An energy-saving and environment-friendly plastic chemical production equipment

A technology for chemical production, energy saving and environmental protection, applied in the chemical industry, sustainable manufacturing/processing, chemical/physical/physical chemical fixed reactors, etc., can solve the problem of low quality plastic additives, no graded processing, and low production efficiency and other problems, to achieve the effect of avoiding interruption of plastic processing, avoiding incomplete plastic processing, and facilitating cleaning or replacement

Active Publication Date: 2022-06-03

无锡享源信息科技有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The existing plastic chemical production equipment usually does not have the function of graded processing, which will lead to low quality and uneven mixing of the produced plastic additives

Not only that, the general plastic chemical production equipment also has many problems such as low production efficiency and complex structure.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

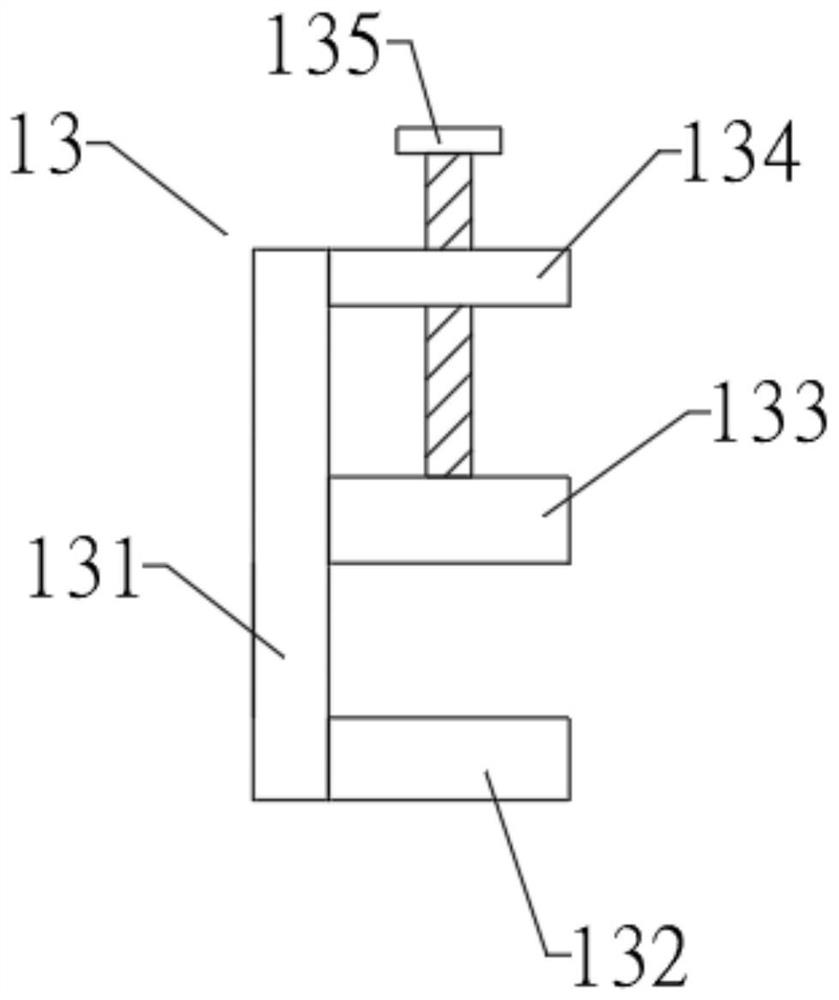

[0034] The clamping mechanism 13 consists of a fixed frame 131, a first fixed block 132, a movable block 133, a second fixed block 134 and a bolt 135

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

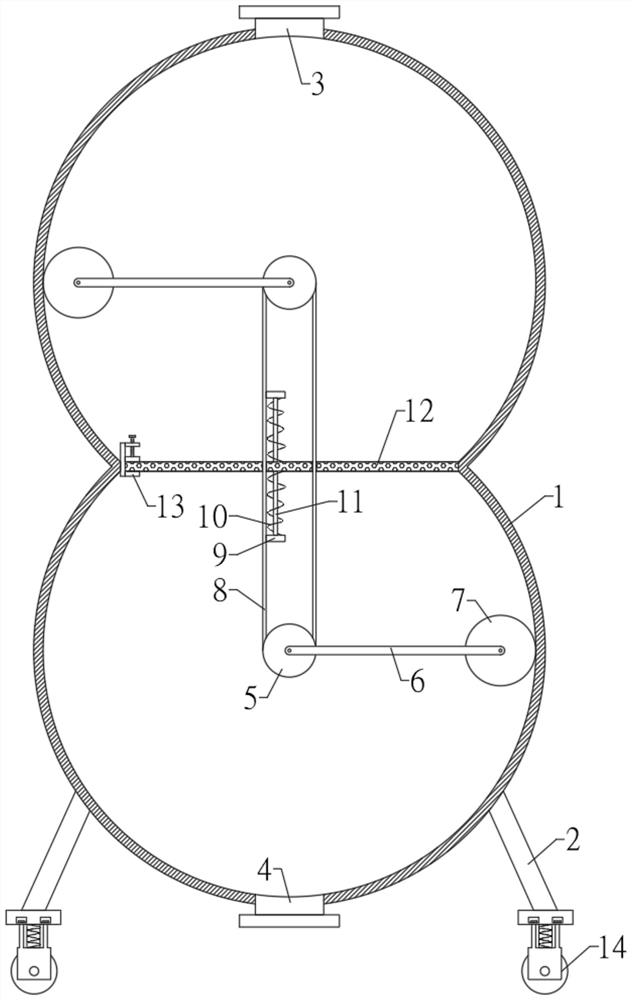

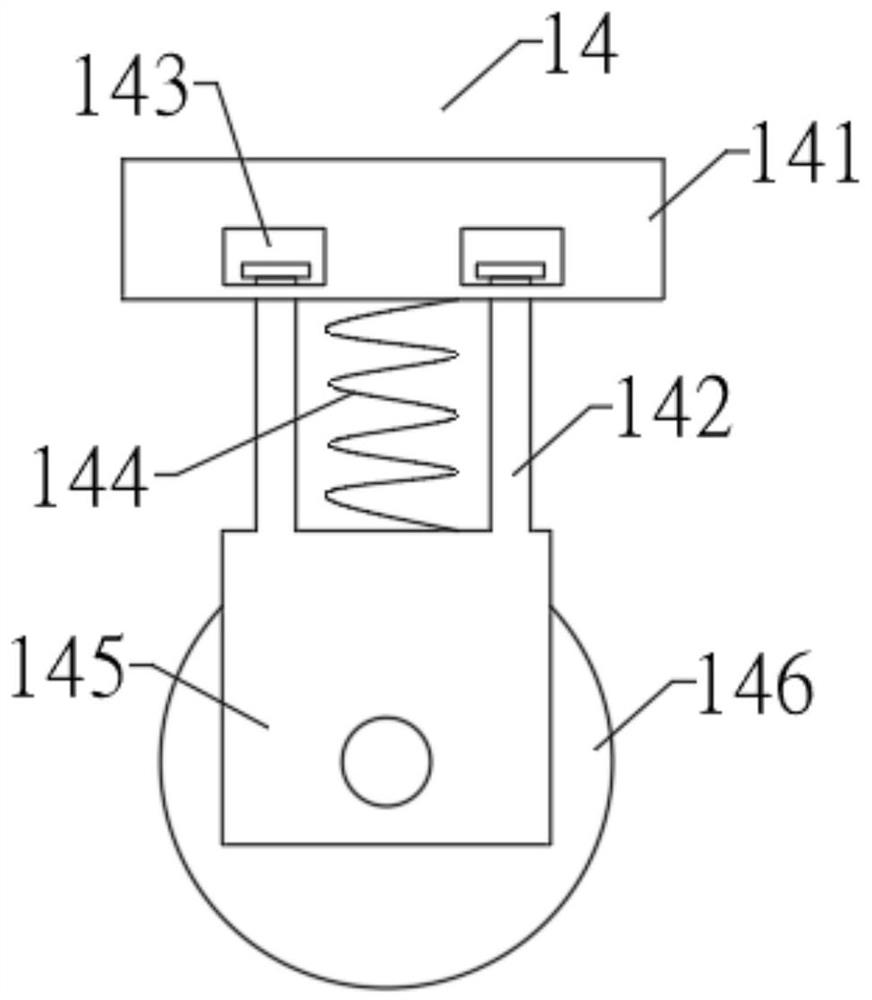

The invention discloses an energy-saving and environment-friendly plastic chemical production equipment, which comprises a container, the container adopts a gourd-shaped structure, a plurality of supporting feet are fixedly connected to the outside of the bottom end of the container, and a clamping mechanism is arranged in the middle of the container , the clamping mechanism clamps a horizontally arranged screen, and the screen divides the interior of the container into two spaces, the upper and the lower. In the present invention, a mesh plate is arranged, and the mesh plate divides the inside of the container into upper and lower spaces. When the material in the upper space has a small particle size after processing, it can pass through the mesh plate and drop into the lower space for further processing, so as to avoid large particle differences. The problem of uneven processing caused by the mixing of different plastics.

Description

An energy-saving and environmentally friendly plastic chemical production equipment technical field The present invention relates to plastic chemical production equipment technical field, relate in particular to a kind of plastic chemical production of energy saving and environmental protection equipment. Background technique Chemical equipment is a part of chemical machinery, and chemical machinery includes two parts, one of which is chemical machinery, mainly refers to Equipment such as fans, compressors, and various pumps for fluid conveying, the main components of which are moving machinery, generally called chemical machinery device. The second is that chemical equipment mainly refers to static machinery, such as separation equipment such as towers, containers, and reactor equipment. etc., sometimes referred to as non-standard equipment. The division of chemical machinery and other machinery is not very strict, for example, some are used in chemical Process ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J19/18

CPCB01J19/18Y02P20/10

Inventor 徐国想王苏广陆俊臣

Owner 无锡享源信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com