Novel turbine engine

A turbine engine, a new type of technology, applied in the direction of engine components, engine cooling, machine/engine, etc., can solve the problems of reducing manufacturing costs and low working efficiency of a single impeller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

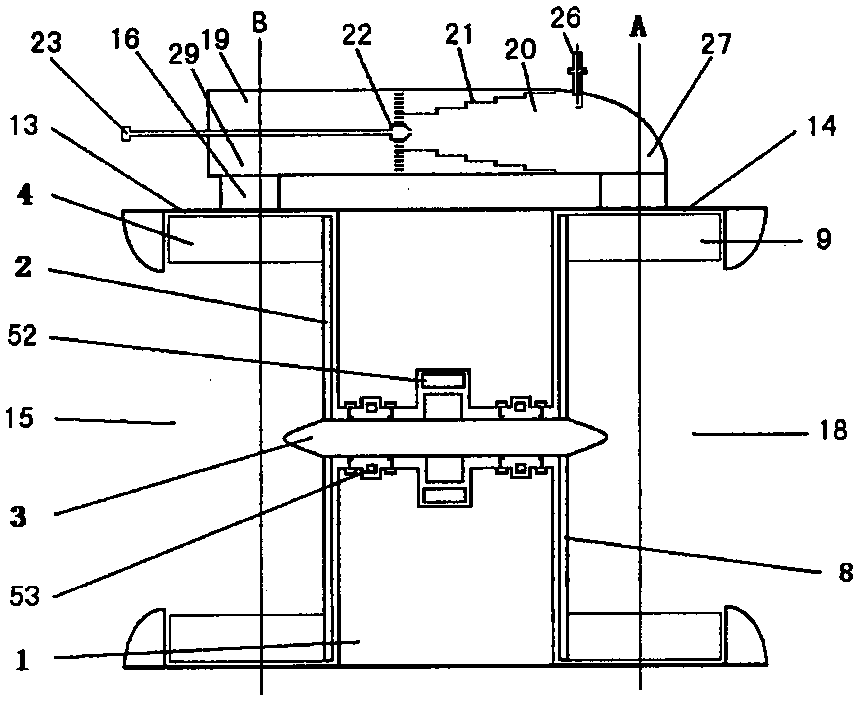

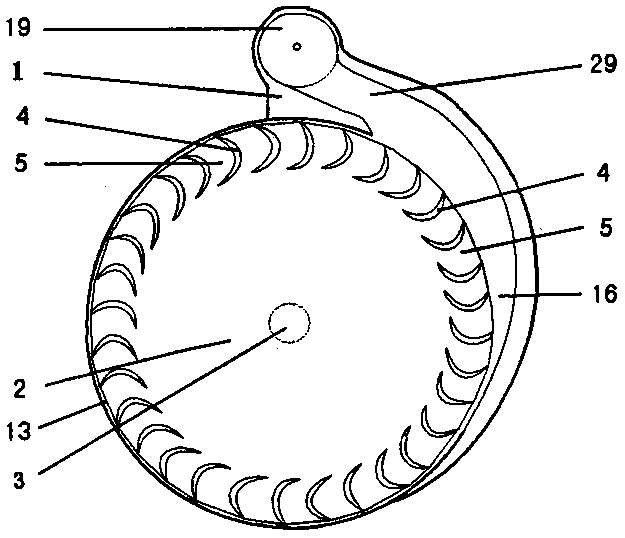

[0045] In order to more clearly illustrate the technical characteristics of this solution, the following thirteen embodiments are further elaborated on this solution in conjunction with the accompanying drawings.

[0046] Special note: Among the components and devices marked with numbers above, the components and devices marked with "first" are only used in the description of the following embodiments, such as the first compressor rotor, the first compressor wheel body, and the first compressor wheel Cavity, the first work rotor, the first work wheel body, the first work wheel cavity etc. are all called compressed air rotor, compressed air wheel body, compressed air wheel chamber, work rotor, work wheel body, work wheel cavity, other similarities and differences.

[0047] figure 1 , figure 2 , image 3The first embodiment of the program is shown together. As can be seen from the accompanying drawings, the new turbine engine shown in this embodiment is a basic power engine c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com