Tail gas desulfurization and denitrification system and tail gas desulfurization and denitrification treatment process

A technology for desulfurization, denitrification, and exhaust gas, which is applied in the directions of gas treatment, exhaust equipment, and air quality improvement. It can solve the problems of increased volume of the exhaust gas treatment system, increased ship operating costs, and difficulty in ship space layout, reducing input costs and maintenance. Cost, saving layout space, high removal rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation of the tail gas desulfurization and denitrification system and the tail gas desulfurization and denitrification treatment method of the present invention will be described in detail below in conjunction with the accompanying drawings.

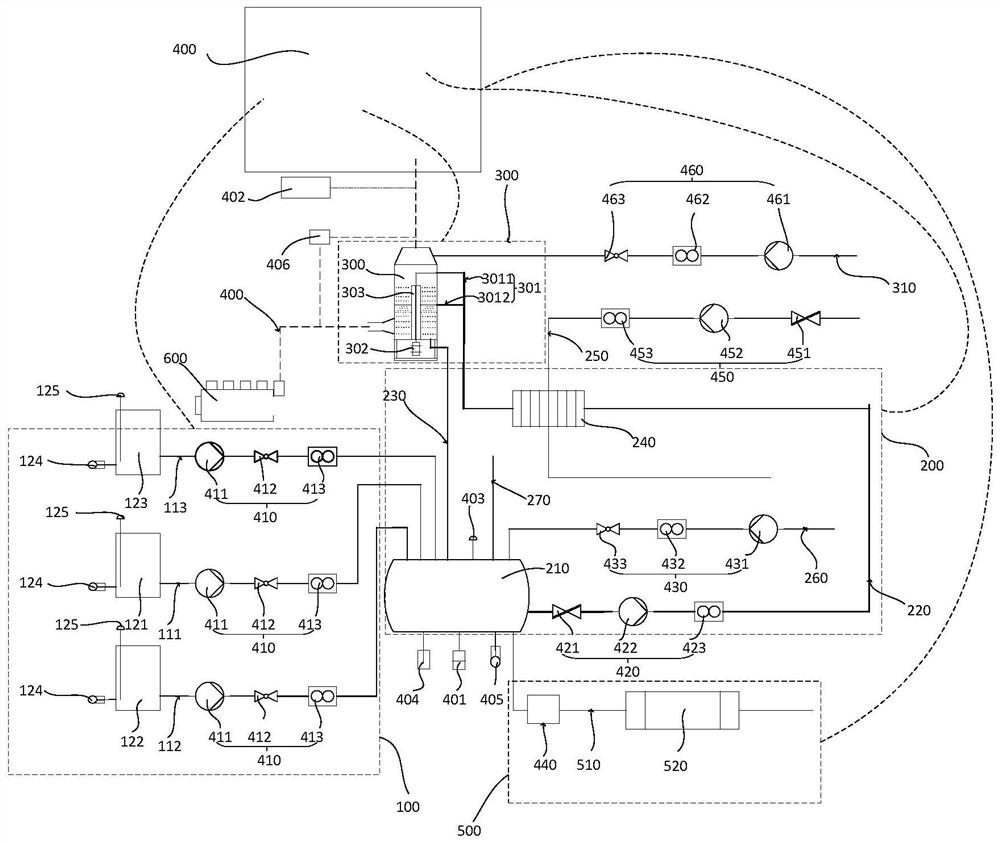

[0055] see figure 1 . The present invention provides a tail gas desulfurization and denitrification system, which is used for treating the tail gas of a marine diesel engine 600 . In the embodiment of the present invention, the tail gas desulfurization and denitrification system includes: a supply unit 100 , a reaction liquid circulation unit 200 , a reactor 300 , a control unit 400 and a waste liquid treatment unit 500 .

[0056] Such as figure 1 As shown, the supply unit 100 is fluidly connected to the reaction liquid circulation unit 200, the reaction liquid circulation unit 200 is fluidly connected to the reactor 300, and the waste liquid treatment unit 500 is connected to the reaction liquid circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com