Helium low-temperature purification method and device and helium refrigeration cycle system

A purification method and technology of purification device, which are applied in the field of helium low temperature purification and helium refrigeration cycle system, can solve the problems of low temperature system performance degradation, inability to meet application occasions, small size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]An embodiment of the present invention provides a low-temperature purification method for helium gas. The method performs low-temperature purification of helium gas through a pipeline system, and sequentially connects a precooling heat exchanger, a low-temperature heat exchanger, and a purifier installed in the pipeline system. That is to say, the low-temperature purification method for helium in this embodiment can be implemented on any equipment in the prior art that is equipped with a pre-cooling heat exchanger, a low-temperature heat exchanger, and a purifier, and the specific structure of the equipment is not included in the present invention. Do limit.

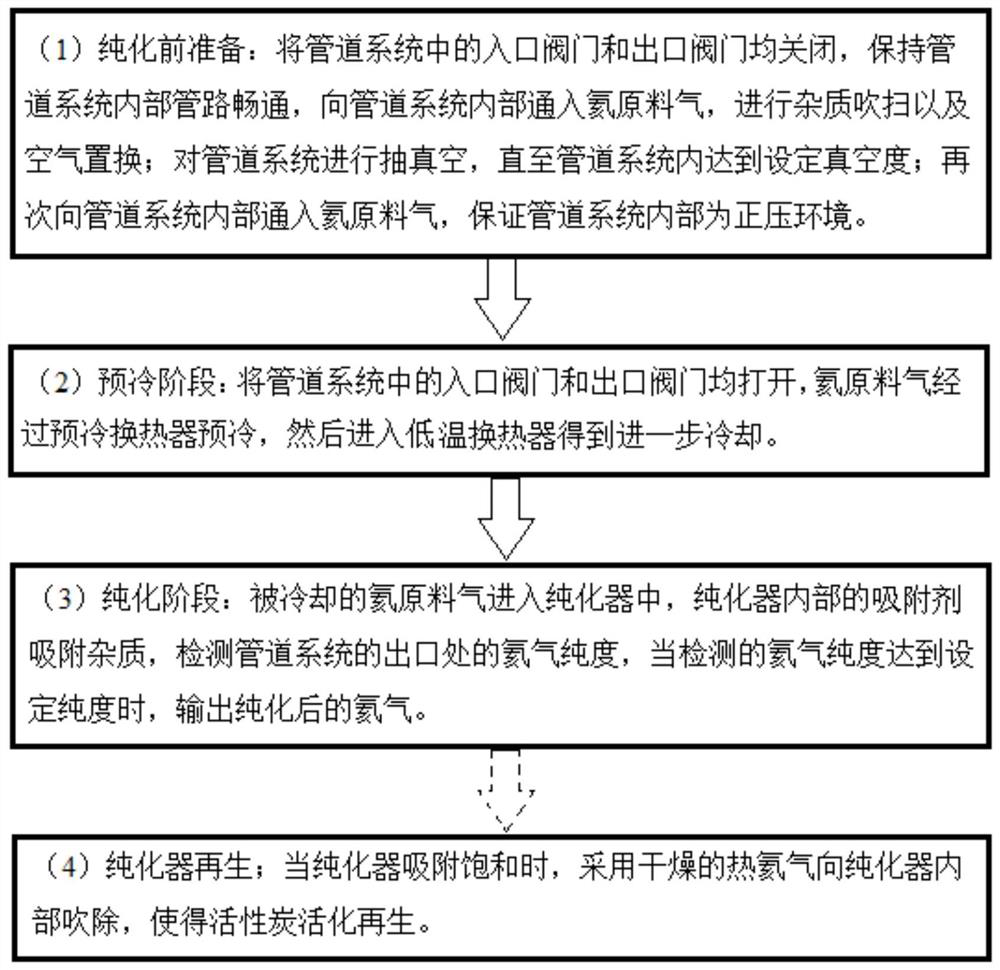

[0033] see figure 1 , the low-temperature purification method for helium comprises the steps of:

[0034] (1) Preparation before purification: close the inlet valve and outlet valve in the pipeline system, keep the pipeline inside the pipeline system unblocked, feed helium raw material gas into the pipeline system...

Embodiment 2

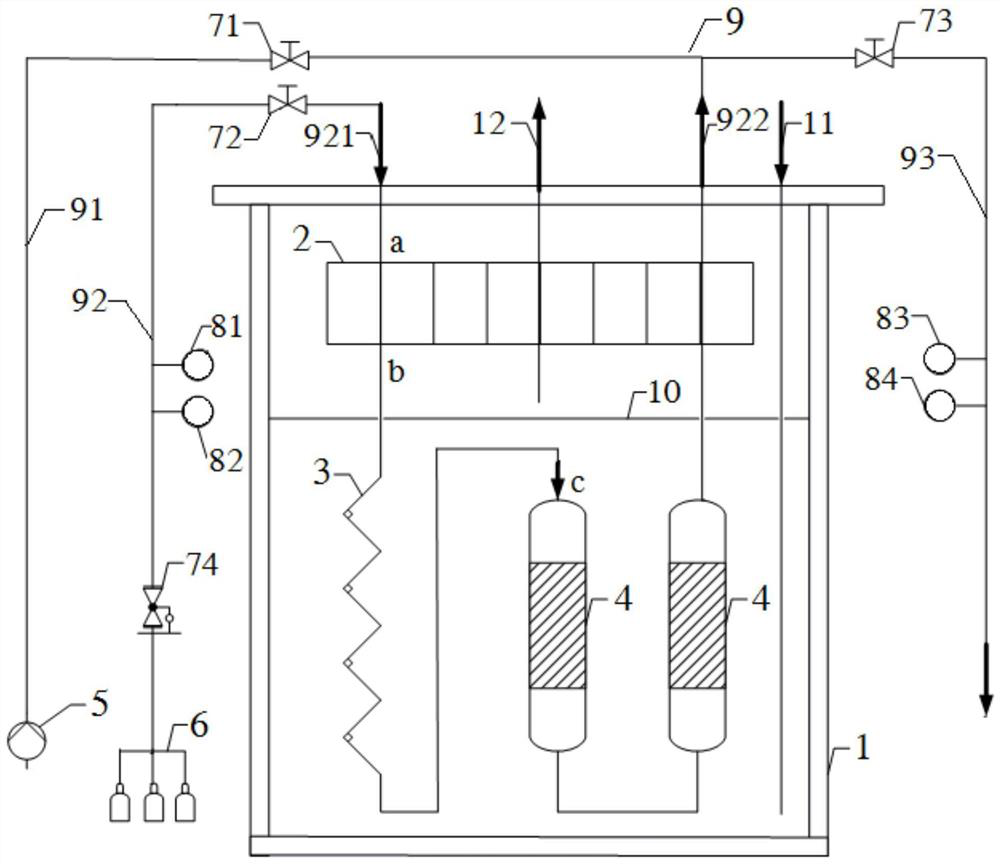

[0045] Based on the same inventive concept, this embodiment provides a preferred device for implementing the helium low-temperature purification method of the above-mentioned embodiment 1, see figure 2 , the helium low-temperature purification device includes a pipeline system 9, a precooling heat exchanger 2, a low-temperature heat exchanger 3, a purifier 4, a Dewar tank 1, a vacuum pump 5 and a helium cylinder group 6, and the above-mentioned pre-heating is carried out through the pipeline system 9. The cold heat exchanger 2, the cryogenic heat exchanger 3, the purifier 4, the Dewar tank 1, the vacuum pump 5 and the helium cylinder group 6 are connected as a whole. In order to improve the overall portability of the helium low-temperature purification device, as a preferred embodiment, the entire helium low-temperature purification device can be integrated on a trolley, which is flexible and convenient to move.

[0046] The specific piping structure of the pipeline system 9 ...

Embodiment 3

[0053] This embodiment provides a helium refrigeration cycle system used in a neon-helium extraction device, the helium gas used in the helium refrigeration cycle system is the helium gas with a purity of 6N produced by the low-temperature purification method for helium gas in the above-mentioned embodiment 1 , or the helium gas with a purity of 6N produced by the helium cryogenic purification device of the above-mentioned embodiment 2. 6N helium is sent into the helium refrigeration cycle system to participate in compression, expansion, and heat exchange, and provides cooling capacity for the neon and helium extraction device. Since the present invention does not improve other structures of the helium refrigeration cycle system and the neon-helium fine extraction device, other unspecified structures of the helium refrigeration cycle system and the neon-helium fine extraction device can refer to the prior art, and the specific content is here Explanation is not done.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com