Electrochemical testing device for erosion corrosion of special-shaped structure on inner wall of pipeline

A technology of erosion corrosion and testing equipment, which is applied in the direction of measuring equipment, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., can solve the problem that it is difficult to obtain electrochemical information of corrosion in special-shaped structure areas, it is difficult to respond to electrochemical information in special-shaped structure areas, and it is impossible to Research on the corrosion behavior of special-shaped structures and other issues, to achieve the effect of convenient connection, convenient installation and disassembly, and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

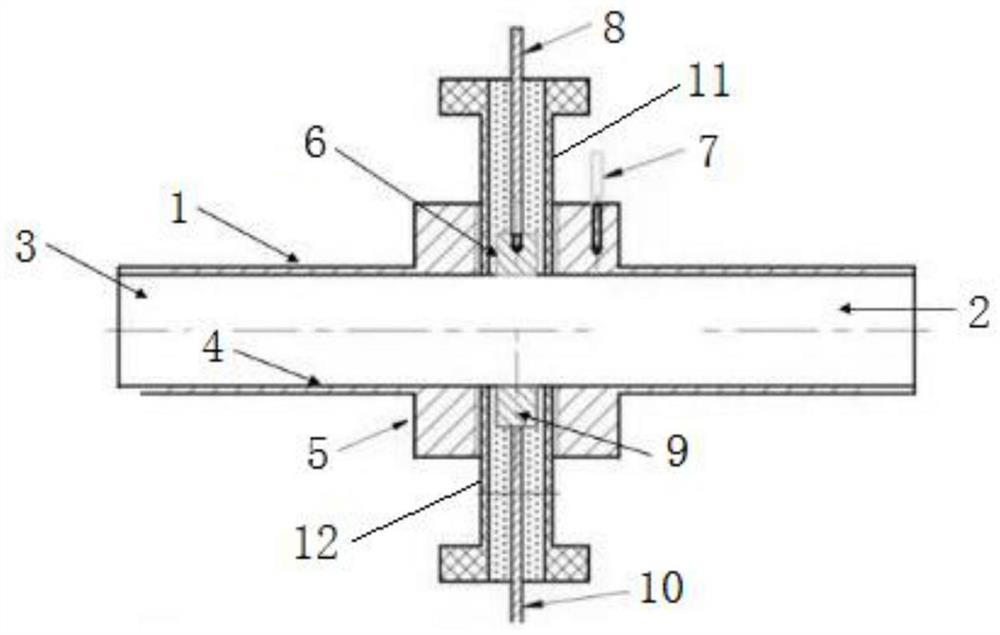

[0021]The erosion corrosion electrochemical test device for the special-shaped inner wall of the pipeline involved in this embodiment simulates a smooth inner wall structure, and its main structure includes an alloy pipeline 1, a water inlet 2, a water outlet 3, a coating 4, an electrode mounting seat 5, and a working electrode 6 , auxiliary electrode terminal rod 7, working electrode terminal rod 8, reference electrode 9 and reference electrode terminal rod 10; one end of the alloy pipeline 1 with a hollow cylindrical structure is the water inlet 2, and the other end is the water outlet 3, The inner wall of the alloy pipeline 1 is provided with a coating 4, and the outer wall is provided with an electrode mounting seat 5. One end of the electrode mounting seat 5 is provided with a working electrode 6 and an auxiliary electrode terminal rod 7. One end of the working electrode 6 is exposed to the alloy tube as a working surface. In the road 1, the other end is connected with the...

Embodiment 2

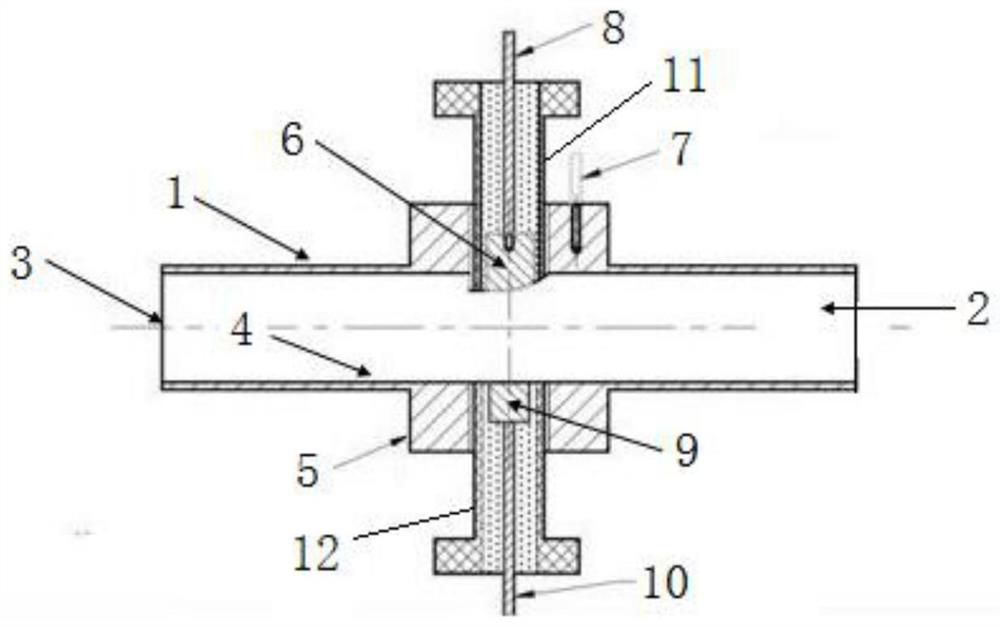

[0023] The erosion corrosion electrochemical test device for the special-shaped structure of the inner wall of the pipeline involved in this embodiment simulates a single-slope protruding structure, and its main structure is the same as that of Embodiment 1.

Embodiment 3

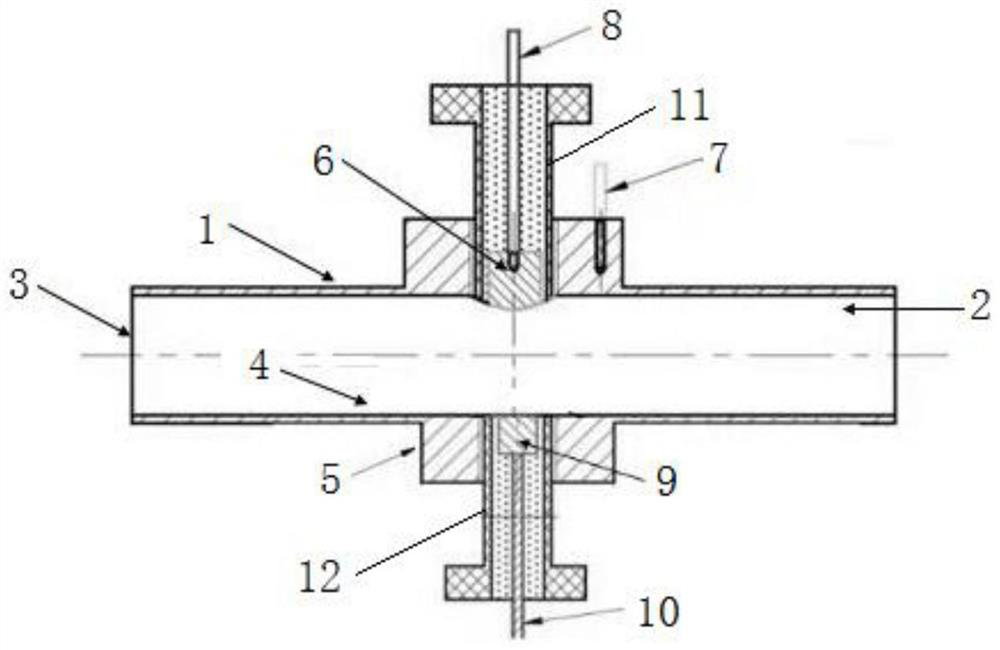

[0025] The erosion corrosion electrochemical test device for the special-shaped structure of the inner wall of the pipeline involved in this embodiment simulates a double-slope protruding structure, and its main structure is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com