Biomass material carbonization treatment method

A biomass material and carbonization treatment technology, which is applied in the direction of biofuel, special dry distillation, petroleum industry, etc., can solve the problem of high cost of carbonized biomass raw materials, achieve high biomass utilization rate, good effect, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

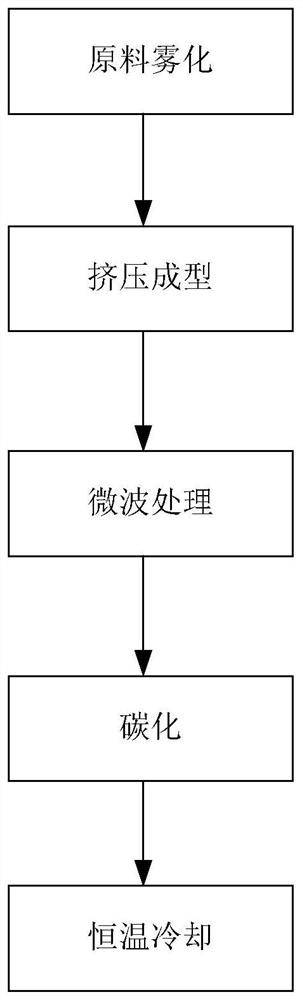

[0019] The invention provides a method for carbonizing biomass materials, comprising the following steps:

[0020] The first step is to crush the straw and atomize it to keep the water content at 3%-5% of the mass fraction;

[0021] The second step is to extrude the atomized straw and form a ball with a diameter of 30-55mm;

[0022] The third step is to microwave the above-mentioned balls to make the average temperature not lower than 45°C;

[0023] The fourth step is to put the processed pellets into the carbonization furnace for carbonization;

[0024] The fifth step is to maintain the stability of the carbonized pellets at 60-120°C under anaerobic conditions for 15-25 minutes; during this process, calcium carbonate powder is sprayed.

[0025] Preferably, wherein, in the fourth step, the carbonization condition is at 420-540° C., and the residence time is 30-40 minutes.

[0026] In the carbonization treatment method for biomass materials in this embodiment, in the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com