Preparation method of lithium ion battery negative electrode material high-entropy oxide

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, chemical instruments and methods, negative electrodes, etc., can solve the problems of high production energy consumption, low specific capacity, and difficulty in large-scale production, and achieve low cost and high ratio The effect of capacity and Coulombic efficiency stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Take 10 g Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 co 0.2 High-entropy alloy ingots are degreased, polished and derusted, washed with distilled water, washed twice with alcohol solution, and dried in vacuum at 60°C for 20 hours;

[0023] (2) For high entropy alloy Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 co 0.2 Melting, gas atomization granulation under argon atmosphere, and then sieving to select alloy powder with a particle size of <53 μm;

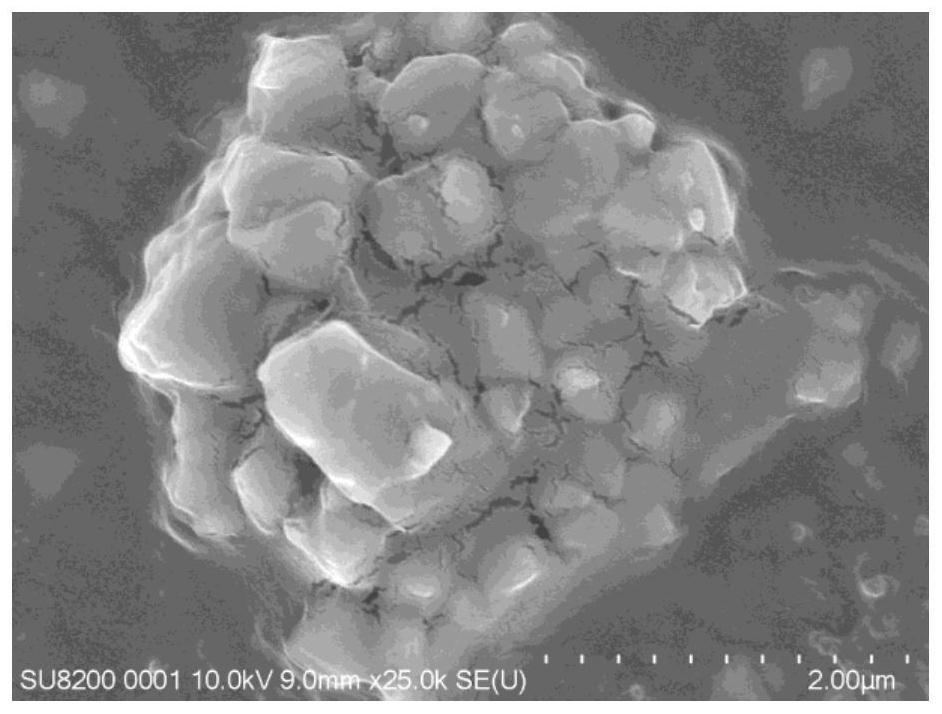

[0024] (3) Weigh 200 mg of high-entropy alloy powder, heat it up to 1000 °C at a rate of 5 °C / min, keep it for 24 h, and its oxygen partial pressure is 80 kPa. After cooling, (Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 co 0.2 ) 3 o 4 High entropy oxides.

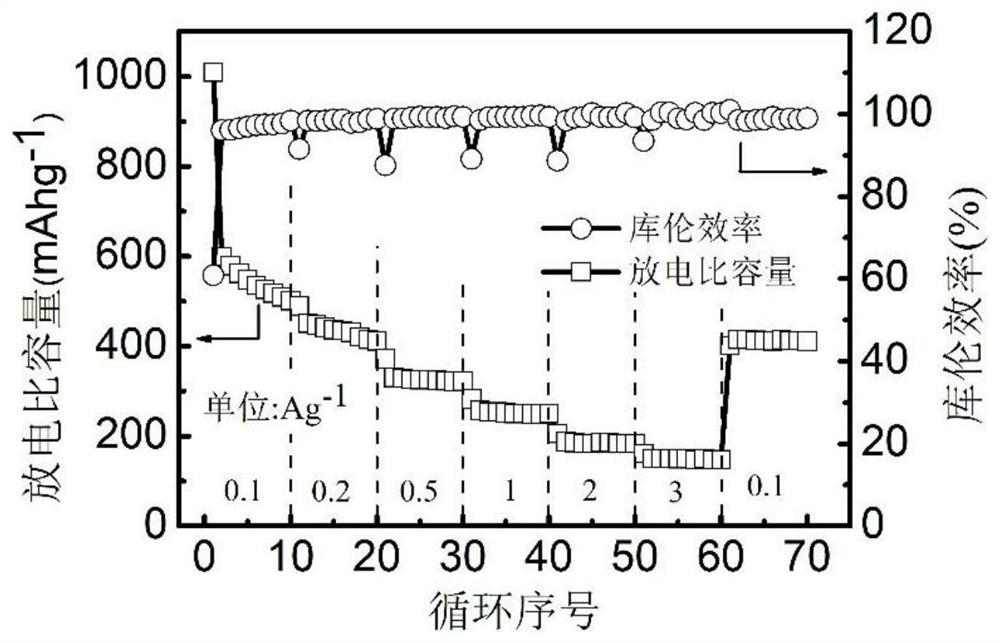

[0025] Such as figure 1 As shown, the lithium battery negative electrode material (Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 co 0.2 )3 o 4 The peak of the high-entropy oxide on XRD is basically consistent with the peak of the standard product, and there is no impurity peak, so it can be determined that the...

Embodiment 2

[0032] (1) Take 8 g Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 co 0.2 High-entropy alloy ingots are degreased, polished and derusted, washed with distilled water, washed twice with alcohol solution, and dried in vacuum at 40°C for 72 hours;

[0033] (2) For high entropy alloy Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 co 0.2 Melting, gas atomization granulation under argon atmosphere, and then sieving to select alloy powder with a particle size of <30 μm;

[0034] (3) Weigh 2000 mg of high-entropy alloy powder, raise the temperature to 800 °C at a rate of 10 °C / min, keep it for 48 h, and its oxygen partial pressure is 80 kPa. After cooling, (Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 co 0.2 ) 3 o 4 High entropy oxides.

[0035] The obtained lithium battery negative electrode material (Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 co 0.2 ) 3 o 4 The peaks of high-entropy oxides on XRD are basically the same as those of standard products, and there are no impurity peaks. It can be determined that the obtained material...

Embodiment 3

[0042] (1) Take 15 g Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 co 0.2 High-entropy alloy ingots are degreased, polished and derusted, washed with distilled water, washed twice with alcohol solution, and dried in vacuum at 90°C for 12 hours;

[0043] (2) For high entropy alloy Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 co 0.2 Carry out melting, carry out gas atomization granulation under the mixed gas atmosphere of argon and nitrogen, and then sieve, select the alloy powder with particle size <230 μm;

[0044] (3) Weigh 1000 mg of high-entropy alloy powder, raise the temperature to 1100 ℃ at a rate of 0.1 ℃ / min, keep it for 8 hours, and its oxygen partial pressure is 21.278 kPa. After cooling, (Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 co 0.2 ) 3 o 4 High entropy oxides.

[0045] The obtained lithium battery negative electrode material (Cr 0.2 Fe 0.2 mn 0.2 Ni 0.2 co 0.2 ) 3 o 4 The peaks of high-entropy oxides on XRD are basically the same as those of standard products, and there are no impurity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com