Preparation method of copper alginate loaded laccase and mediator ABTS composite biocatalyst

A biocatalyst, copper alginate technology, applied in biochemical equipment and methods, chemical instruments and methods, fixed on/in organic carriers, etc., can solve the problem that the mediator ABTS cannot be recycled and unfavorable for the green development of the surrounding environment , can not effectively catalyze the substrate and other problems, and achieve the effect of good industrial application prospect, excellent catalytic activity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a copper alginate-supported laccase and a mediator ABTS composite biocatalyst, comprising the following steps:

[0031] S1. Dissolving sodium alginate powder in deionized water to prepare an aqueous solution of sodium alginate with a mass fraction of 1.5wt%-3wt%, and then performing ultrasonic treatment; wherein, the ultrasonic treatment is performed at a temperature of 40-50°C and a frequency of 100Hz. Ultrasonic treatment time is 10-20min;

[0032] S2, dissolving anhydrous copper sulfate in deionized water to prepare a copper sulfate solution of 0.1mol / L-0.2mol / L;

[0033] S3. Adding the mediator substance ABTS with a concentration of 0.1mmol / L-5mmol / L to the sodium alginate aqueous solution obtained in step S1 to obtain solution A, and then performing ultrasonic treatment;

[0034] S4. Add laccase with a concentration of 2.5g / L-10g / L to the sodium alginate aqueous solution obtained in step S1 to obtain solution B, and th...

Embodiment 1

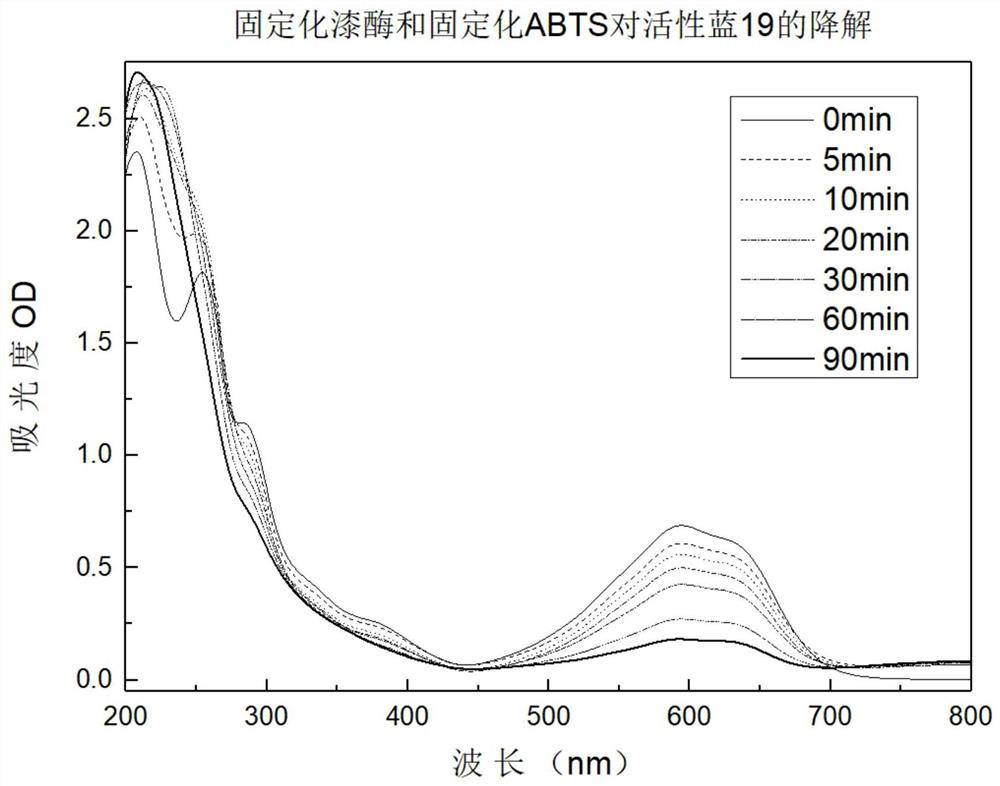

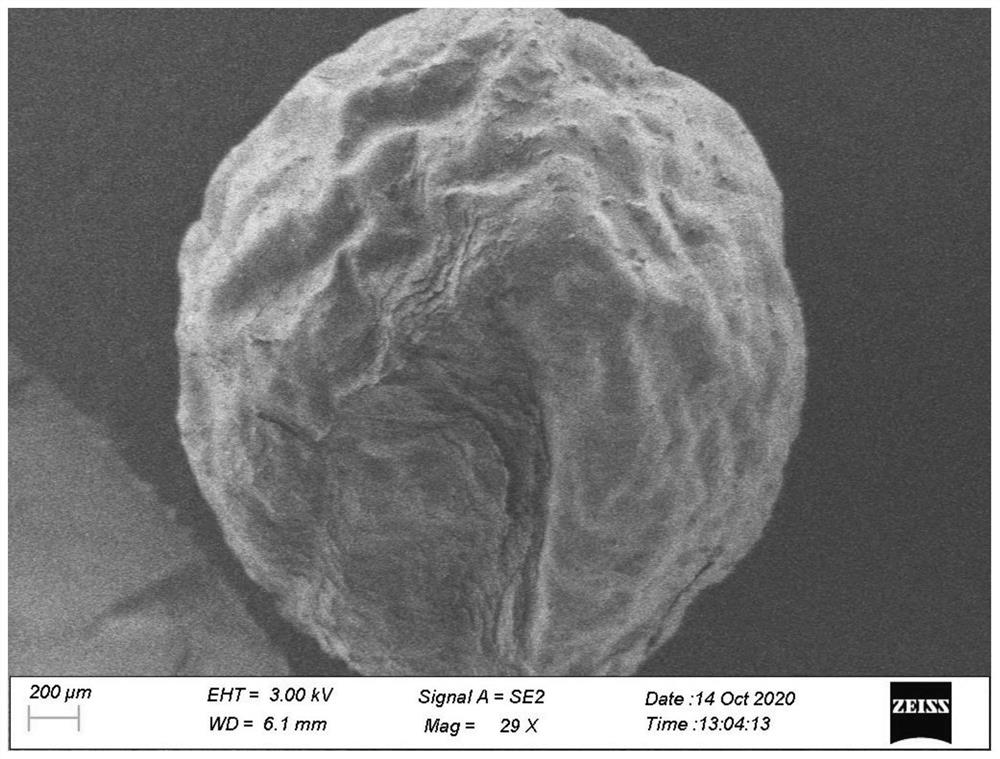

[0038] (1) Preparation of Alginate Copper Carrier Immobilized Mediator Substance ABTS

[0039] Add 2.5g of sodium alginate powder into 100mL of deionized water, stir vigorously at room temperature for about 30min until completely dissolved. Then, under the condition of a frequency of 100 Hz, it was ultrasonicated at room temperature for about 10 min to prepare a sodium alginate aqueous solution with a mass fraction of 2.5 wt%. Add the mediator substance ABTS (5mmol / L) to the above solution, and then, under the condition of frequency 50Hz, sonicate at room temperature for about 10min to obtain a uniform solution. The above solution was added dropwise into 100 mL of copper sulfate solution (0.1 mol / L), and stirred until the reaction was completed to obtain immobilized mediator substance ABTS beads.

[0040] (2) Preparation of copper alginate carrier immobilized laccase

[0041] Add 2.5g of sodium alginate powder into 100mL of deionized water, and stir vigorously at room temper...

Embodiment 2

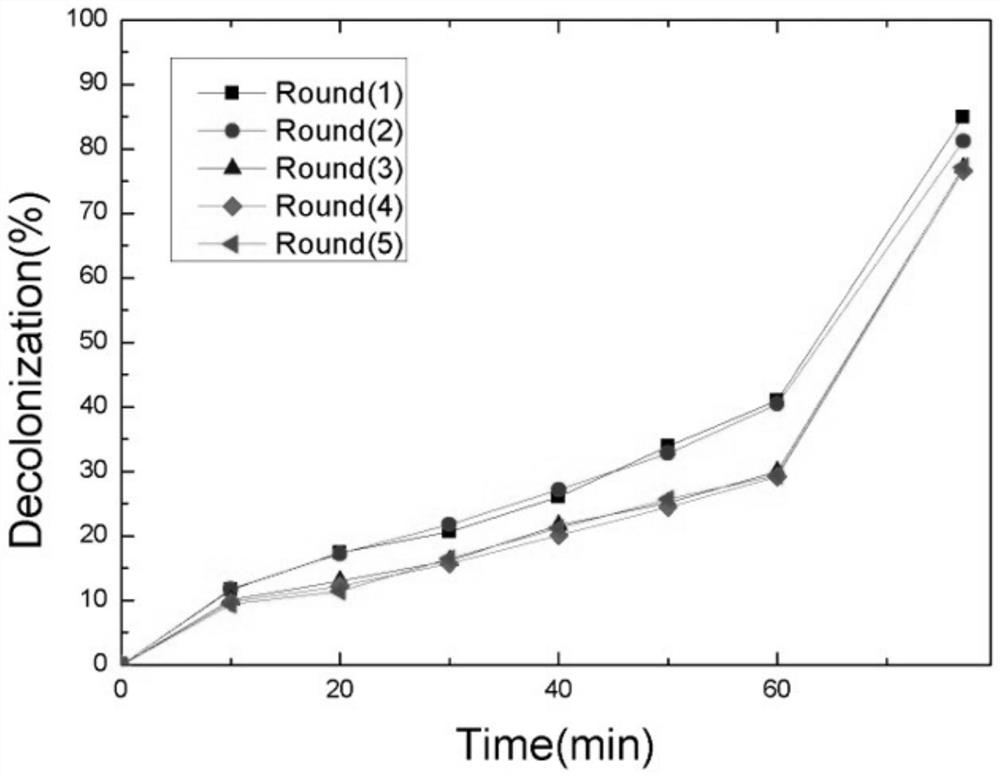

[0043] Enzyme activity assay of immobilized laccase

[0044] Mix the buffer with ABTS, take 5g of copper alginate carrier to immobilize laccase, add 10mL of ABTS (0.1mmol·L-1) and 40mL of acetic acid-sodium acetate buffer solution (pH=4.6), stop in ice bath after 20min of reaction, The absorbance at 420 nm was measured after the supernatant was filtered.

[0045] The formula for calculating the enzyme activity of immobilized laccase is as follows:

[0046] U / mL=((ΔAV / εDt) / V0)×105.

[0047] ΔA=1.43 U=U / L=99.39 μmol / mg / min 99.39 / 422.23=23.54%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com