A kind of low thermal conductivity gold material and preparation method thereof, gold ware

A technology of gold material and low thermal conductivity, which is applied in the field of low thermal conductivity gold material and its preparation, can solve the problem of high thermal conductivity of high-purity gold material, and achieve good low thermal conductivity and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

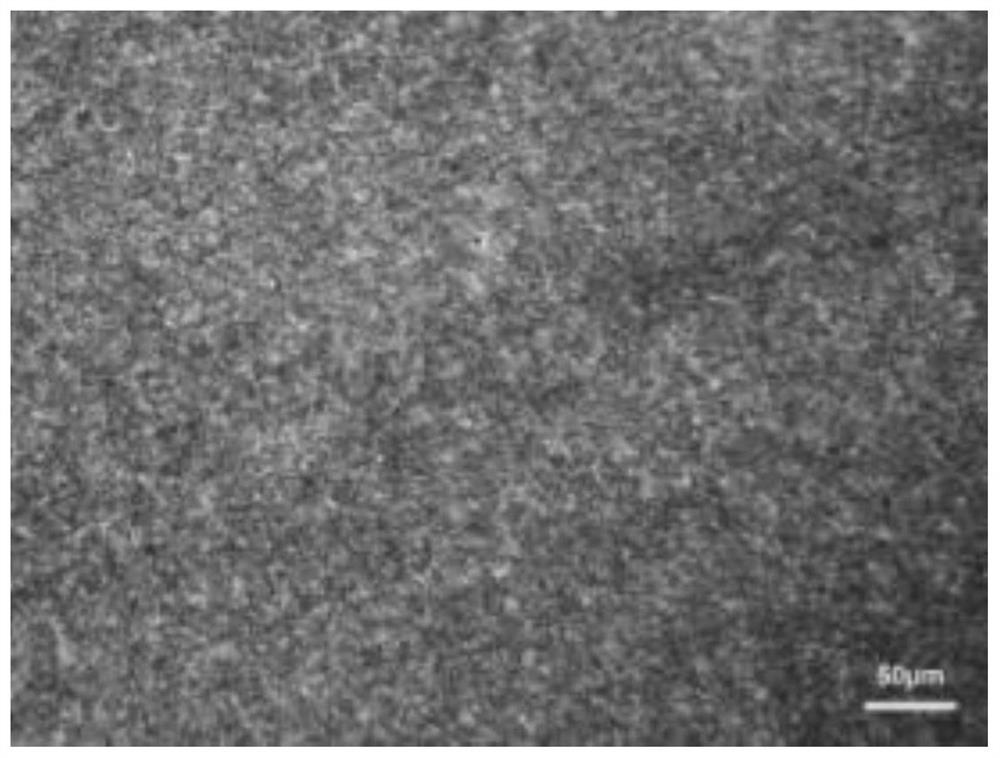

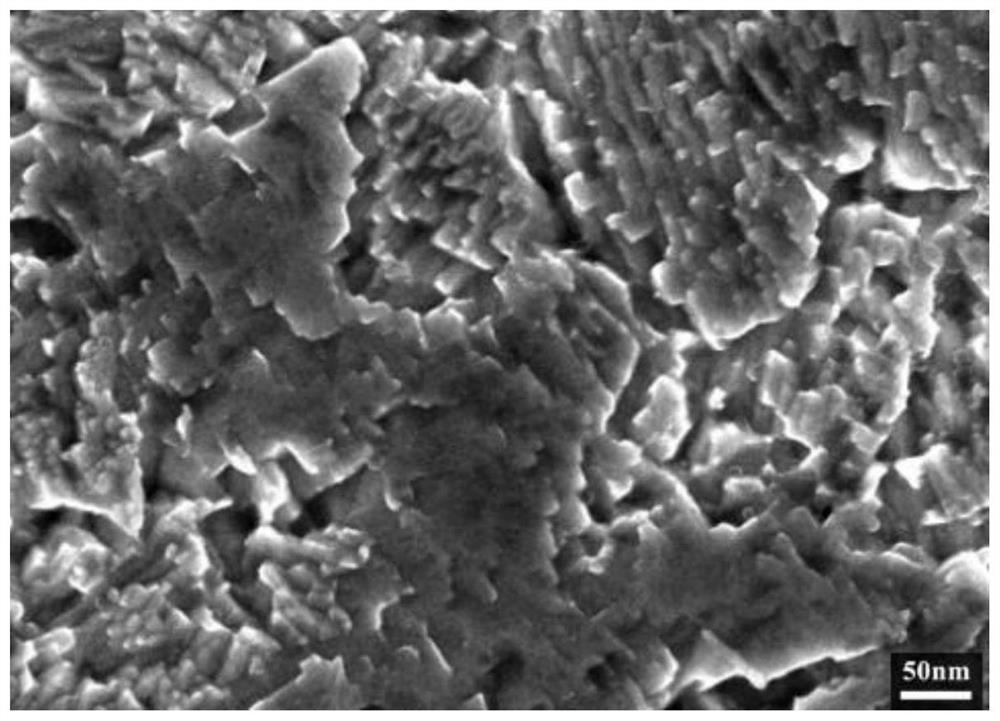

[0030] Preferably, the smelted gold material is obtained during smelting, and the preparation method further includes: mechanically rolling the smelted gold material to obtain a low thermal conductivity gold material. After smelting, mechanical rolling treatment is carried out to promote the grain refinement of the surface layer of the material, forming an extremely fine nanostructure, the interface between grains is greatly increased, the thermal resistance is increased, the thermal conductivity is lower, and the hardness of the material is better. Better strength. In the actual operation process, after the low thermal conductivity gold material is obtained through rolling and compaction, the low thermal conductivity gold material can be made into products of different shapes by using the conventional manufacturing process. Of course, after the smelted gold material is made into a gold product, rolling force can be applied to the surface of the product for rolling. This can ...

Embodiment 1

[0049] Low thermal conductivity gold material formula:

[0050] Au 99.99%

[0051] Ti 10ppm

[0052] V 90ppm

[0053] Wherein, the weight ratio of Ti and V is 1.2:8.8.

[0054] Mix according to the above formula and carry out smelting in the atmospheric environment according to the traditional method. The smelting temperature is 1200-1300°C to obtain the smelted gold material, which is rolled to form a gold plate with a thickness of 1mm; The rotational speed of the rolling head is ω=1900r / min, the lateral moving speed of the rolling head is v=8mm / min, the diameter of the rolling steel ball is 3mm, and the rolling depth is 0.15mm.

[0055] The nanostructure structure is obtained at a depth of about 70μm on the gold surface, and the average grain size is 20nm;

[0056] Thermal conductivity: Compared with Comparative Example 1, the thermal conductivity is reduced by 46%;

[0057] Mechanical properties: Hardness (HV): 105.

Embodiment 2

[0059] Low thermal conductivity gold material formula:

[0060] Au 99.99%

[0061] Cr 10ppm

[0062] V 90ppm

[0063] Wherein, the weight ratio of Cr and simple substance V is 1.5:8.5.

[0064] Mix according to the above formula and smelt in the atmosphere environment according to the traditional method. The smelting temperature is 1200-1300°C to obtain the smelted gold material, which is rolled to form a gold plate with a thickness of 1mm; The rotational speed of the rolling head is ω=1900r / min, the lateral moving speed of the rolling head is v=8mm / min, the diameter of the rolling steel ball is 3mm, and the rolling depth is 0.25mm.

[0065] The nanostructure structure is obtained at a depth of about 100μm on the gold surface, and the average grain size is 25nm;

[0066] Thermal conductivity: Compared with Comparative Example 1, the thermal conductivity is reduced by 43%;

[0067] Mechanical properties: Hardness (HV): 98.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com