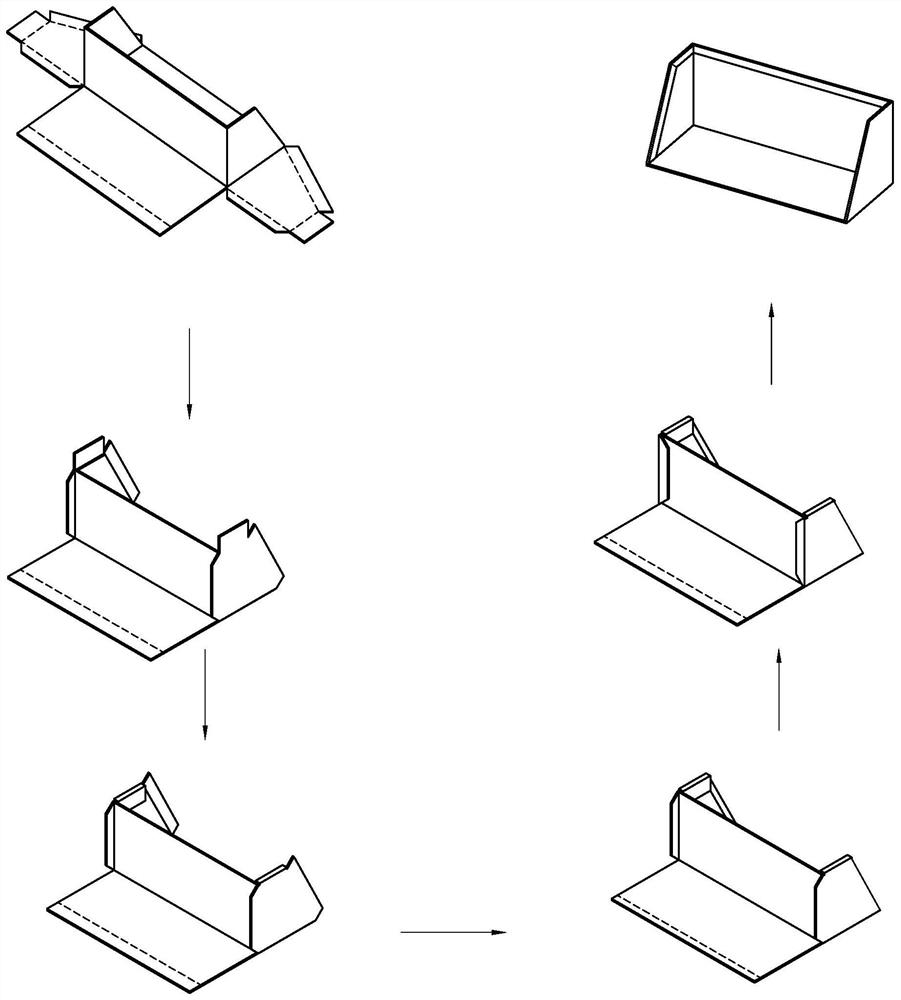

[0048] refer to figure 2 , a wrapping paper, comprising a rectangular bottom sheet 301 and a rectangular side sheet 303, and the edge wrapping strip extends along the length direction of the side sheet 303. Both ends of the bottom sheet 301 in the longitudinal direction are provided with end sheets 302, both sides of the end sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com