Connector and connector assembly using same

A technology for connectors and contact parts, which is applied to the parts, connections, and protective grounding/shielding devices of connecting devices. Shielding mesh and other issues to prevent movement and offset, enhance the shielding effect, and make installation less difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

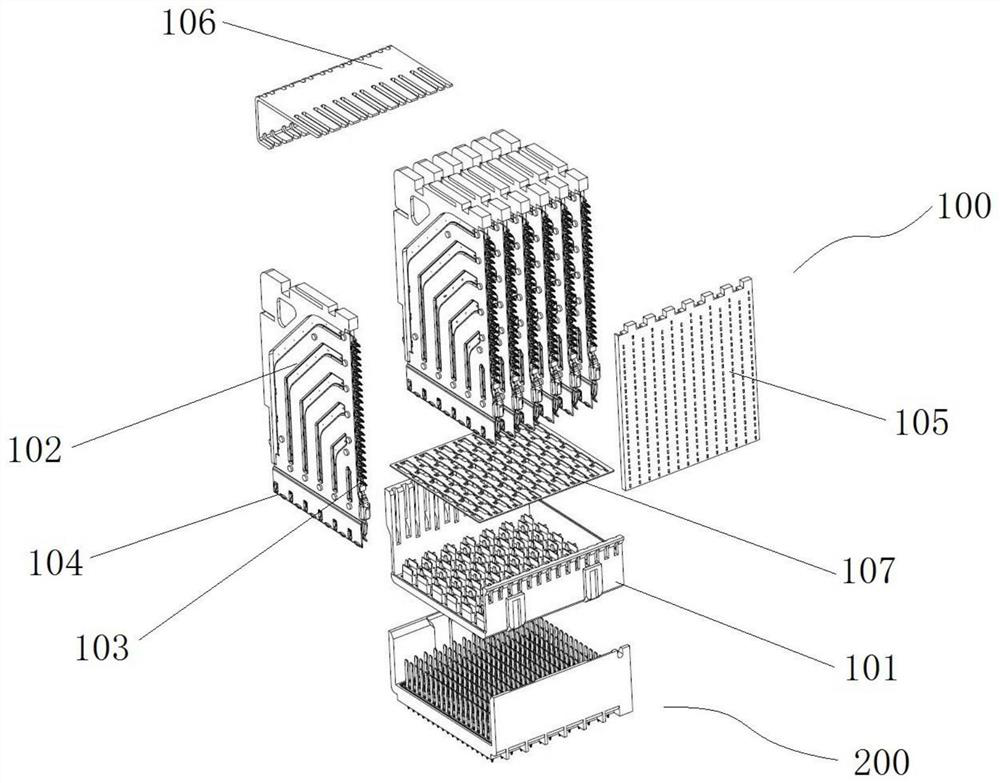

[0102] Such as figure 1 As shown, the connector assembly includes a female connector 100 and a male connector 200 that are mated to each other. Here, whether it is the female connector 100 or the male connector 200, the end used for insertion is the front end. .

[0103] The female end connector 100 includes a female end housing 101 and a plurality of terminal modules 102 arranged on the female end housing 101, wherein the terminal module 102 has a mounting end 103 and a mating end 104, and the mounting end 103 is used for fixed installation on a printed circuit board. On the board, the mating end 104 is used for mating with the male end connector 200 . The terminal modules 102 are generally square plates, and the terminal modules 102 are arranged in sequence along the thickness direction of the terminal modules 102 .

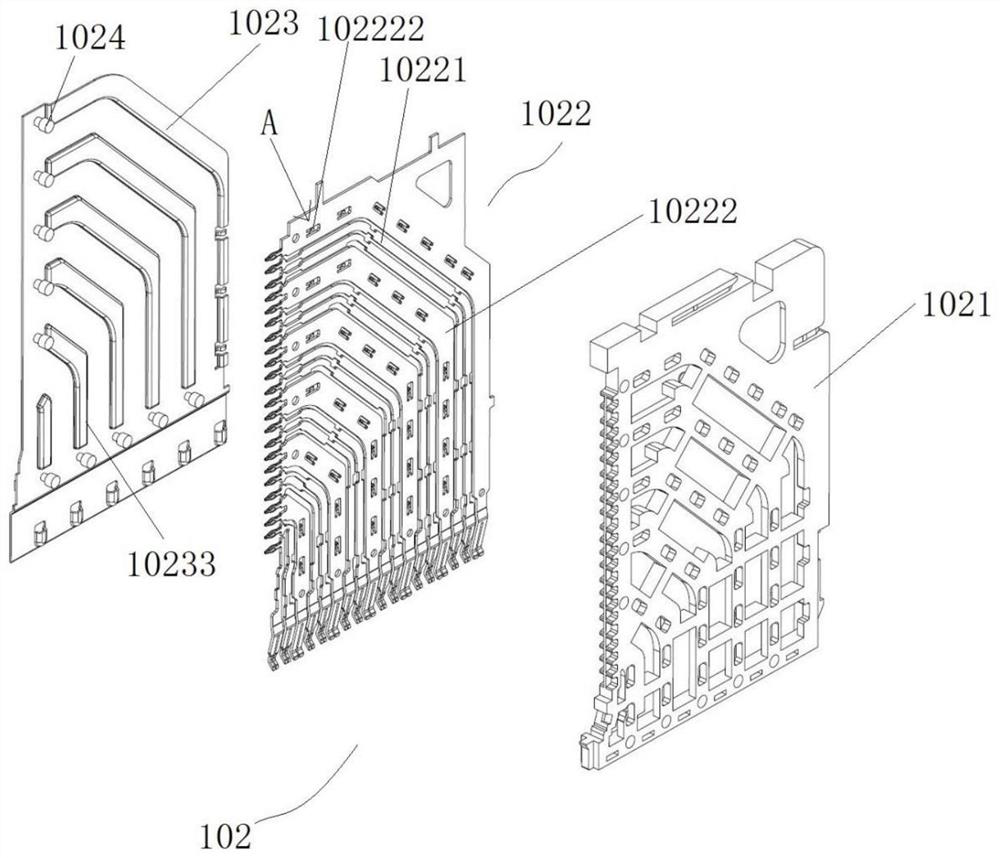

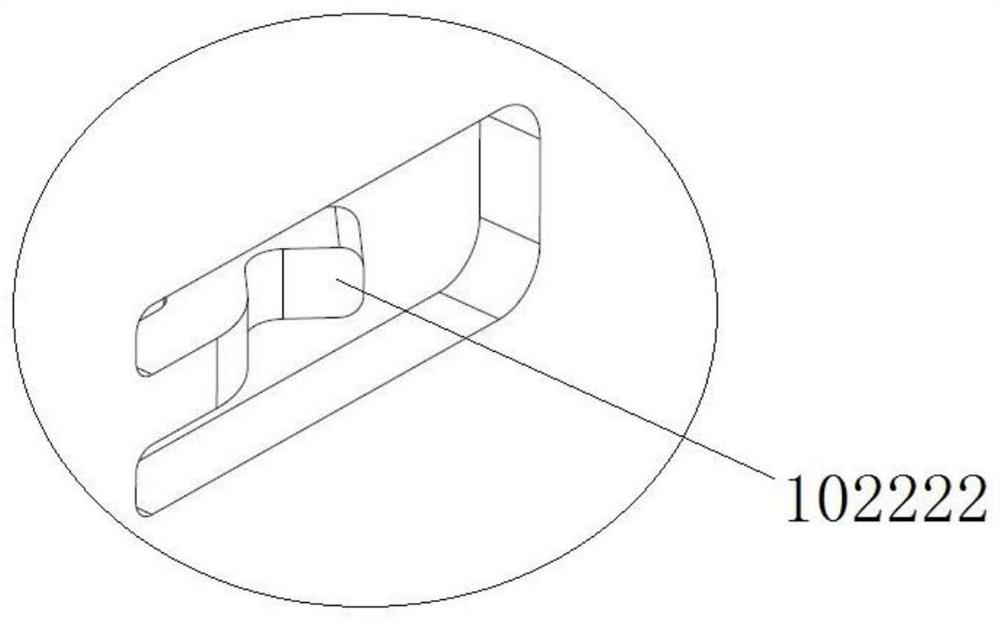

[0104] The structure of the terminal module 102 is as Figure 2 to Figure 10 As shown, the terminal module 102 includes a support frame 1021 , a terminal pa...

Embodiment 1

[0134] In Embodiment 1, the transverse shielding body is a transverse shielding sheet whose thickness direction is longitudinal. In this embodiment, the shape of the lateral shielding body can be changed, for example, it can be a columnar structure, and its cross section can be circular, square or other irregular shapes, the purpose of which is to separate two adjacent terminal rows.

[0135] Likewise, in Embodiment 1, the longitudinal shielding body is a longitudinal shielding sheet whose thickness direction is transverse. In this embodiment, the shape of the longitudinal shielding body can be changed, for example, it can be a columnar structure, and its cross-section can be circular, square or other irregular shapes. The purpose is to electrically connect each horizontal shielding body to form a complete common ground loop.

specific Embodiment 3

[0137] In Embodiment 1, there are two longitudinal shields, and the two longitudinal shields are located at both ends of each transverse shield. In this embodiment, there may be only one longitudinal shield, or the longitudinal shield may be omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com