Carbon dioxide sensor and preparation method thereof

A carbon dioxide, sensor technology, applied in semiconductor/solid-state device manufacturing, instruments, diodes, etc., can solve the problems of short service life, expensive processing, narrow detection range of gas sensors, and achieve good biocompatibility and environmental friendliness , Reduce the etching process, the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the following will further clearly and completely describe the present invention in conjunction with the embodiments of the present invention and the accompanying drawings; obviously, the specific implementation described here Examples are only some of the embodiments of the present invention, rather than all embodiments; the technical solutions of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings, but the scope of protection is not limited thereto.

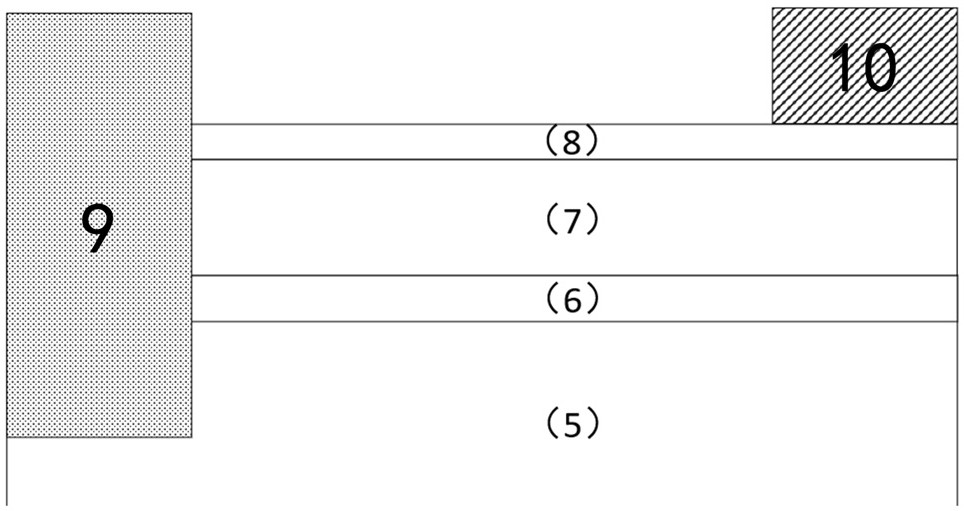

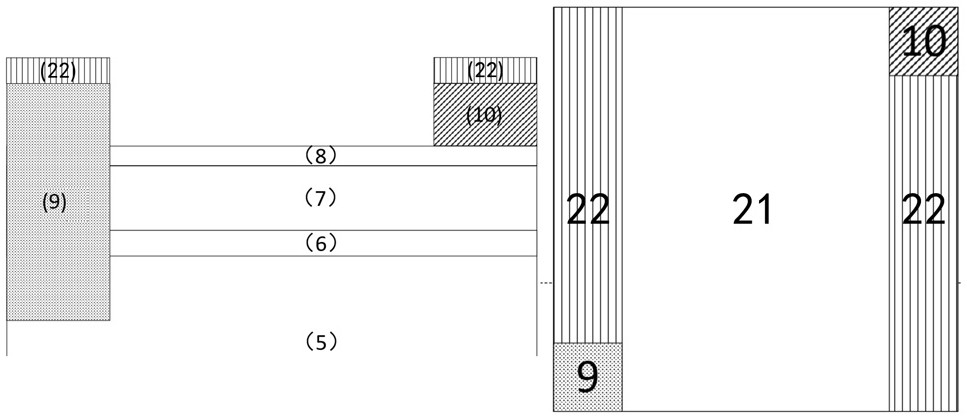

[0043] Such as Figure 1 to Figure 3 As shown, the carbon dioxide sensor provided by the present invention belongs to the technical field of gas sensors, and in particular relates to a new type of electrode manufacturing process and a carbon dioxide sensor with a wide detection range, which can be applied to a circuit for detecting ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com