A method for evaluating residual stress distribution characteristics of natural gas pipeline girth welds using coercive force

A natural gas pipeline, residual stress technology, applied in the direction of using stable tension/pressure to test material strength, force/torque/work measuring instruments, instruments, etc., can solve the high requirements of ultrasonic measurement conditions, artificial drilling, pipeline damage and other problems, to achieve the effect of high evaluation efficiency, high precision and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

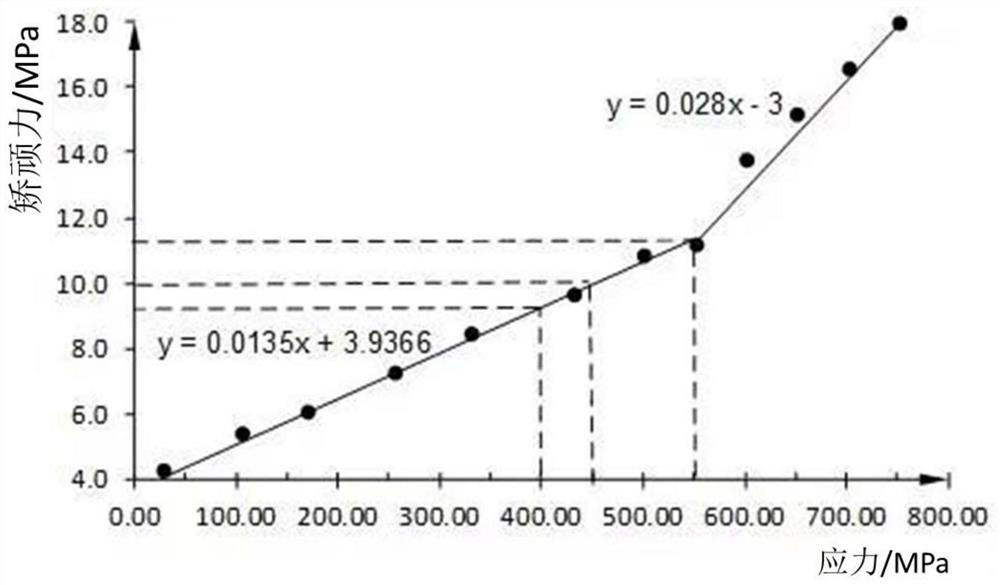

[0034] A method for evaluating residual stress distribution characteristics of a natural gas pipeline girth weld by using coercive force, which specifically includes the following steps:

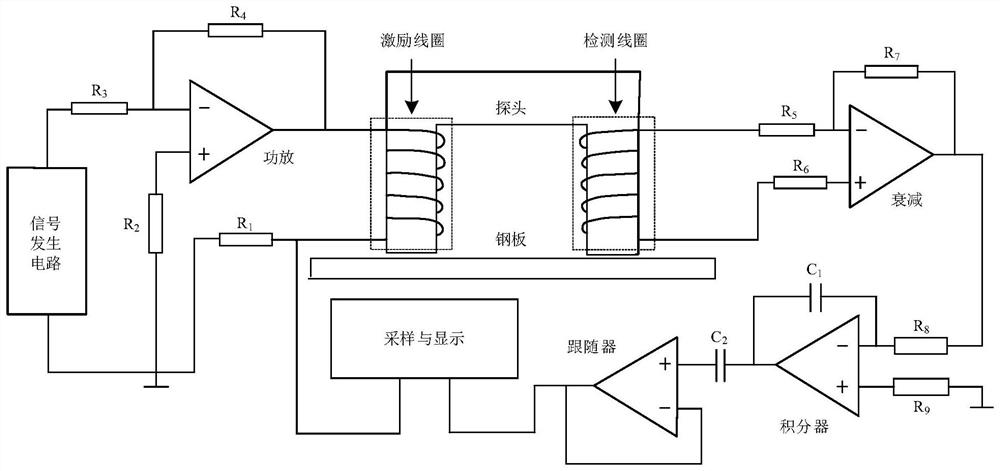

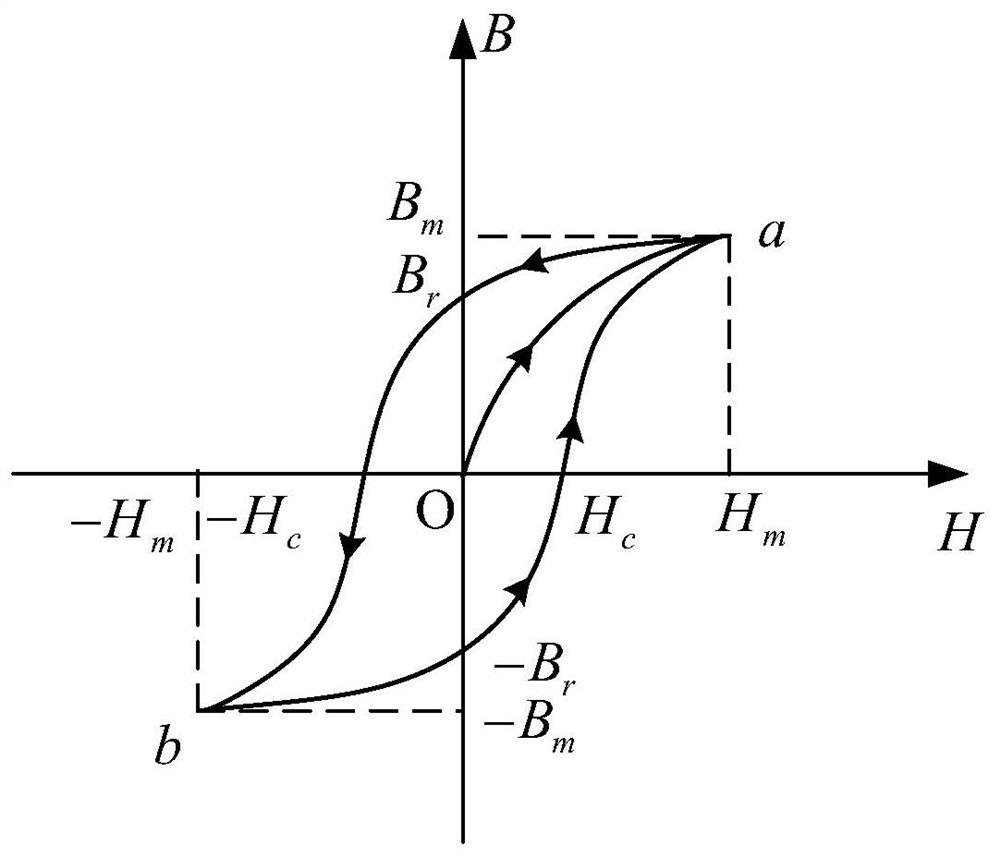

[0035] Step 1, the probe of the coercivity detection device is closely attached to the outer wall of the natural gas pipeline. In this embodiment, the coercivity detection device adopts a U-shaped probe, and the magnetic core of the U-shaped probe is made of manganese-zinc ferrite. The coils are wound on both sides of the magnetic core, and the induction coil can also be used as a detection coil to detect the change of the magnetic induction intensity in the magnetic circuit during the magnetization process; the probe and the outer wall of the natural gas pipeline form a closed loop, and the coercive force detection device is turned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com