Prestressed concrete slab mold and manufacturing method thereof

A technology of concrete slabs and manufacturing methods, which is applied in the field of building accessories manufacturing, and can solve the problems of no formwork, time-consuming and labor-consuming, and formwork that cannot be reused.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

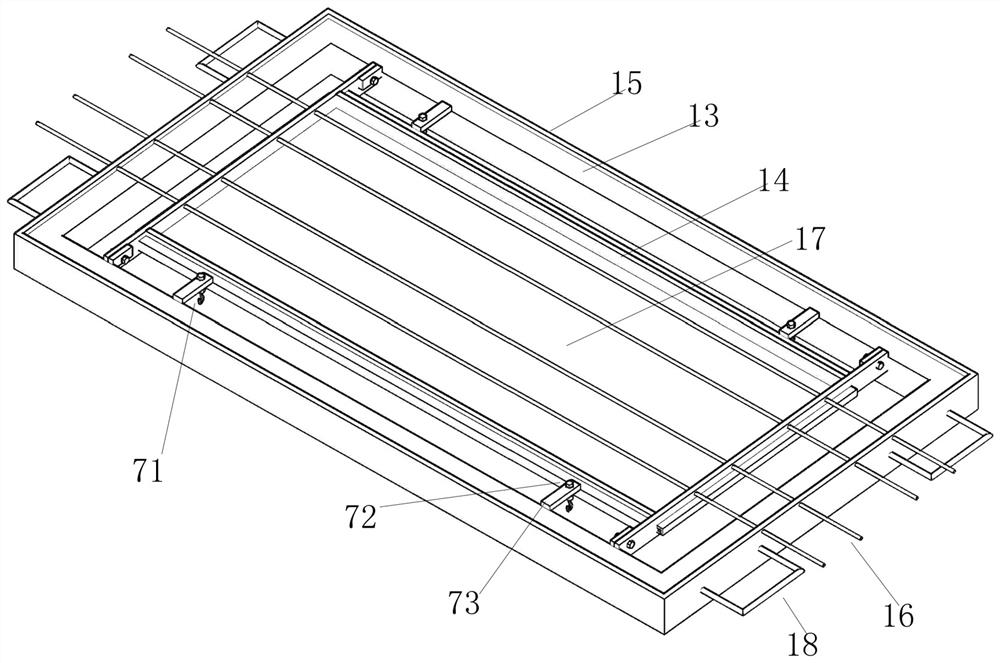

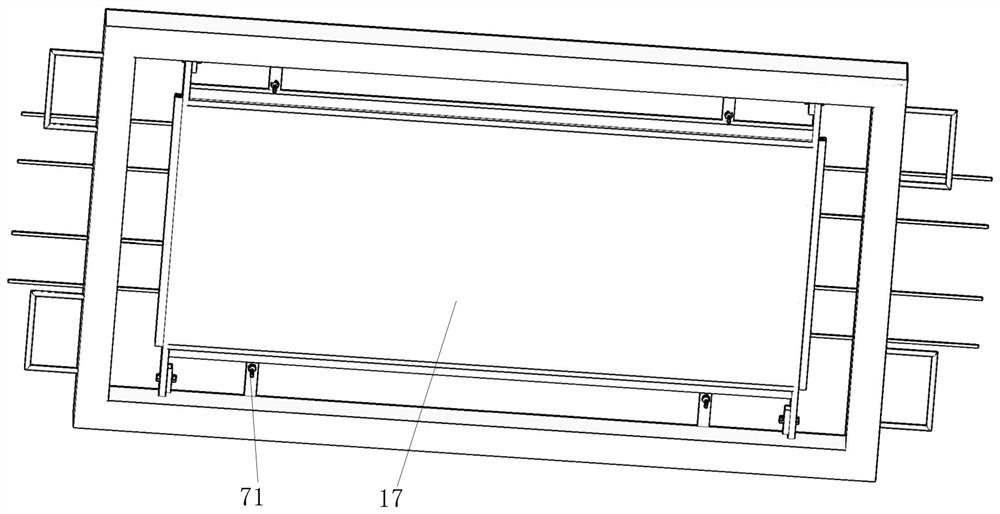

[0029] The preferred solution is as Figure 1 to Figure 11 As shown, a prestressed concrete slab mold includes an outer frame 13 and an inner frame 14. The outer edge of the outer frame 13 extends upwards to form an extension frame 15. The extension frame 15 is provided with a plurality of through holes, and the through holes are set through There are prestressed steel bars 16; the inner frame 14 is detachably connected with the outer frame 13, and the inner frame 14 is movably provided with a bottom plate 17, and the height of the bottom plate 17 is adjusted by a height adjustment device, and the height adjustment device is connected with the outer frame 13, and the bottom plate 17 The cover structure is formed with the inner frame 14; the inner frame 14 is provided with a through hole, and the prestressed steel bar 16 passes through the through hole on the inner frame 14.

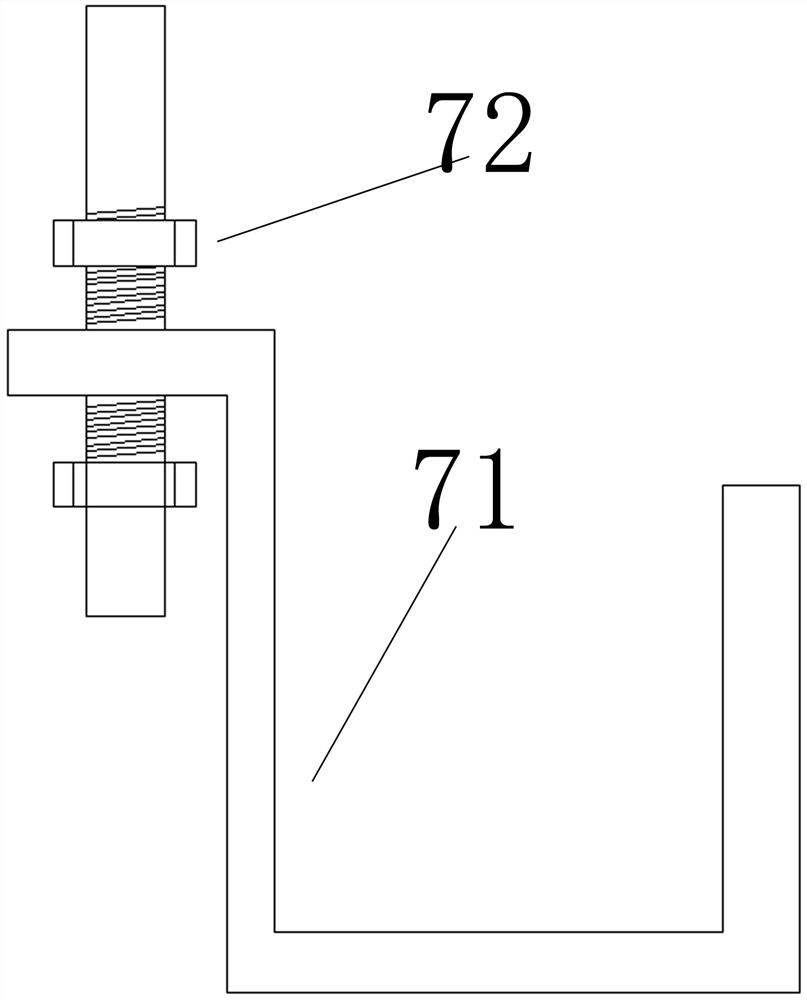

[0030] Further, the height adjustment device includes a hook body 71, the hook body 71 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com