A new type of air storage tube device and ballast hopper car

A funnel car and air storage technology, which is applied in the field of railway freight cars, can solve the problems of difficult maintenance of transmission accessories such as two-way air cylinders, difficult operation of ballast unloading flow control devices, volume and self-heaviness of air storage cylinders, etc., and achieves diversified installation methods , Improve the safety of use and application, and the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062]Preferred embodiments of the present invention will be described in more detail below. Although preferred embodiments of the present invention are described below, it should be understood that the present invention can be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

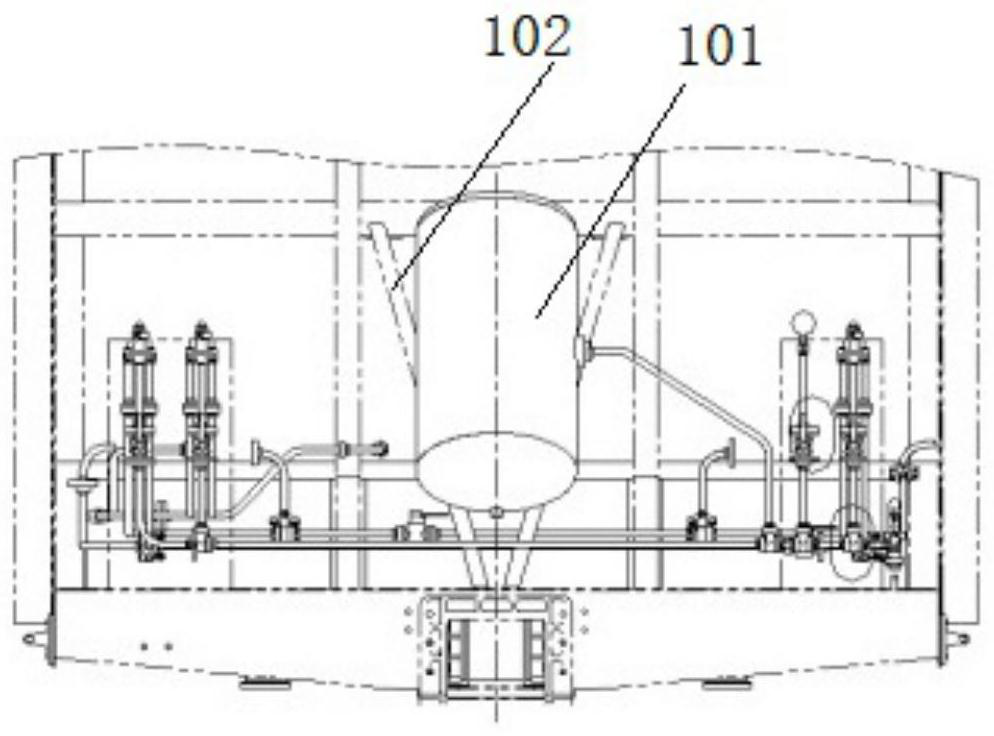

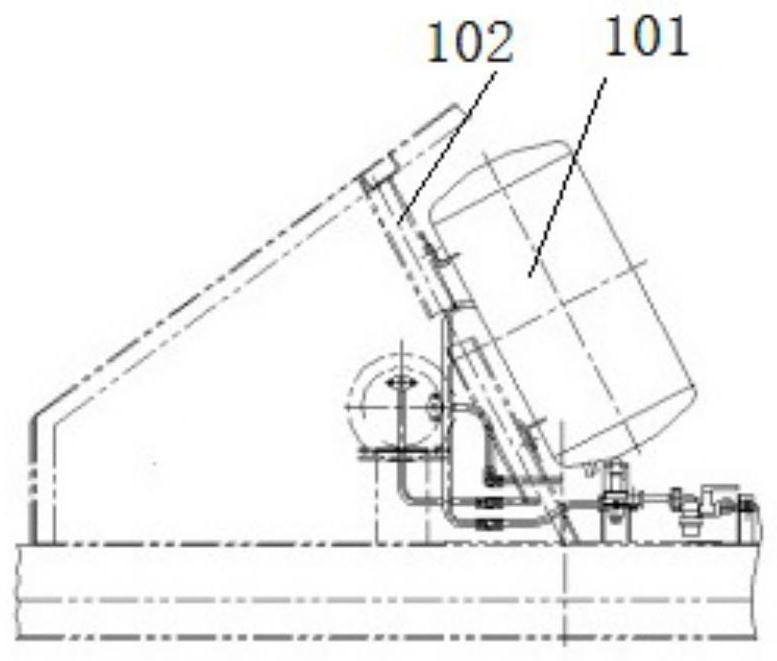

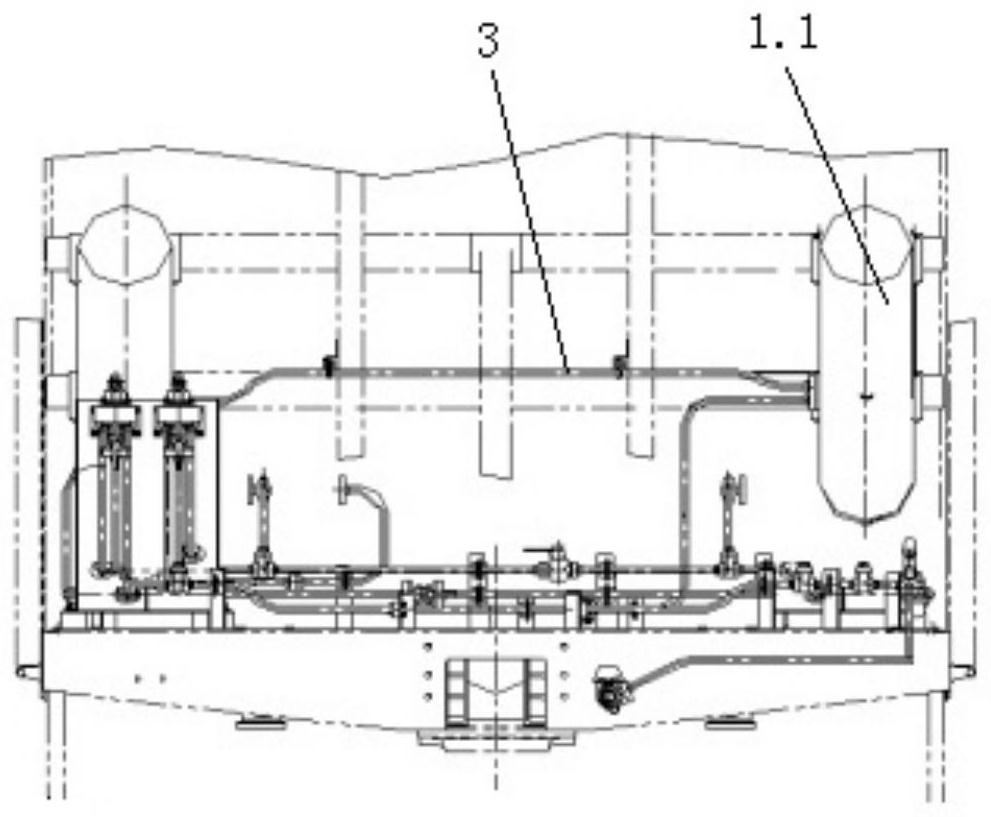

[0063] image 3 A structural schematic diagram showing a front view of a novel air storage device according to an embodiment of the present invention; Figure 4 It shows a structural schematic diagram of a left view of a novel air storage cylinder device according to an embodiment of the present invention; Figure 5 shows a novel air storage tube device according to an embodiment of the present invention Figure 4 Enlarged view of A.

[0064] Such as Figure 3-5 As shown, a new type of air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com