Reverse rotational flow air field-division ventilation and dust control method and system for fully-mechanized excavation face

A fully-mechanized excavation face and swirling air technology, applied in the field of reverse swirl air sub-area ventilation and dust control methods and systems for fully-mechanized excavation faces, can solve the problem of popularization and use of difficult mechanized excavation faces, heavy weight of wall-attached air ducts, and high-concentration dust pollution and other problems to achieve the effect of alleviating the gas accumulation problem, reducing the risk of gas explosion, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention provides a method and system for subregional ventilation and dust control of reverse swirling wind in fully mechanized excavation face. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

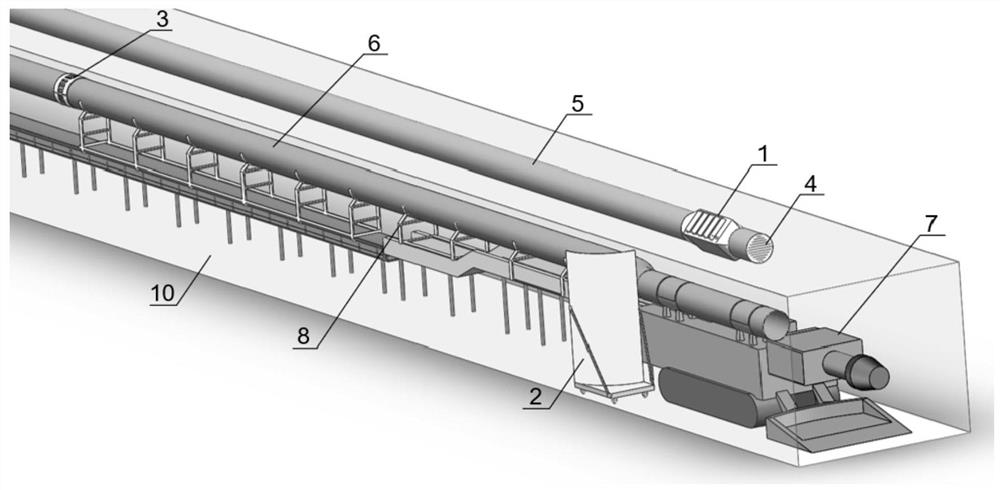

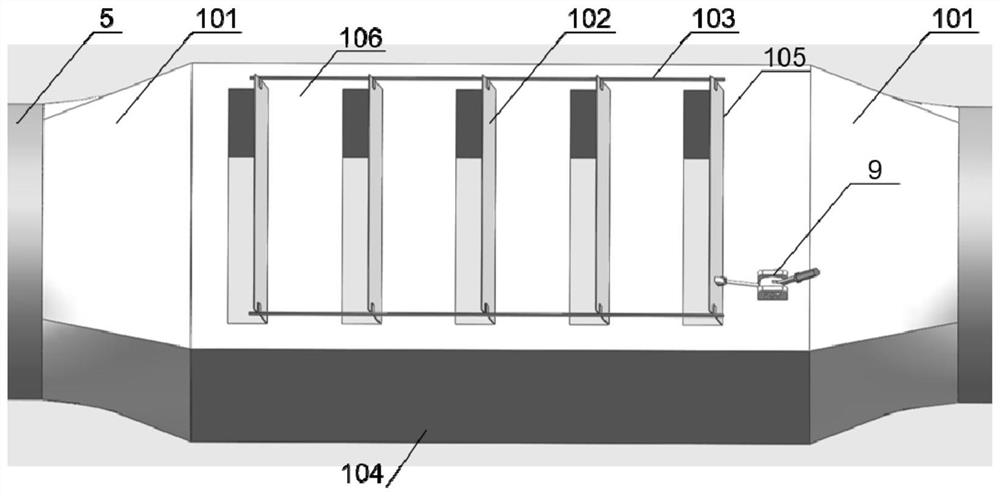

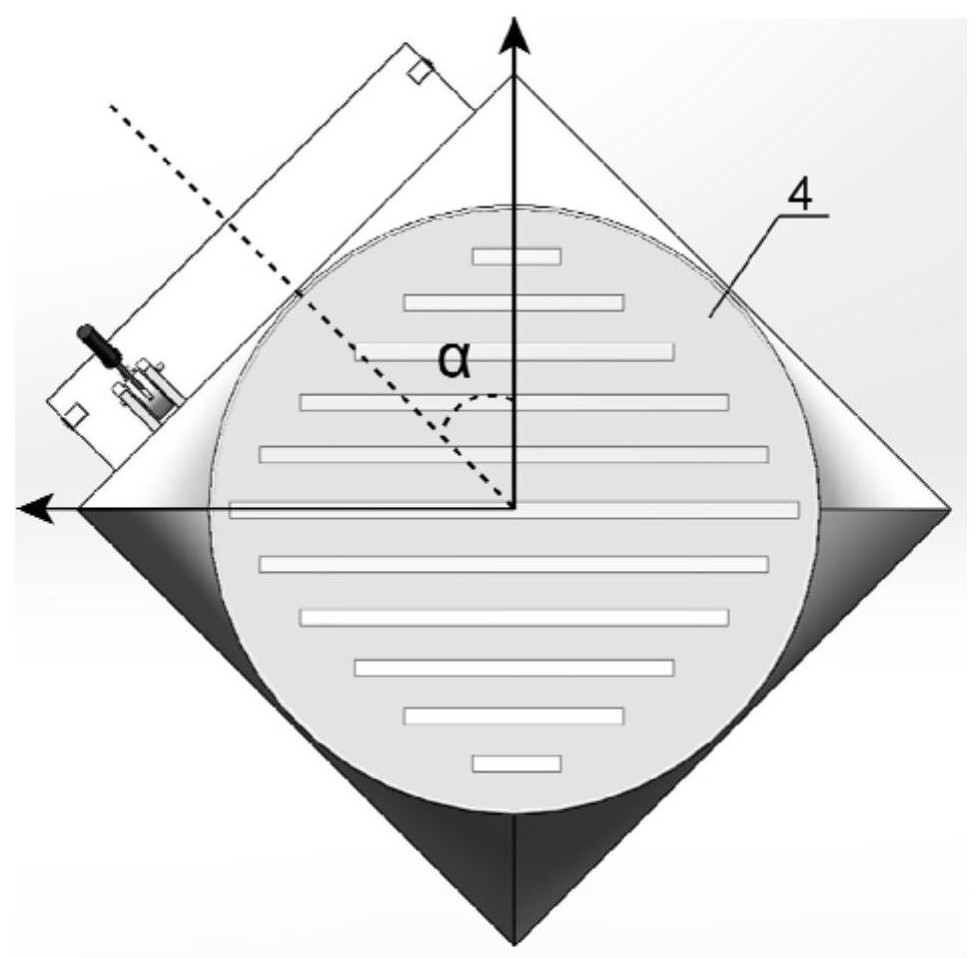

[0034]The invention provides a method for sub-regional ventilation and dust control of reverse swirling wind in a fully mechanized excavation face, such as figure 1 , Figure 9 and Figure 10 As shown, the fresh air flow transported by the compressed air duct 5 arranged in the fully mechanized excavation face is ejected separately from the radial air injection port 1 and the axial air injection port according to a certain proportion, and an axial air cover 4 is arranged on the axial air injection port. In order to control the air outlet ratio; an exhaust duct 6 is arranged in the fully mechanized excavation surface on the other side of the air pressure du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com