Constant pressure pressing device and automatic kneading machine with constant pressure pressing device

A technology of pressurizing device and kneading machine, which is applied in the direction of fluid pressure control, non-electric variable control, sustainable manufacturing/processing, etc. The effect of increasing the amount of kneading, improving the kneading efficiency, and reducing the kneading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

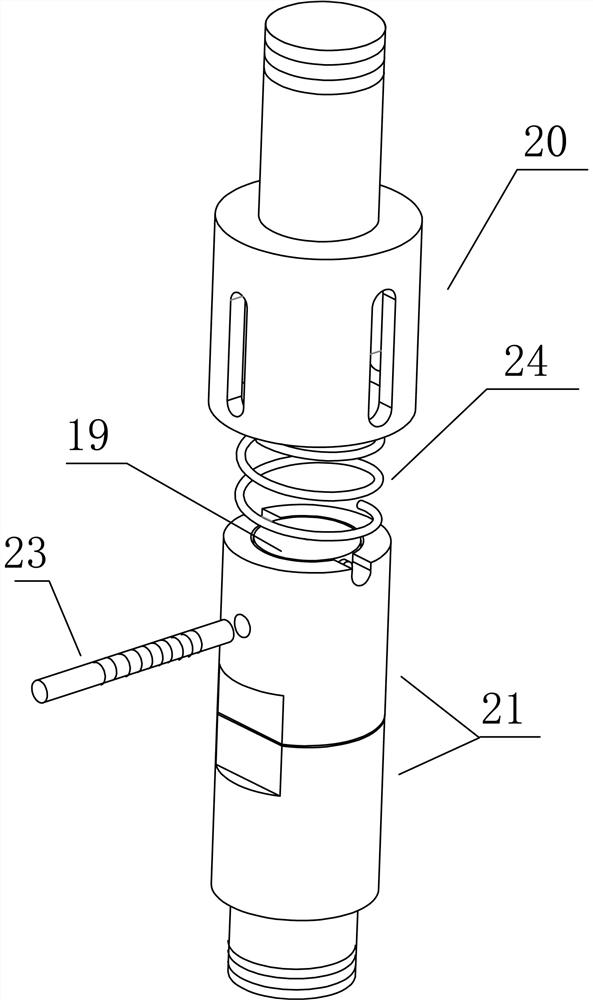

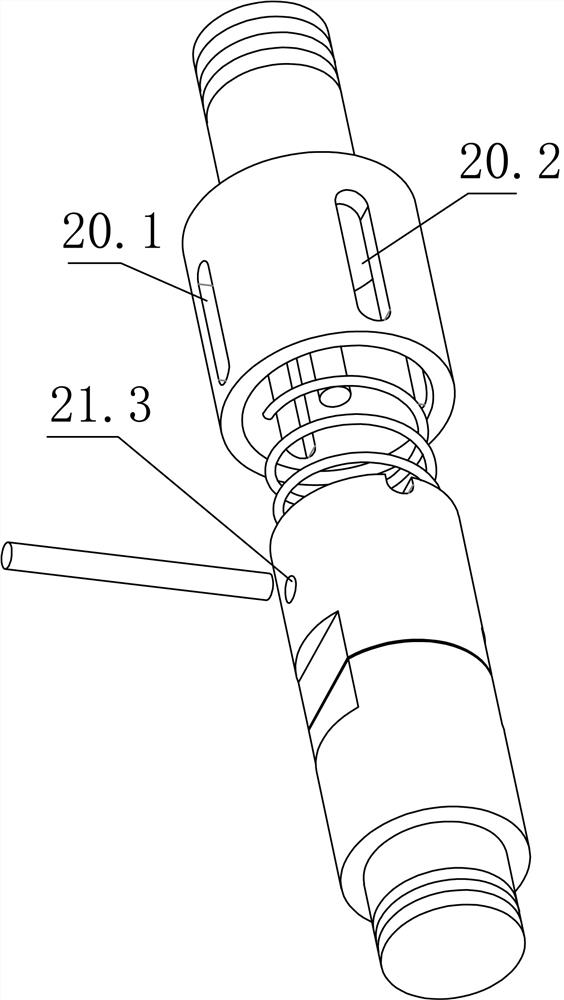

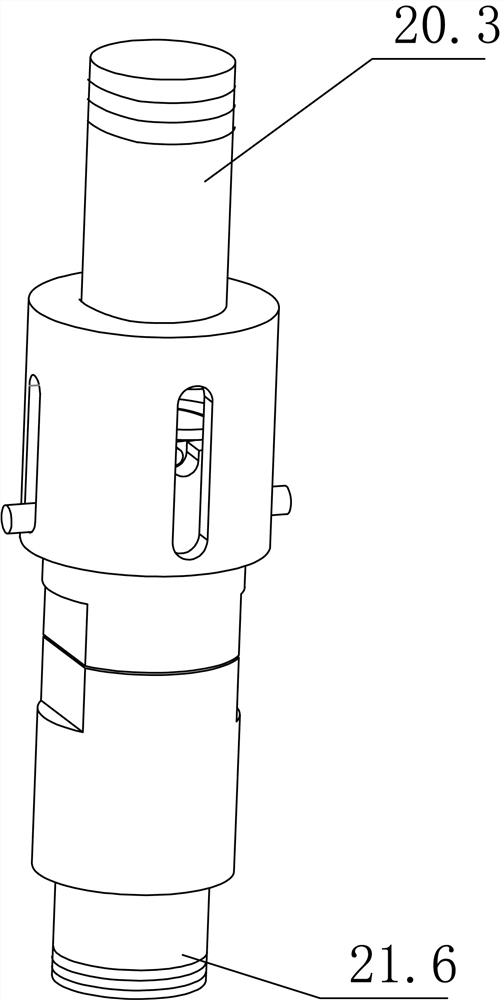

[0038] The preferred solution is Figure 1 to Figure 6 As shown, a constant pressure pressing device includes a pressure sensor 19, the pressure sensor 19 is installed between the upper connecting piece 20 and the lower connecting piece 21, and the upper connecting piece 20 and the lower connecting piece 21 are slidably connected, The upper connecting piece 20 is driven to move up and down by the gland lifting device 22, and the lower connecting piece 21 is used for connecting with the gland.

[0039]The gland lifting device 22 is preferably an electric push rod, and its model can be an XTL100 DC electric push rod. The motor of the electric push rod is a servo motor, and the servo controller is the main control device of the local solution. The pressure sensor 19 can be a button-type pressure sensor. The pressure sensor 19 converts the pressure signal into an analog signal of 4-20mA. The servo controller controls the action of the electric push rod according to the analog sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com