A kind of porous carbon electrode material supporting metal oxide and preparation method thereof

A porous carbon electrode, metal-loaded technology, applied in chemical instruments and methods, carbon compounds, non-metallic elements, etc., can solve the problems of low energy density of activated carbon-based supercapacitors, affecting the performance of electrode materials, limited specific capacitance, etc., and achieve stability. Cycling performance, increasing storage, increasing the effect of specific capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A. Place 8g of activated carbon powder in a hydrochloric acid solution with a concentration of 10% by volume, and the mass-volume ratio kg / L of activated carbon to hydrochloric acid solution is 1:200; and heat under reflux at 25-50°C for 5h, and filter the precipitate obtained by suction. drying;

[0030] B, the material obtained in step A is washed with deionized water at 25°C for 12h, and the mass-volume ratio kg / L of the material and deionized water is 1:500; the precipitate obtained by suction filtration is dried and repeated 3 times to obtain activated carbon material;

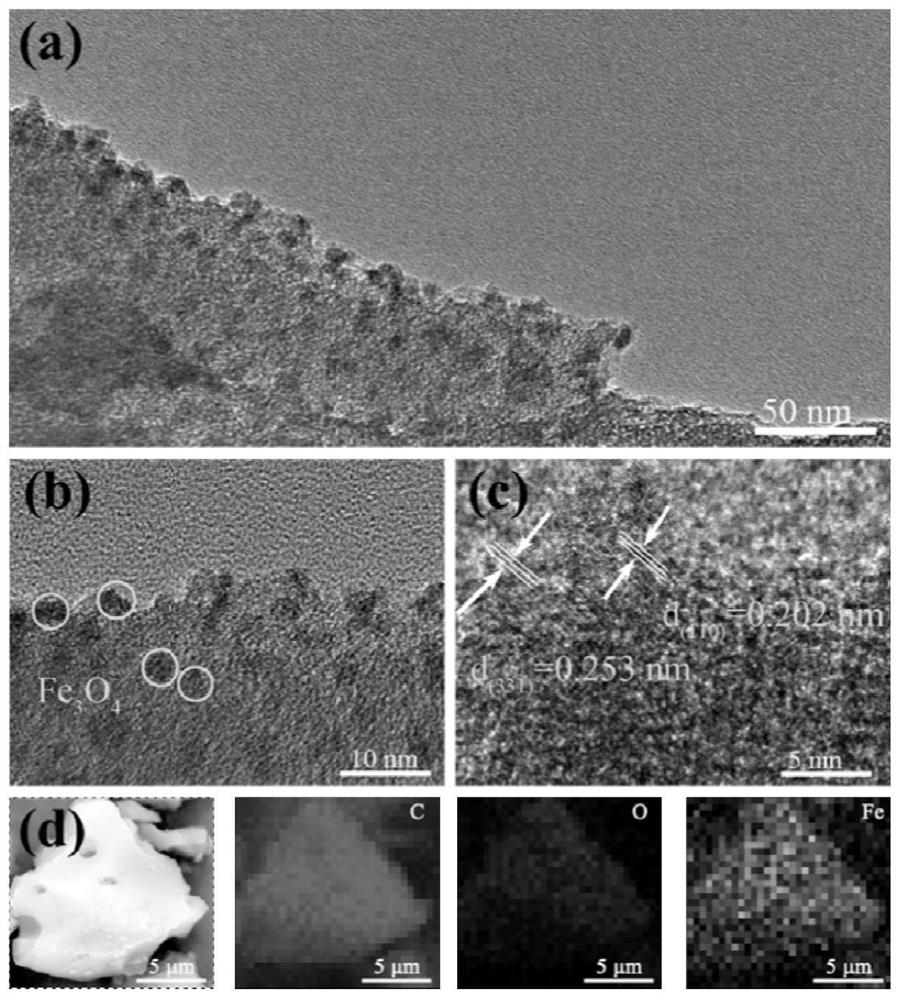

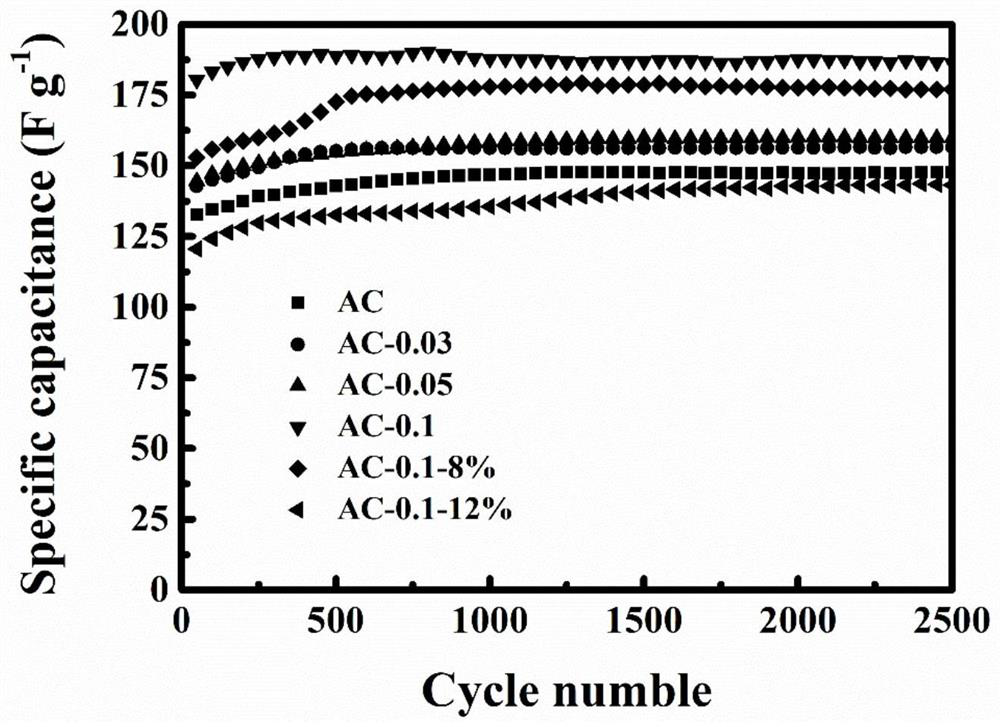

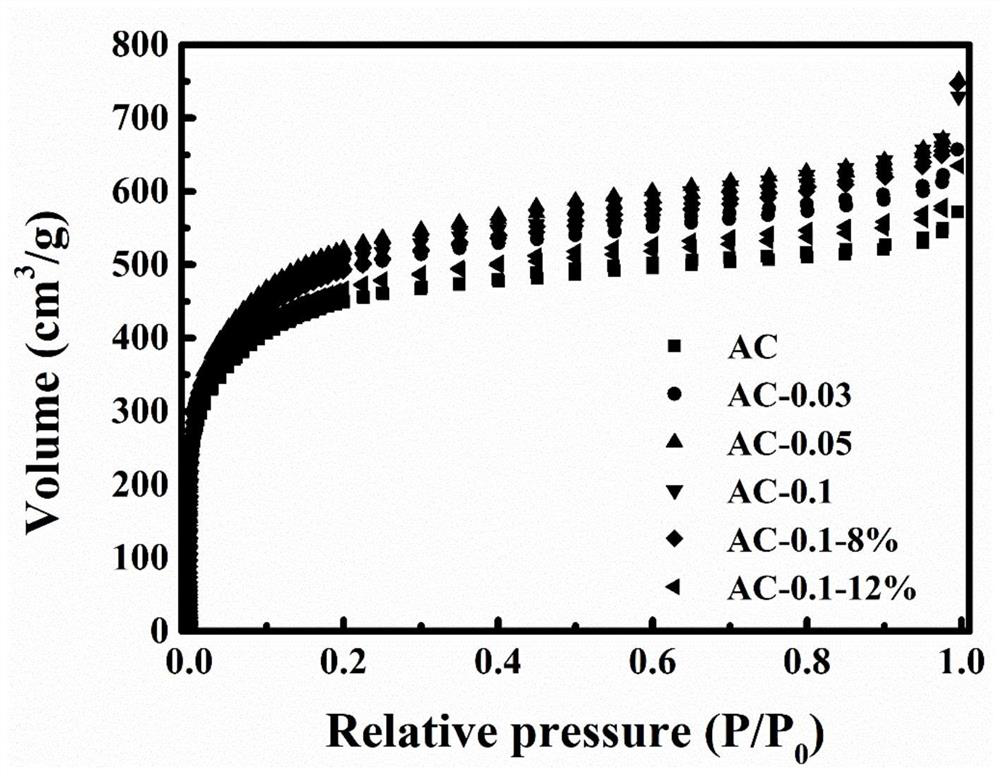

[0031] C, the activated carbon material obtained in step B is placed in a suction filter bottle, and the 0.03M FeCl is mixed with a burette 3 10ml of the aqueous solution was slowly dropped into a suction filter bottle under vacuum and kept shaking to obtain a mixture in a paste state, then ultrasonically immersed at 60°C for 1h, then dried at 120°C under vacuum for 5h, and finally placed in a tub...

Embodiment 2

[0034] A. Place 8g of activated carbon powder in a hydrochloric acid solution with a concentration of 10% by volume, and the mass-volume ratio kg / L of activated carbon to hydrochloric acid solution is 1:200; and heat under reflux at 25-50°C for 5h, and filter the precipitate obtained by suction. drying;

[0035] B, the material obtained in step A is washed with deionized water at 25°C for 12h, and the mass-volume ratio kg / L of the material and deionized water is 1:500; the precipitate obtained by suction filtration is dried and repeated 3 times to obtain activated carbon material;

[0036] C, the activated carbon material obtained in step B is placed in a suction filter bottle, and 0.05M FeCl is mixed with a burette 3 10ml of the aqueous solution was slowly dropped into a suction filter bottle under vacuum and kept shaking to obtain a mixture in a paste state, then ultrasonically immersed at 60°C for 1h, then dried at 120°C under vacuum for 5h, and finally placed in a tube fu...

Embodiment 3

[0039] A. Place 8g of activated carbon powder in a hydrochloric acid solution with a concentration of 10% by volume, and the mass-volume ratio kg / L of activated carbon to hydrochloric acid solution is 1:200; and heat under reflux at 25-50°C for 5h, and filter the precipitate obtained by suction. drying;

[0040]B, the material obtained in step A is washed with deionized water at 25°C for 12h, and the mass-volume ratio kg / L of the material and deionized water is 1:500; the precipitate obtained by suction filtration is dried and repeated 3 times to obtain activated carbon material;

[0041] C, the activated carbon material obtained in step B is placed in a suction filter bottle, and 0.1M FeCl is mixed with a burette 3 10ml of the aqueous solution was slowly dropped into a suction filter bottle under vacuum and kept shaking to obtain a mixture in a paste state, then ultrasonically immersed at 60°C for 1h, then dried at 120°C under vacuum for 5h, and finally placed in a tube furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com