Reed harvesting and bundling machine

A technology of binding machine and binding mechanism, which is applied in the direction of harvesters, individual binding machines, cutters, etc., can solve the problems that harvesting machines are difficult to reach, reduce efficiency, and cannot complete reeds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

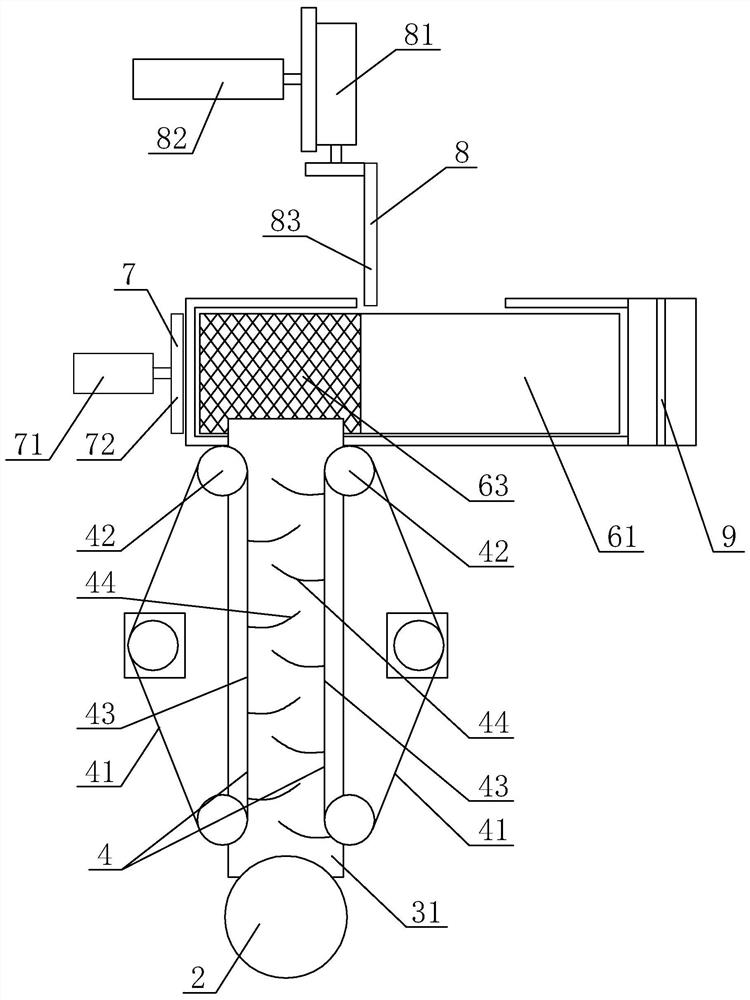

[0022] Such as figure 1 , 2 Shown in , 3, 4, 5, 6, be the specific embodiment of reed harvesting binding machine of the present invention, this ramie harvester comprises car body 1 and the stalk cutter 2 that is arranged on car body 1 front, The lower part is provided with rollers 11, the rear portion of the car body 1 is provided with a handle 12 for the user to push, and the car body 1 is also provided with a feeding passage 3, a feeding mechanism 4, a cutting knife 5, a discharge passage 6, and an upper pushing material. Mechanism 7, lower pushing mechanism 8 and binding mechanism 9, the rear of stalk cutting knife 2 is provided with feeding passage 3, the bottom of this feeding passage 3 is provided with first support plate 31, and feeding mechanism 4 is arranged on the both sides of feeding passage 3 , the feeding mechanism 4 clamps the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com