Online monitoring method for key process parameters of drying cylinder of paper machine

A technology of process parameters and paper machines, which is applied in the field of paper industry, can solve problems such as difficult online monitoring, achieve accurate operating conditions, and avoid the effect of "black box" operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

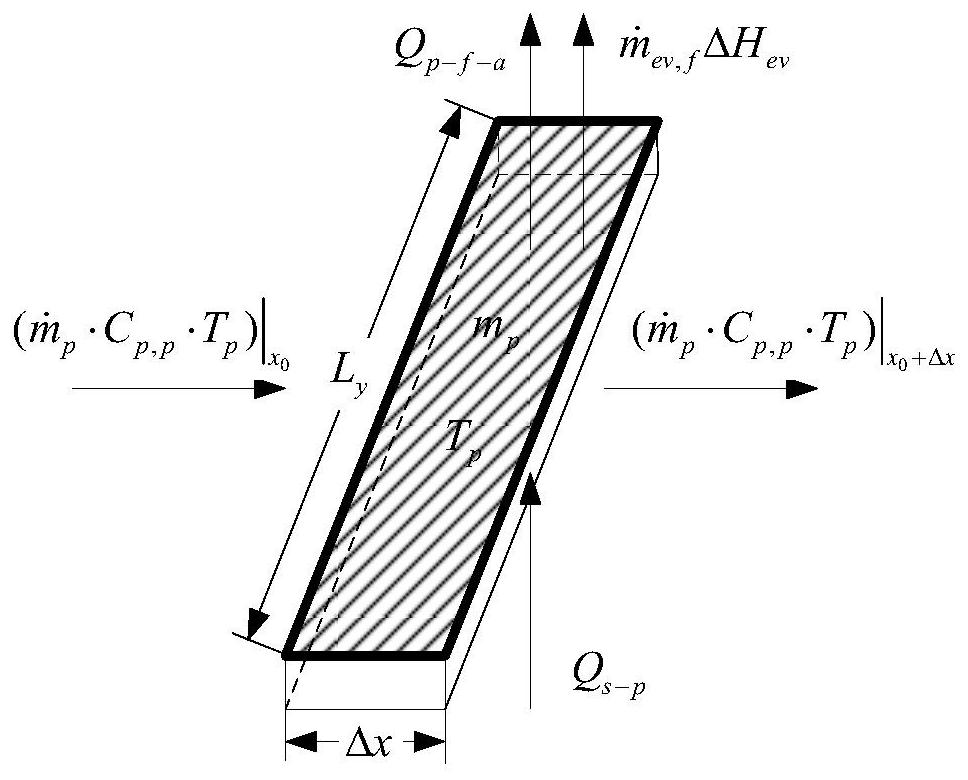

Method used

Image

Examples

Embodiment

[0119] The test object is the drying section of a paper machine that produces corrugated paper. The design capacity is 100,000 tons / year, the design speed is 500m / min, the width is 4m, and the main production weight is 105-145g / m 2 corrugated paper. The paper machine adopts a double-row multi-drying cylinder drying section, with a total of 48 drying cylinders (see appendix for details). Image 6 ), the dryers with a diameter of 1.5m are equipped with spoilers and fixed siphons. The steam condensate subsystem adopts a typical three-stage pressure reduction type, #23~#48 dryer is the main steam section (I section), #10~#22 dryer is the middle steam section (II section), #1~# 9 is the wet-stage steam section (section III). The ventilation and waste heat recovery subsystem adopts a closed air hood.

[0120] The types of dryers are shown in the table below:

[0121]

[0122]

[0123] Online collection of paper machine speed (V), paper basis weight (BW) o ), paper moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com