Efficient diamond wire saw for cutting brittle material, and application thereof

A technology of diamond wire saws and brittle materials, applied in metal processing equipment, stone processing equipment, fine working devices, etc., can solve problems such as insufficient carrying capacity, shortened unit cutting time, soft metal coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

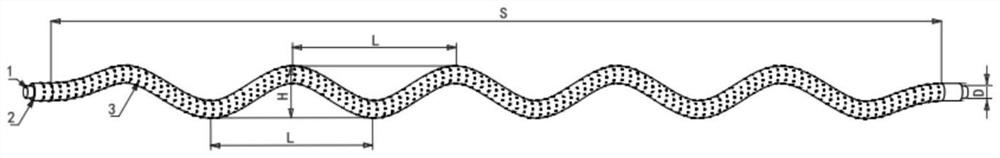

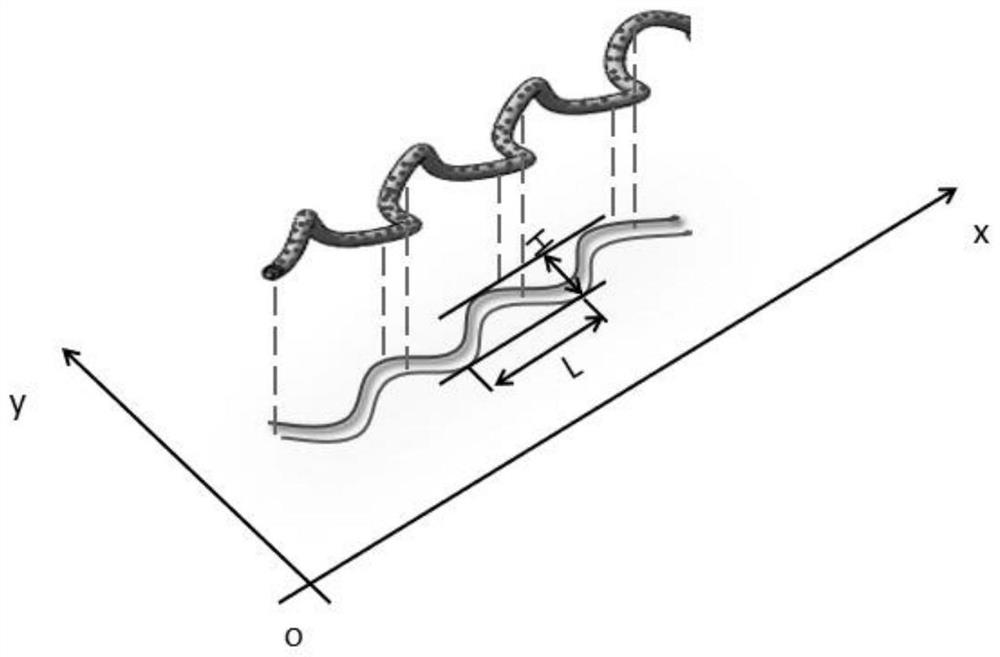

Image

Examples

Embodiment 12

[0061] Cutting experiments were performed on the diamond wire saws prepared in Examples 1 to 11 in the above table.

[0062] The cutting object is a silicon rod, the silicon rod specification is G1, the length of the silicon rod is 800mm, and the thickness of the sheet is 175um. The tension of the wire is 60% of the breaking force of the diamond wire saw. s, acceleration 5 to 6m / s.

[0063] Then perform statistics or inspections on the primary yield rate, A rate, line marks and TTV after cutting.

[0064] After cutting the silicon rod, the experimental results are as follows:

[0065] The experimental comparative result of table 2 embodiment 1-11

[0066]

[0067]

[0068] Note:

[0069] 1) The line mark refers to the height difference between the surface protrusions and depressions along the line direction, generally greater than 13um is a line mark sheet. The line mark (%) in the above table refers to the number of line mark pieces larger than 13um / ratio of all sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com