Lifting appliance swing preventing system for crossing type double-trolley quay crane

A technology of traversing, vehicle-mounted quayside cranes, applied in the directions of load suspension components, transportation and packaging, etc., can solve problems affecting the loading and unloading efficiency of quayside cranes, high initial investment and maintenance costs of control equipment, and excessively frequent adjustment of trolley operation. Data and other issues, to achieve the effect of low initial investment and operation and maintenance costs, stable operation, and prevention of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

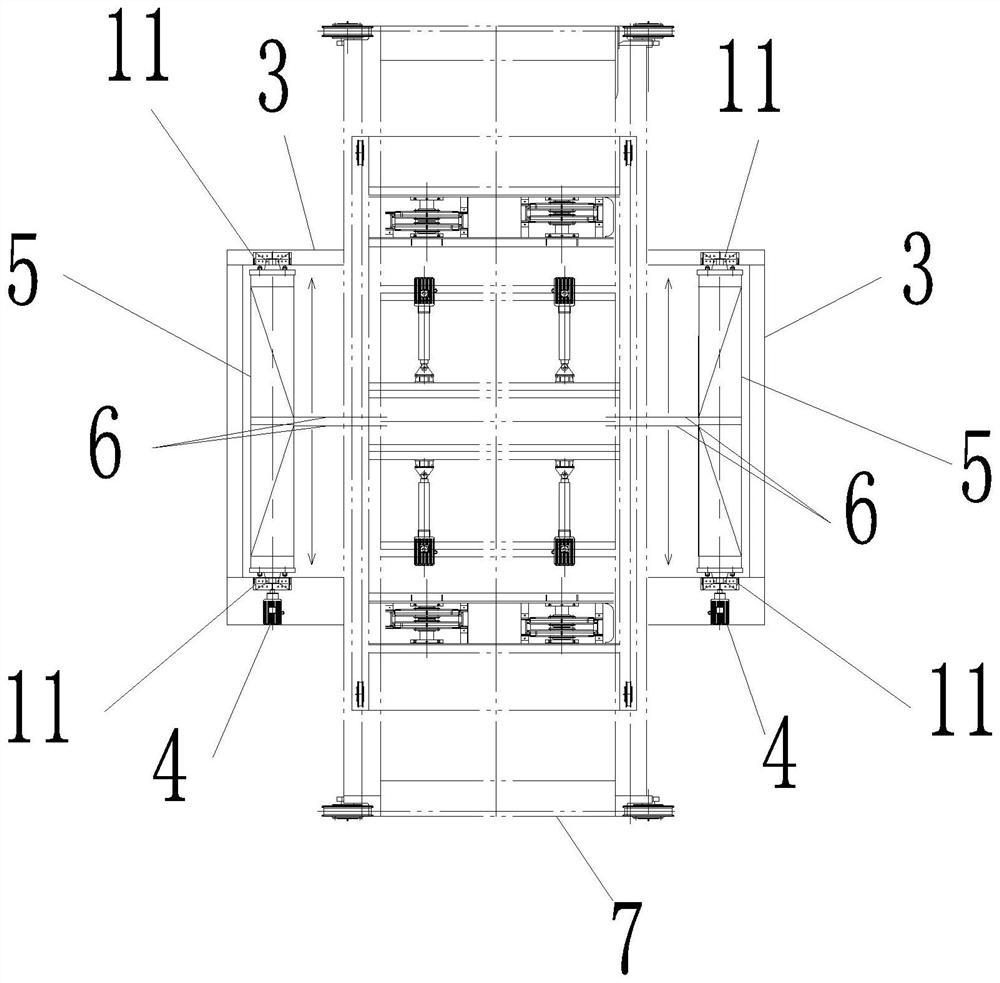

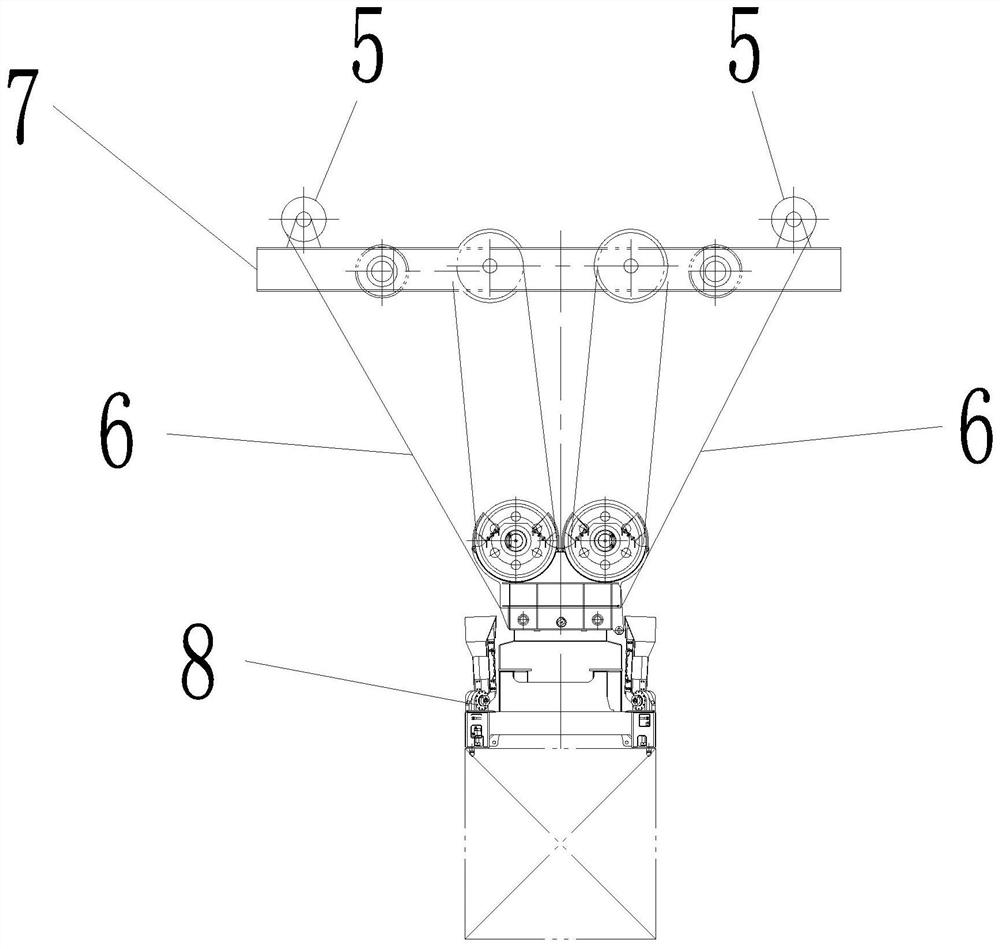

[0027] Embodiment 1 of the present invention: as Figure 7 As shown, a spreader anti-sway system for a through-type double-trolley quay crane includes an upper trolley spreader anti-sway device 1 and a lower trolley spreader anti-sway device 2 . like figure 1 and Figure 4 As shown, the anti-sway device 1 of the upper trolley spreader and the anti-sway device 2 of the lower trolley are similar in structure, and both include two underframes 3 , two torque motors 4 , two anti-sway reels 5 and anti-sway wire ropes 6 . The torque motor 4 and the anti-sway reel 5 are transmission-connected, and both the torque motor 4 and the anti-sway reel 5 are fixed on the chassis 3 , and the anti-sway wire rope 6 is wound on the anti-sway reel 5 . like figure 2 or image 3 As shown, the bottom frame 3 in the anti-sway device 1 of the upper trolley spreader is fixedly connected with the upper trolley 7, and the anti-sway wire rope 6 in the anti-sway device 1 of the upper trolley spreader is...

Embodiment 2

[0035] Embodiment 2 of the present invention: as Figure 7 As shown, a spreader anti-sway system for a through-type double-trolley quay crane includes an upper trolley spreader anti-sway device 1 and a lower trolley spreader anti-sway device 2 . like figure 1 and Figure 4 As shown, the anti-sway device 1 of the upper trolley spreader and the anti-sway device 2 of the lower trolley are similar in structure, and both include two underframes 3 , two torque motors 4 , two anti-sway reels 5 and anti-sway wire ropes 6 . The torque motor 4 and the anti-sway reel 5 are transmission-connected, and both the torque motor 4 and the anti-sway reel 5 are fixed on the chassis 3 , and the anti-sway wire rope 6 is wound on the anti-sway reel 5 . like figure 2 or image 3 As shown, the bottom frame 3 in the anti-sway device 1 of the upper trolley spreader is fixedly connected with the upper trolley 7, and the anti-sway wire rope 6 in the anti-sway device 1 of the upper trolley spreader is...

Embodiment 3

[0045] Embodiment 3 of the present invention: as Figure 7 As shown, a spreader anti-sway system for a through-type double-trolley quay crane includes an upper trolley spreader anti-sway device 1 and a lower trolley spreader anti-sway device 2 . like figure 1 and Figure 4 As shown, the anti-sway device 1 of the upper trolley spreader and the anti-sway device 2 of the lower trolley are similar in structure, and both include two underframes 3 , two torque motors 4 , two anti-sway reels 5 and anti-sway wire ropes 6 . The torque motor 4 and the anti-sway reel 5 are transmission-connected, and both the torque motor 4 and the anti-sway reel 5 are fixed on the chassis 3 , and the anti-sway wire rope 6 is wound on the anti-sway reel 5 . like figure 2 or image 3 As shown, the bottom frame 3 in the anti-sway device 1 of the upper trolley spreader is fixedly connected with the upper trolley 7, and the anti-sway wire rope 6 in the anti-sway device 1 of the upper trolley spreader is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com