Circuit board installation shell based on drying protection mechanism

A protection mechanism and circuit board technology, which is applied in the direction of casing/cabinet/drawer parts, electrical equipment casing/cabinet/drawer, electrical components, etc. Reduce the service life and other problems, achieve the effect of buffering the damage of the circuit board, prolonging the service life and improving the drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

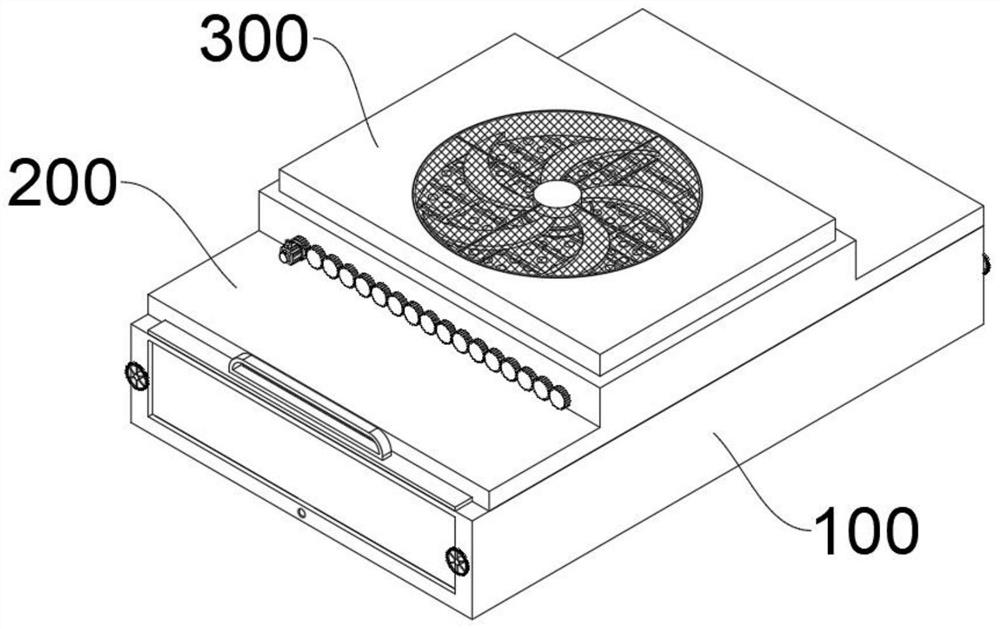

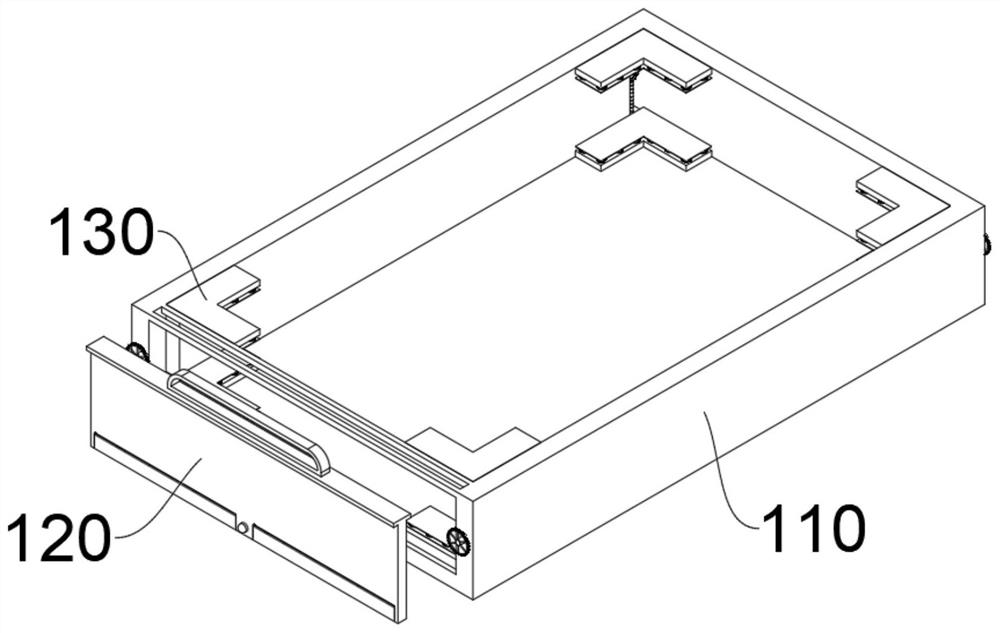

[0045] see Figure 1-Figure 13 As shown, the present embodiment provides a circuit board mounting case based on a desiccation protection mechanism, at least including:

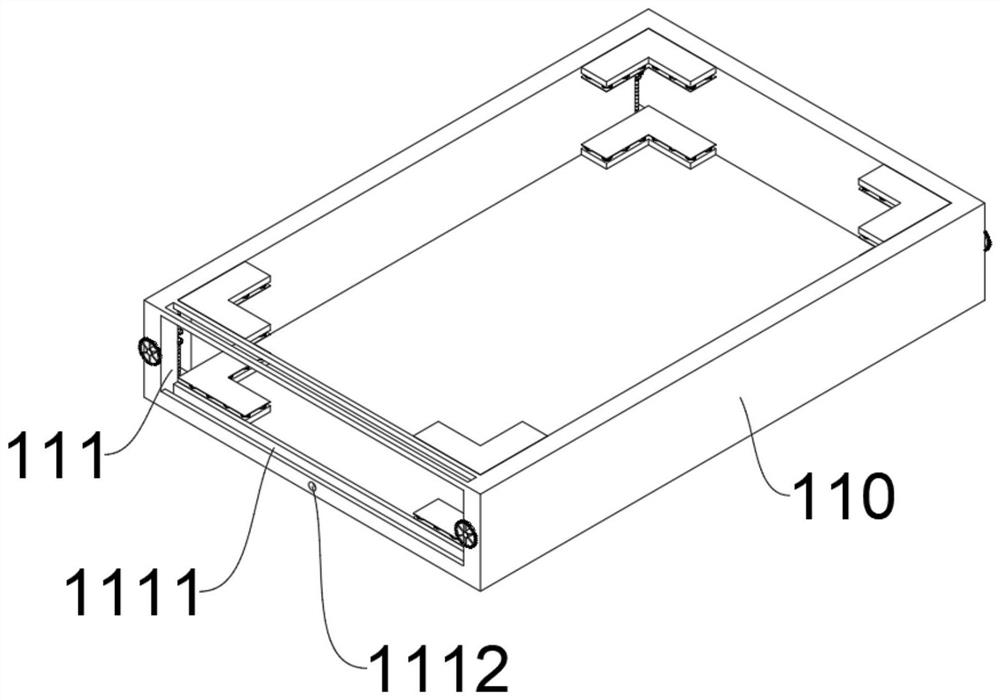

[0046] Install the protective mechanism 100, the installation protective mechanism 100 includes a protective shell 110, the end of the protective shell 110 is provided with a mounting groove 111, through the mounting groove 111, the circuit board can be inserted into the protective shell 110 from the inside of the mounting groove 111, which is convenient for installation, and the mounting groove 111 The inside is provided with a slot 1111, and the inside of the slot 1111 is inserted with a plugboard 120. Through the plugboard 120, after the circuit board is put into the inside of the protective case 110, the plugboard 120 can be inserted into the inside of the slot 1111, and the installation slot 111 Blocking not only prevents the circuit board from slipping out, but also prevents dust from entering the protec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com