Die head of coating machine

A technology of coating machine and die head, which is applied in textile processing machine accessories, textile material processing, textiles and papermaking, etc. It can solve the problems of uneven size and large size consumption, and achieve the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

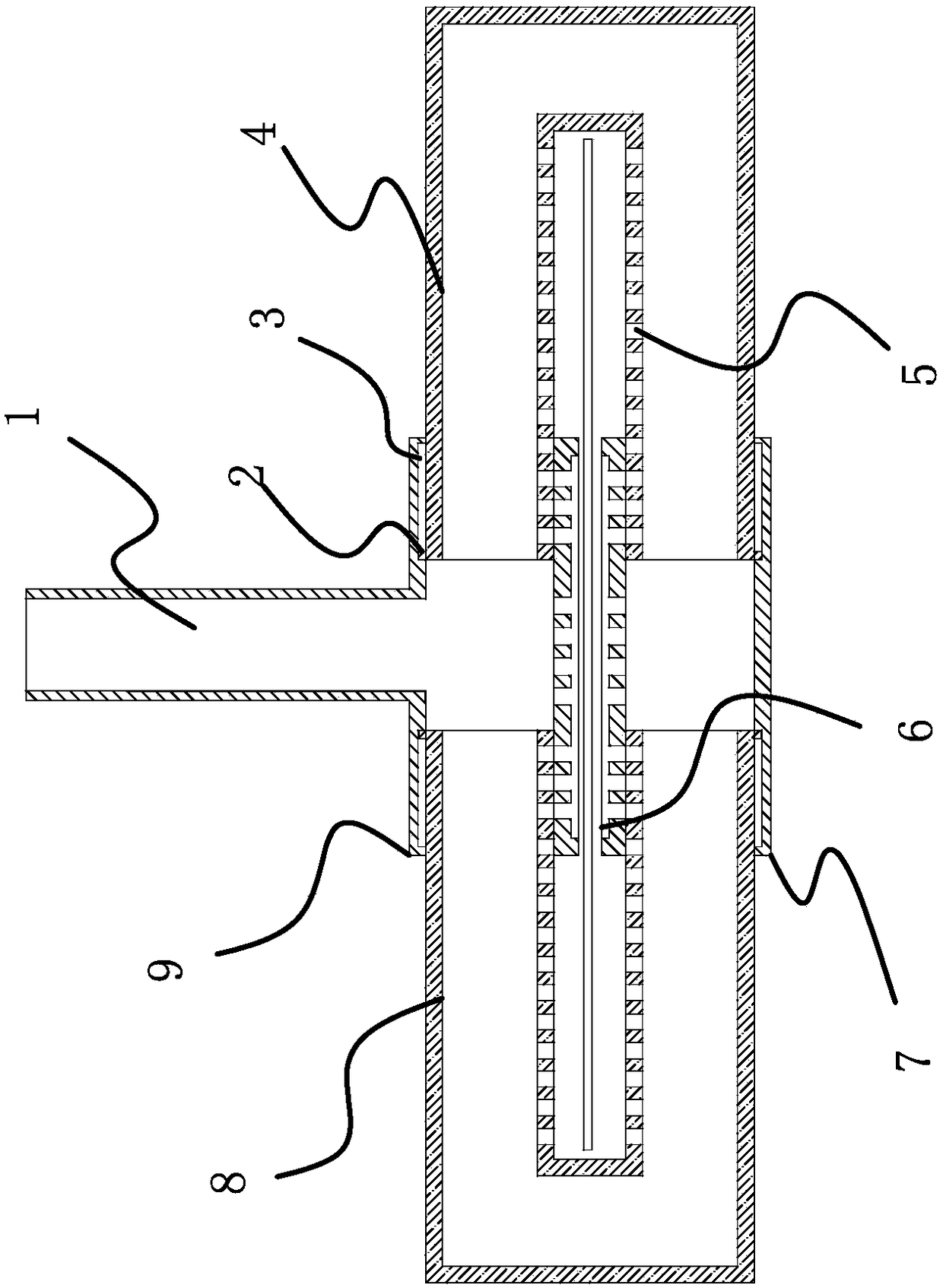

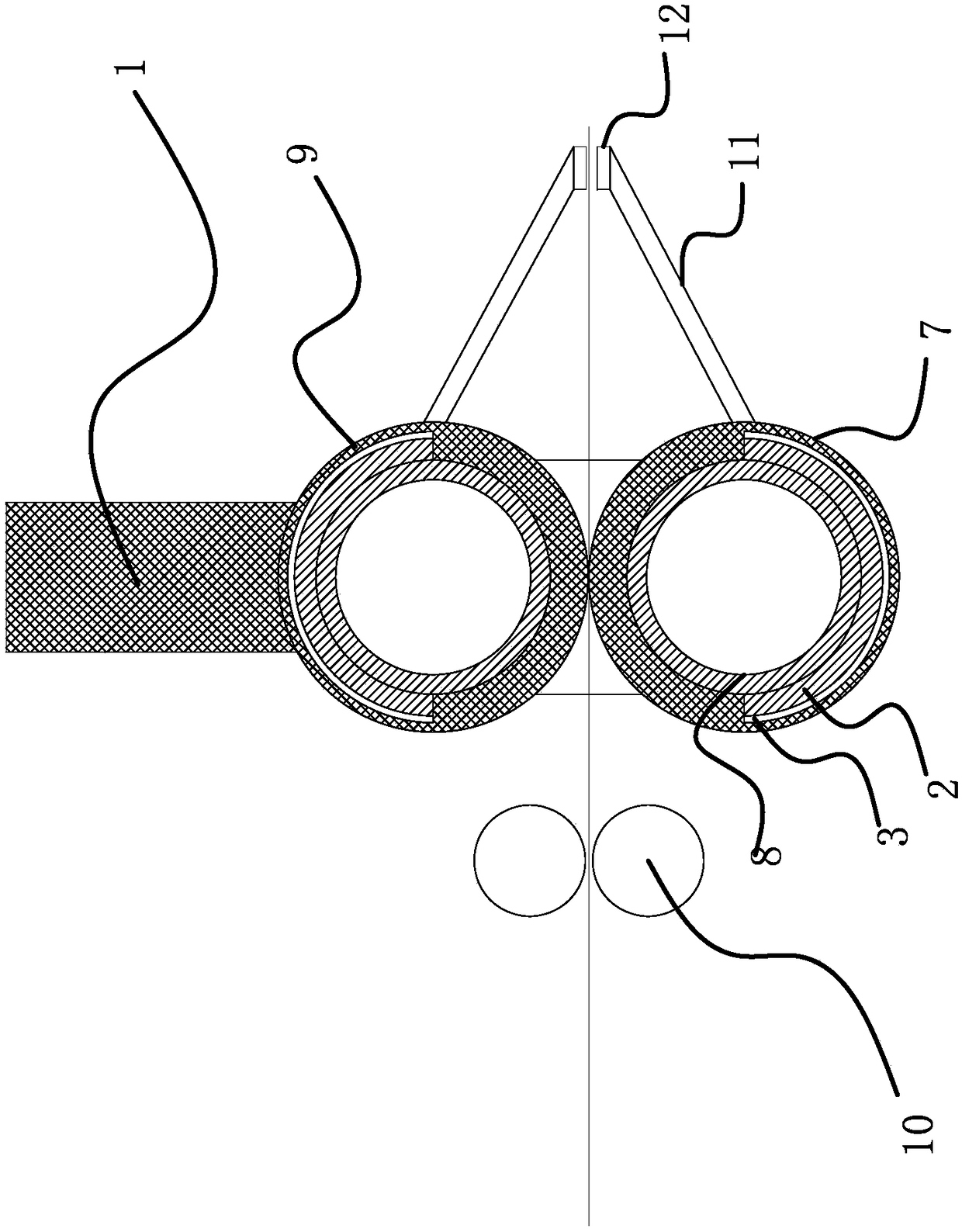

[0016] Such as Figure 1-2 Shown, the technical scheme of the present invention is the die head of a kind of effect coating machine, and it comprises feeding channel 1, the first middle pipe 9, the second middle pipe 7, the first concave pipe 8 that the section is circular and The second concave pipe 4 is characterized in that the sections of the first intermediate pipe 9 and the second intermediate pipe 7 are circular and arranged symmetrically up and down, and the two ends of the first concave pipe 8 are inserted into the first intermediate pipe 9 and one end of the second intermediate pipe 7, the second concave pipe 4 two ends are inserted into the first intermediate pipe 9 and the other end of the second intermediate pipe 7, the first concave pipe 8 and the second concave pipe 4 can be in the first middle Pipeline 9, the second middle pipe 7 lateral movement, the first middle pipe 9, the second middle pipe 7, the first concave pipe 8 and the second concave pipe 4 form a sq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com