A quartz processing boiling cleaning device

A quartz and boiling tank technology, which is applied in the directions of drying gas arrangement, lighting and heating equipment, cleaning method using liquid, etc. and other problems to achieve the effect of improving boiling yield, reducing boiling time, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

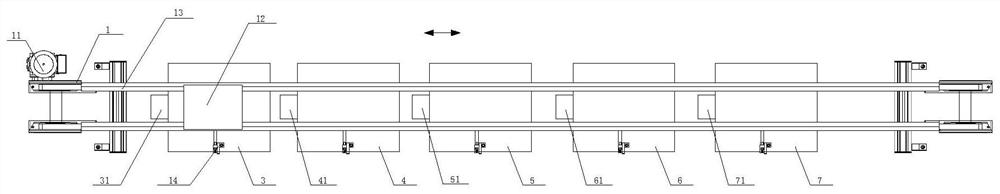

[0020] refer to Figure 1 to Figure 5 , the present embodiment provides a quartz processing boiling cleaning device, including a frame 1, a boiling tank 4, an electric push rod 2, a PLC control device, a slide plate 12, a degreasing tank 3, an ultrasonic cleaning tank 5, a moisturizing tank 6 and a drying tank. Dry tank 7, driving device 11, transmission mechanism 13 connected with driving device 11 are installed on the frame 1, material basket 21 is hung on the lower end of the electric push rod 2, guide rails and degreasing tank 3, boiling tank are provided on the frame 1 4. The ultrasonic cleaning tank 5, the moisturizing tank 6 and the drying tank 7 have corresponding sensor switches 14, the slide plate 12 is connected with the transmission mechanism 13 and moves horizontally along the guide rail under the action of the transmission mechanism 13, and the electric push rod 2 is installed on the slide plate 12 At the bottom, degreasing tank 3, boiling tank 4, ultrasonic clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com