Mung bean protein peptide preparation method

A mung bean protein and protein technology, which is applied in the field of protein peptide processing, can solve the problems of poor stability of peptide content, unsatisfactory peptide activity, and low protein conversion rate, so as to reduce energy consumption, improve physical and chemical indicators and functional indicators, and improve effective The effect of ingredient content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

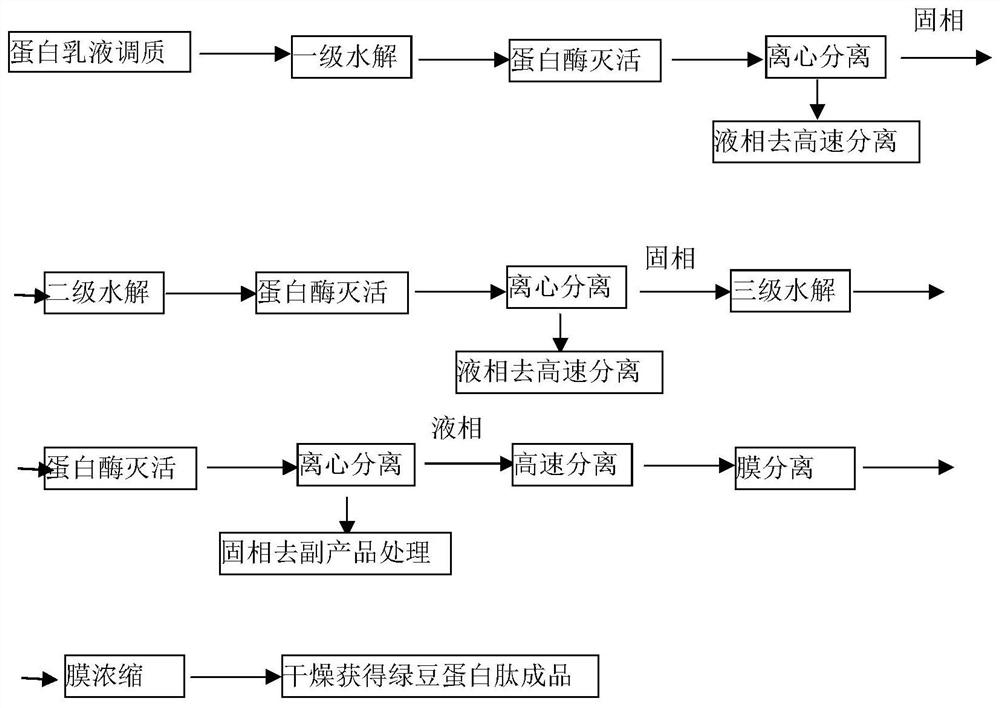

[0028] A method for preparing mung bean protein peptide, comprising the steps of:

[0029] (1) Conditioning protein milk with a protein concentration of 7.7%, adjusting the pH value to 7.2, killing miscellaneous bacteria, and fully denaturing the protein;

[0030] (2) Adjust the temperature to 54.4°C, add neutral protease according to 0.35% of the substrate, perform primary hydrolysis under the condition of mechanical stirring and sufficient mixing, and keep the hydrolysis for 4 hours;

[0031] (3) heating to 85°C and incubating for 15 minutes to inactivate the protease;

[0032] (4) Adopting a decanter centrifuge to centrifugally separate the first-stage hydrolyzed mixture to separate the water-soluble hydrolyzate from the water-insoluble, and the separated liquid phase is transferred to a subsequent treatment process;

[0033] (5) adding water to the solid-phase substance separated in step (4) and fully stirring and mixing, carrying out secondary hydrolysis according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com