Purification method of isopropanol for liquid chromatography-mass spectrometry

A technology of liquid chromatography and purification method, which is applied in the field of purification of isopropanol for liquid chromatography-mass spectrometry, can solve problems such as the inability to meet the high purity requirements of chromatographic grade reagents, and achieve the reduction of import costs and production The effect of simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

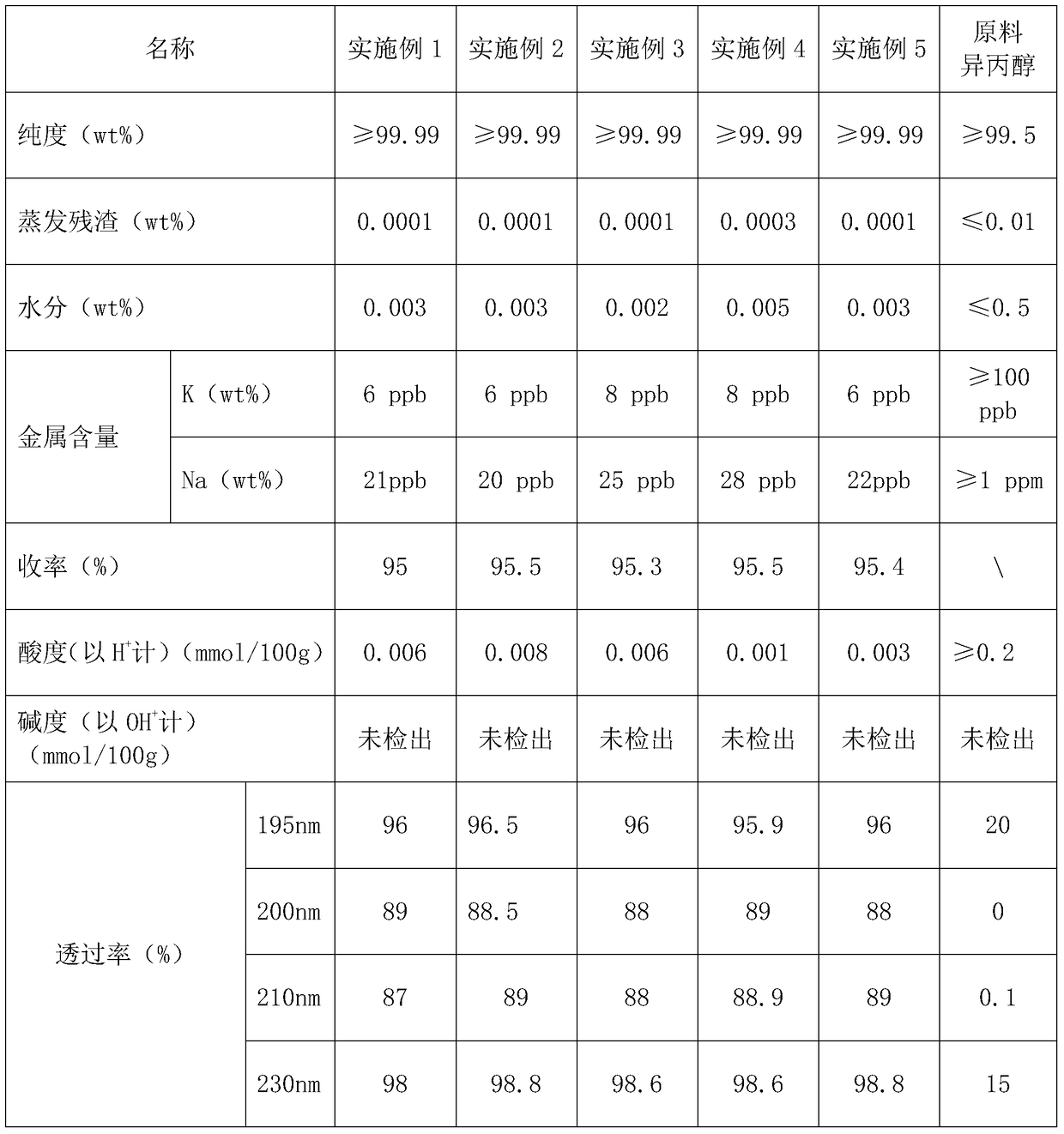

Examples

Embodiment 1

[0026] The purification method of isopropanol for liquid chromatography-mass spectrometry is characterized in that, comprises the steps:

[0027] a. Take the raw material isopropanol, add potassium permanganate to it for oxidation treatment, remove impurities containing double bonds such as ethylene, acrylonitrile, hydrocyanic acid, acrolein, methacrylonitrile, acryl alcohol, oxazole, acetonitrile Impurities such as amides. While adding potassium permanganate, add sodium hydroxide and calcium oxide to slow down the oxidation of potassium permanganate, neutralize the acidic substances produced by oxidation, and adjust the pH to 8. After the oxidation treatment, the isopropanol is quickly distilled off.

[0028] a'. Will add reducing agent ferrous oxide and stir in the isopropanol gained in step a, distill out isopropanol.

[0029] b. Add sodium carbonate to the distilled isopropanol to adjust the pH of the solution to 7, and shake to make the sodium carbonate fully react with...

Embodiment 2

[0037] The purification method of isopropanol for liquid chromatography-mass spectrometry is characterized in that, comprises the steps:

[0038]a. Take the raw material isopropanol, add potassium permanganate to it for oxidation treatment, remove impurities containing double bonds such as ethylene, acrylonitrile, hydrocyanic acid, acrolein, methacrylonitrile, acryl alcohol, oxazole, acetonitrile Impurities such as amides. While adding potassium permanganate, add sodium hydroxide and calcium oxide to slow down the oxidation of potassium permanganate, neutralize the acidic substances produced by oxidation, and adjust the pH to 14. After the oxidation treatment, the isopropanol is quickly distilled off.

[0039] a'. Add reducing agent sodium bisulfate and stir in the isopropanol gained in step a, distill out isopropanol.

[0040] b. Add potassium hydroxide to the above-mentioned distilled isopropanol to adjust the pH of the solution to 8, and shake to make potassium hydroxide ...

Embodiment 3

[0048] The purification method of isopropanol for liquid chromatography-mass spectrometry is characterized in that, comprises the steps:

[0049] a. Take the raw material isopropanol, add potassium permanganate to it for oxidation treatment, remove impurities containing double bonds such as ethylene, acrylonitrile, hydrocyanic acid, acrolein, methacrylonitrile, acryl alcohol, oxazole, acetonitrile Impurities such as amides. While adding potassium permanganate, add sodium hydroxide and calcium oxide to slow down the oxidation of potassium permanganate, neutralize the acidic substances produced by oxidation, and adjust the pH to 10. After the oxidation treatment, the isopropanol is quickly distilled off.

[0050] a'. Add reducing agent disodium hydrogen phosphate to the isopropanol obtained in step a and stir to distill out isopropanol.

[0051] b. Add sodium oxide to the distilled isopropanol to adjust the pH of the solution to 7.5, and shake to make the sodium oxide fully re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com