Sizing and drying integrated device for sizing machine

A technology of sizing machine and drying mechanism, which is applied in liquid/gas/steam removal by scraping method, textile material treatment, textile material carrier treatment, etc., which can solve problems such as impossibility of fabric soaking and sizing, waste of resources, and defective products , to achieve fast and uniform sizing operation, recycling energy, and reducing material removal time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

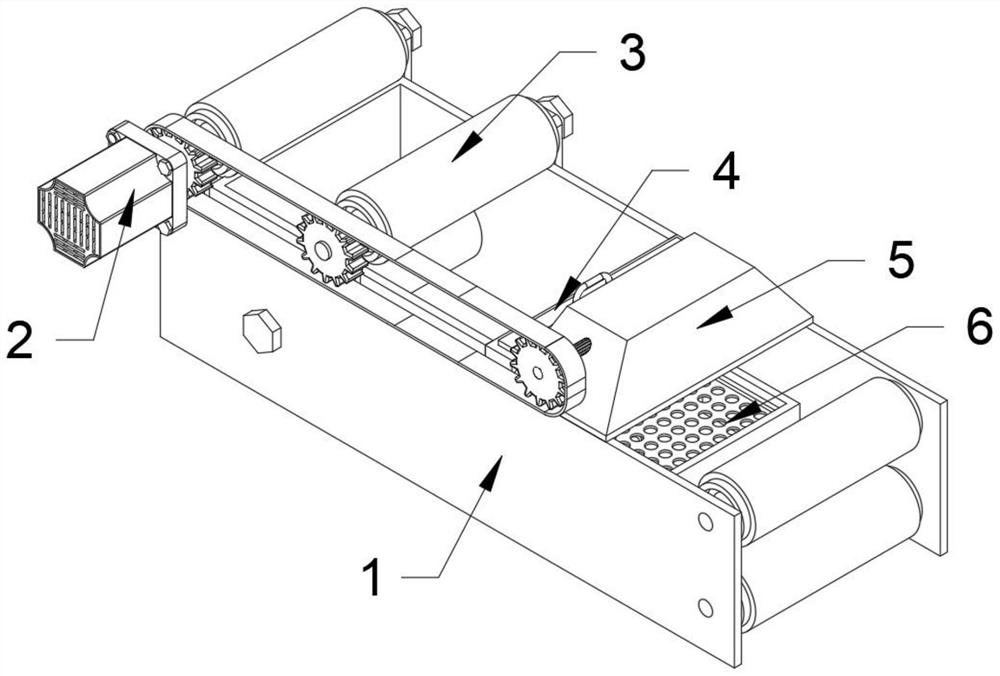

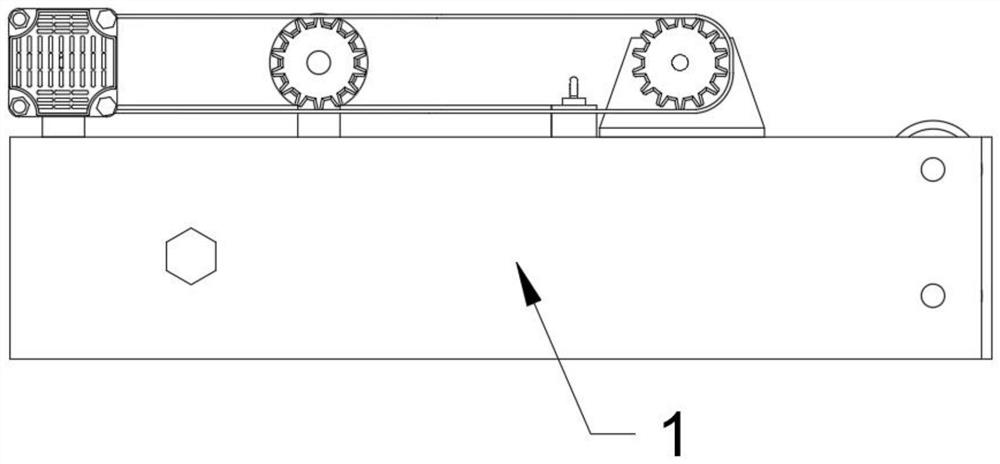

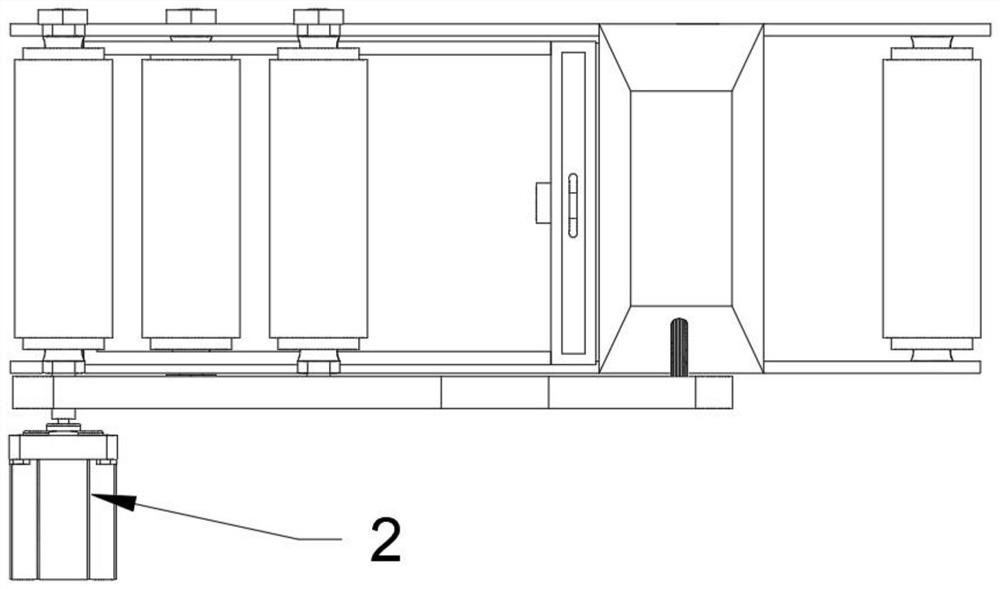

[0033] as attached figure 1 To attach Figure 9 Shown:

[0034] The present invention provides a sizing and drying integrated device for a sizing machine, comprising: a driving mechanism 2, a sizing and leveling mechanism 3, a squeegee mechanism 4, a drying mechanism 5, a residual sizing collecting mechanism 6, and a sizing and leveling mechanism 3 fixedly connected to the left side of the top surface of the processing table 1; the drying mechanism 5 is fixedly connected to the right side of the top surface of the processing table 1; The pulp collection mechanism 6 is fixedly connected to the inner side of the processing table 1, and the residual pulp collection mechanism 6 is located directly below the drying mechanism 5; the residual pulp collection mechanism 6 includes a box 601, an embedded filter screen 602 and a return Pipe 603, the inside of the box body 601 is clamped with an embedded filter screen 602, and the return pipe 603 is connected through the inner left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com