Energy-saving and environment-friendly plastic chemical production equipment

A technology for chemical production, energy saving and environmental protection, applied in the chemical industry, sustainable manufacturing/processing, chemical/physical/physical-chemical stationary reactors, etc. and other problems, to avoid the interruption of plastic processing, to avoid incomplete plastic processing, and to facilitate cleaning or replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

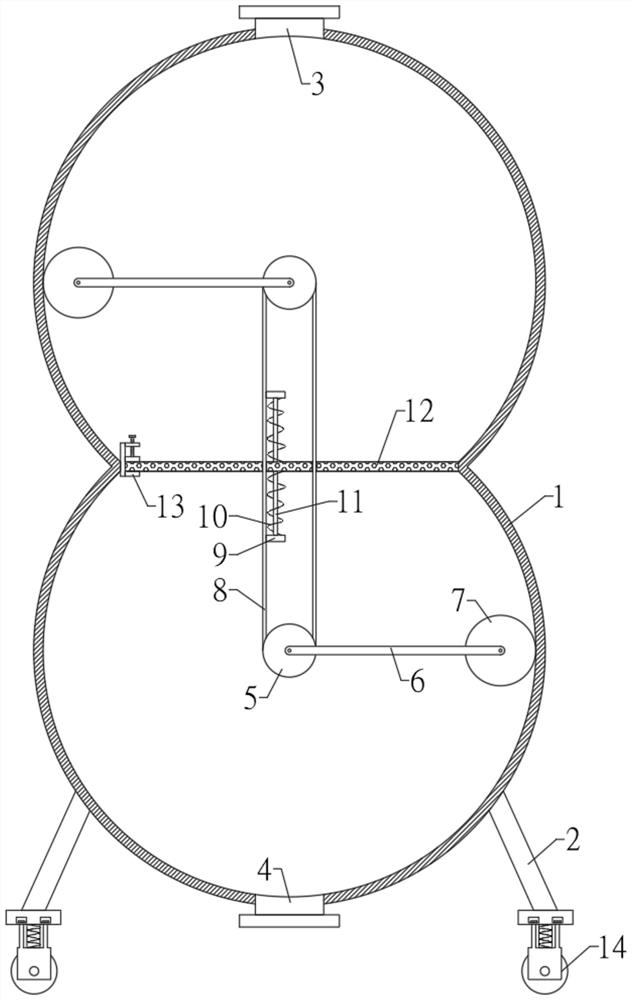

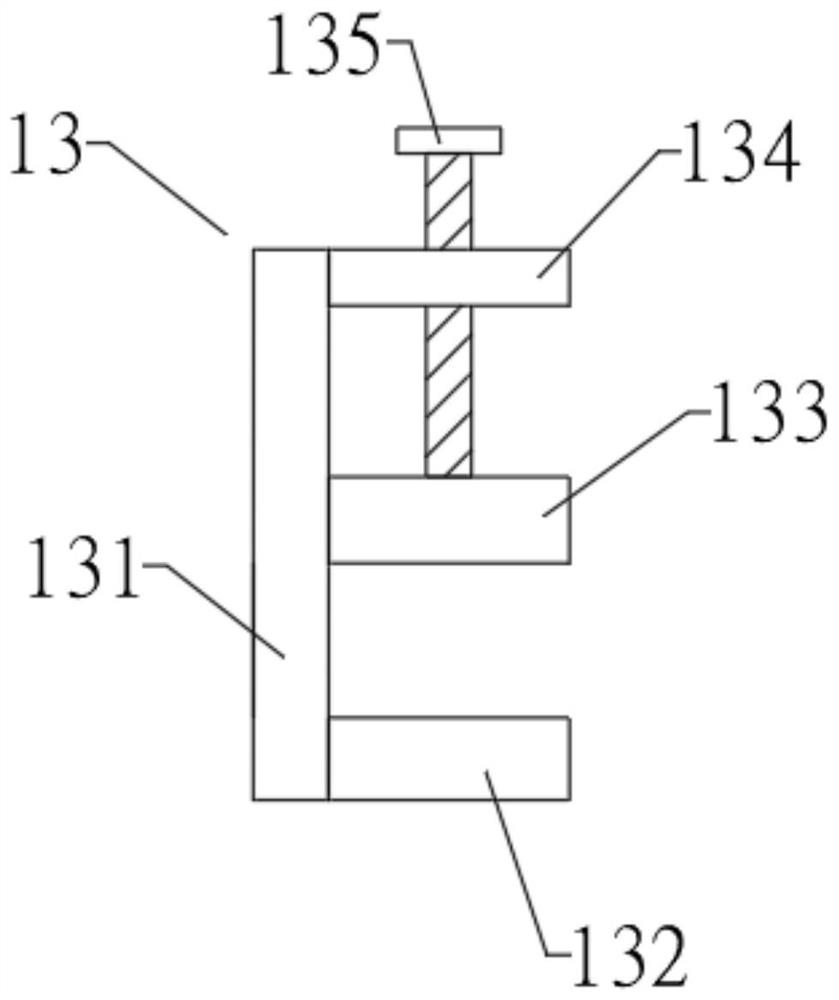

[0032] refer to Figure 1-3 , an energy-saving and environment-friendly plastic chemical production equipment, comprising a container 1, the container 1 adopts a gourd-shaped structure, a plurality of support feet 2 are fixedly connected to the outside of the bottom end of the container 1, and a buffer walking mechanism 14 is arranged on the bottom end of the support feet 2, Buffer walking mechanism 14 is made of top plate 141, pull bar 142, spring shock absorber 144, slotting 143, base 145 and road wheel 146. The top plate 141 is fixedly connected with the bottom end of the supporting foot 2, the top plate 141 is provided with a slot 143, the sliding wheel in the slot 143 is connected with a pull rod 142 adopting a T-shaped structure, and the end of the pull rod 142 away from the top plate 141 is fixedly connected with a base 145, A running wheel 146 is rotatably connected to the base 145 , and a spring shock absorber 144 is fixedly connected between the base 145 and the top ...

Embodiment 2

[0038] refer to Figure 4-5 , The difference between this embodiment and Embodiment 1 is that the connecting rod 6 adopts a telescopic connecting rod, and the telescopic connecting rod consists of a first rod body 61, a second rod body 62, a stopper 63, a sliding rod 64, a return spring 65, a first fixed plate 66 and the second fixed plate 67 constitute. The first rod body 61 is fixedly connected with the transmission wheel 5, the second rod body 62 is rotationally connected with the drum 7, the second rod body 62 is fixedly connected with the first fixed plate 66, and the second rod body 62 is vertically arranged with the first fixed plate 66, the first The rod body 61 is fixedly connected with a second fixed plate 67, and the first rod body 61 and the second fixed plate 67 are vertically arranged, and the second fixed plate 67 is fixedly connected with two sliding rods 64 symmetrically, and the sliding rod 64 is fixedly connected with a stopper 63 , the slide bar 64 is slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com