Method for testing I-type fracture toughness of bonding interface of composite material bonding structure

A technology of fracture toughness and structural adhesive, which is applied in the field of testing the type I fracture toughness of the bonding interface, which can solve problems such as difficult test operations, and achieve the effects of strong controllability, convenient operation, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below by way of examples. The embodiments are only used to illustrate the content of the present invention and are not limited thereto. Those skilled in the art, due to the technical inspiration involved in the present invention, adopt equivalent replacements or equivalent deformations to form technical solutions that fall within the scope of the present invention within the scope of protection.

[0052] The present invention will be further described below in conjunction with the specific implementation process.

[0053] 1. Sample preparation

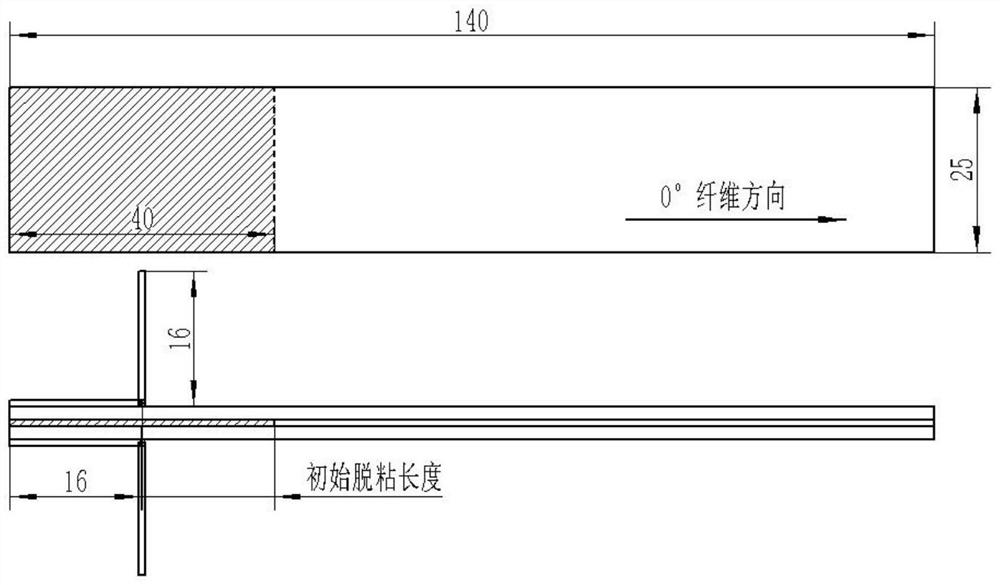

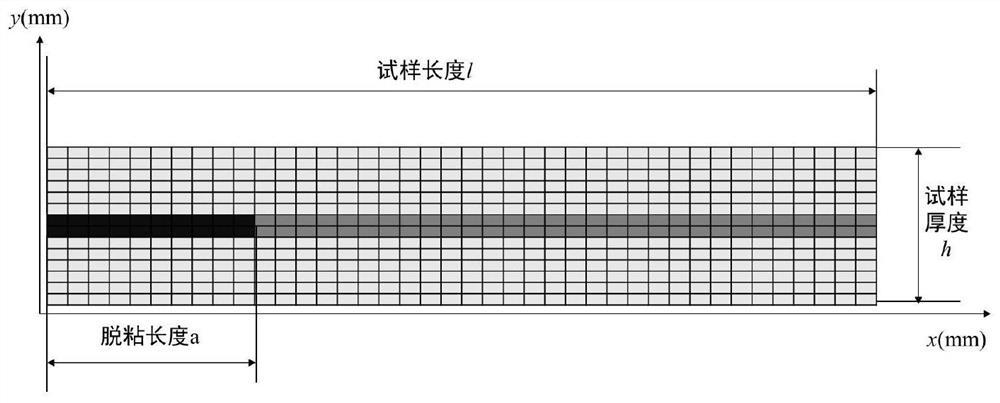

[0054] Such as figure 1 As shown, the geometric dimensions of the sample are 140mm long and 25mm wide. The composite material is AGMP3516 / T700, the adhesive is AGMA 020 adhesive, and the layup of the upper and lower composite material laminates is 16 layers, and the laying method is [0 / 45 / 90 / -45 / 0 / 45 / 90 / -45 / -45 / 90 / 45 / 0 / -45 / 90 / 45 / 0], the layup of the adhesive surface is 0°. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com