Implosion detection device for catalytic debinding furnace

A detection device and catalytic degreasing technology, which is applied in the direction of furnace monitoring devices, furnaces, furnace components, etc., can solve the problems of lack of, recording function technology, no function technology, etc., and achieve the effect of simple structure, convenient use, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

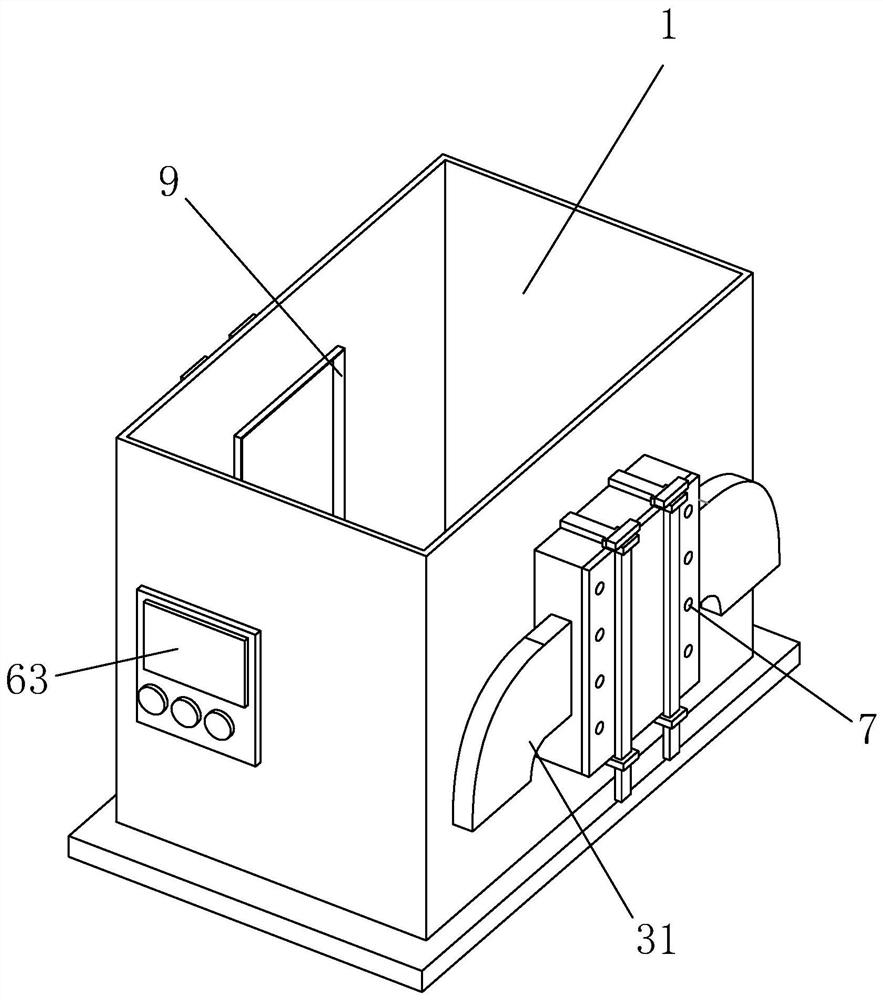

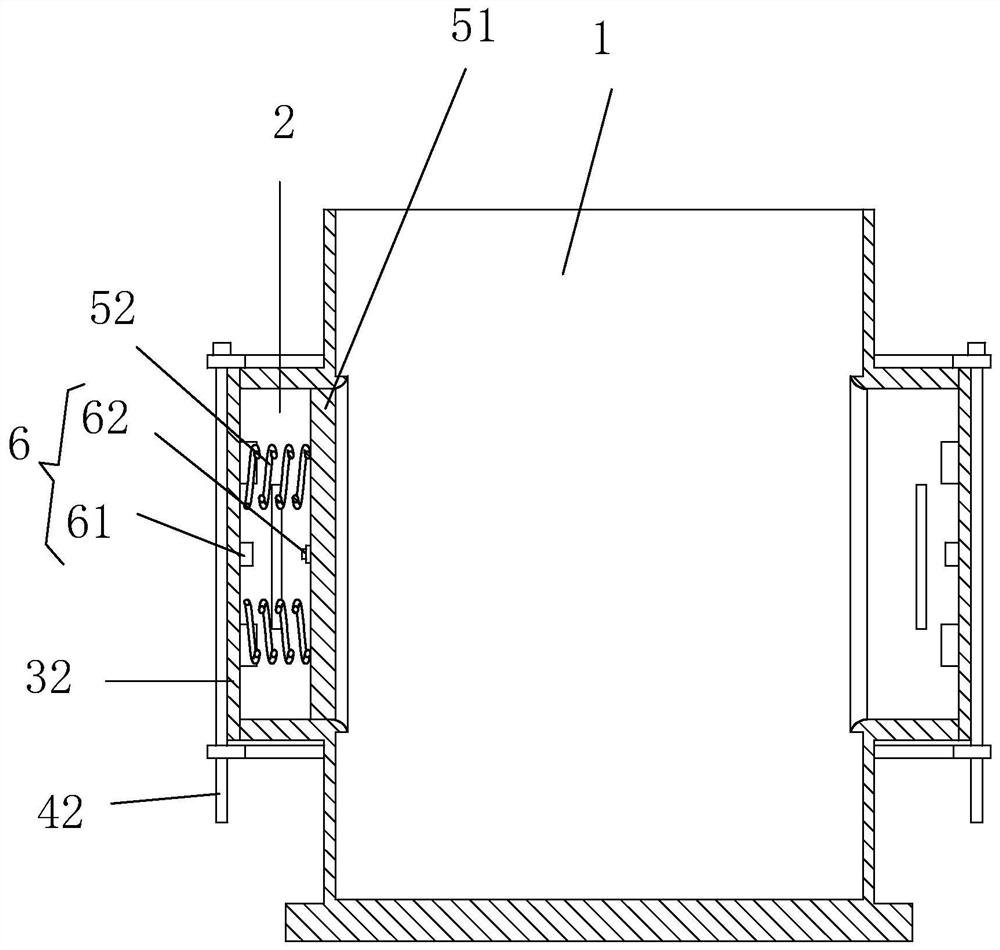

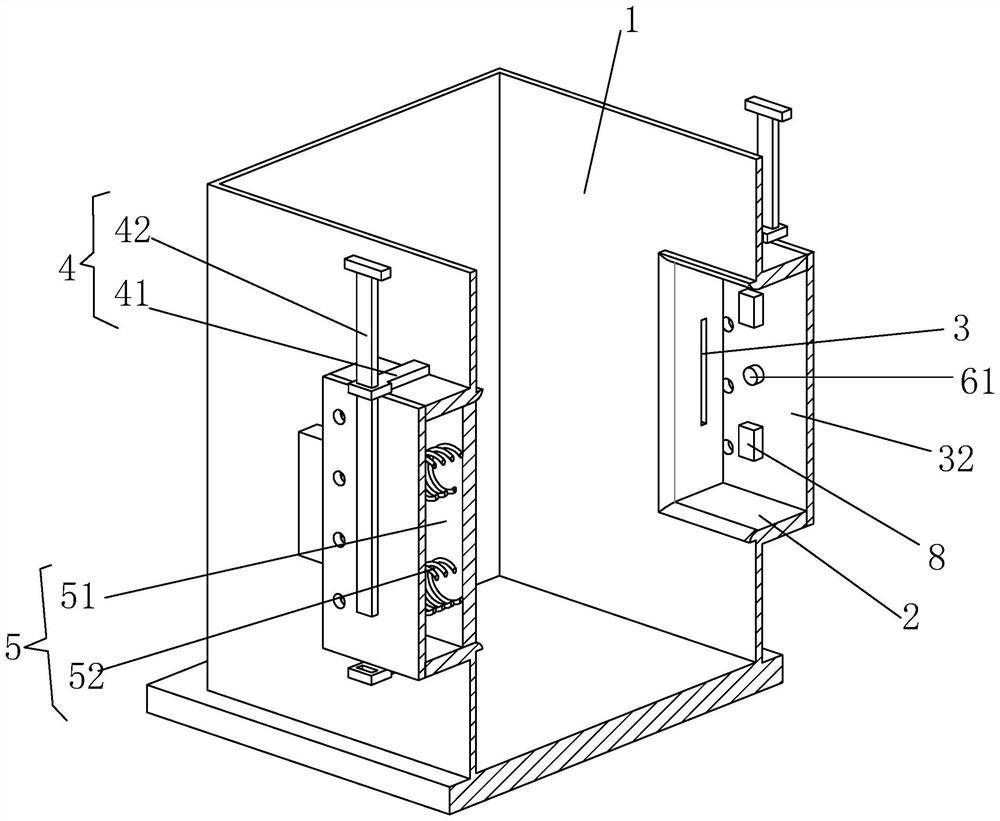

[0021] Such as Figures 1 to 3 Shown a kind of catalytic degreasing furnace implosion detection device, comprises body of heater 1, is provided with cavity 2 in described body of heater 1 both sides, is provided with vent hole 3 in both sides in described cavity 2, in the One side of the air release hole 3 is provided with an air release pipe 31, and one side of the cavity 2 is provided with a back plate 32, and the cavity 2 is provided with a locking structure 4 that fixes the back plate 32. 2 is provided with a buffer structure 5, and a detection device 6 is provided between the back plate 32 and the buffer structure 5. During use, when an implosion occurs, the gas is buffered by the buffer structure in the cavity, and the buffer structure is in the cavity Move in the body until the gas can be discharged from the air release hole. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com