Composite wheel for construction vehicle

A compound wheel and vehicle technology, applied in the field of compound wheels, can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

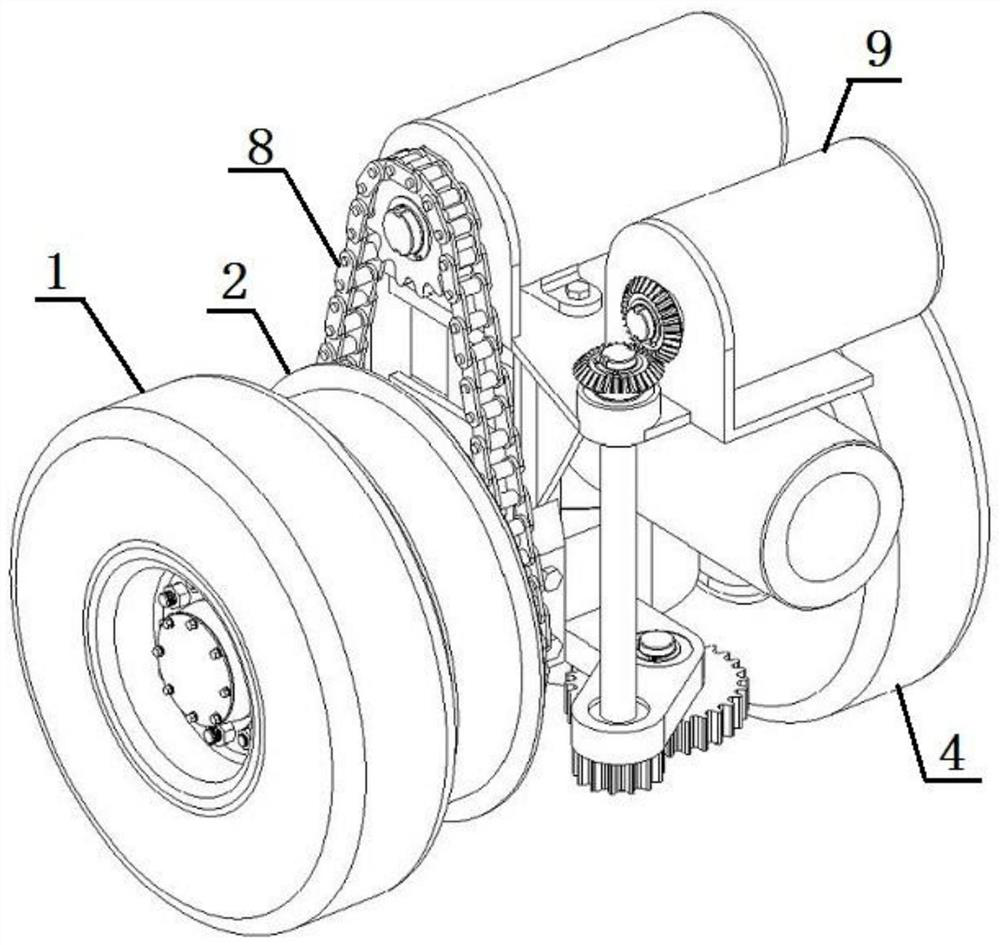

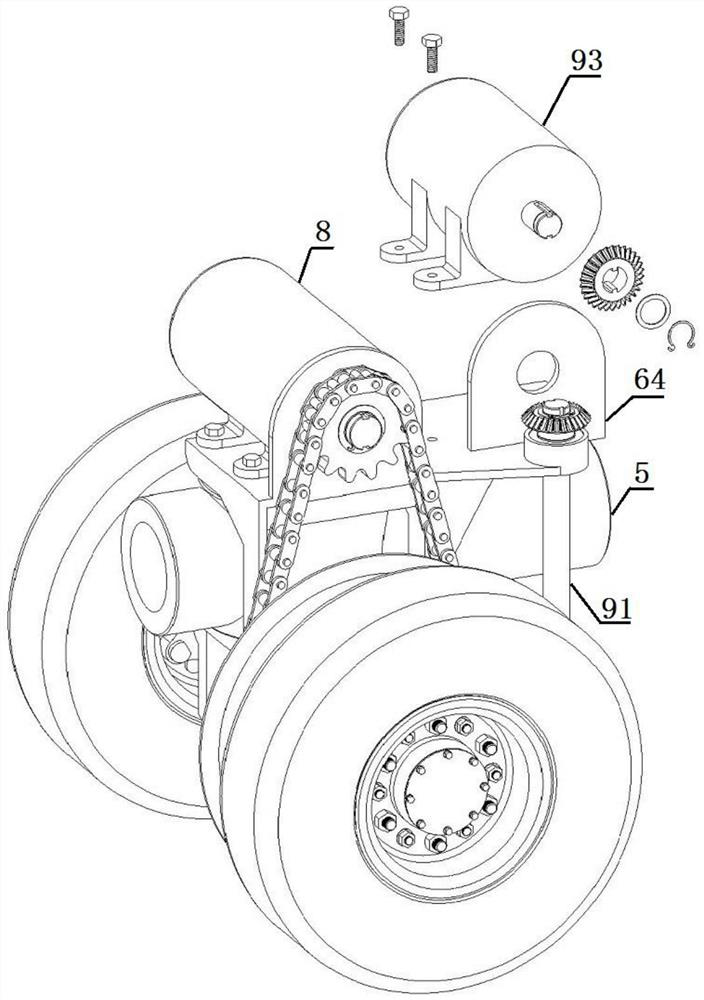

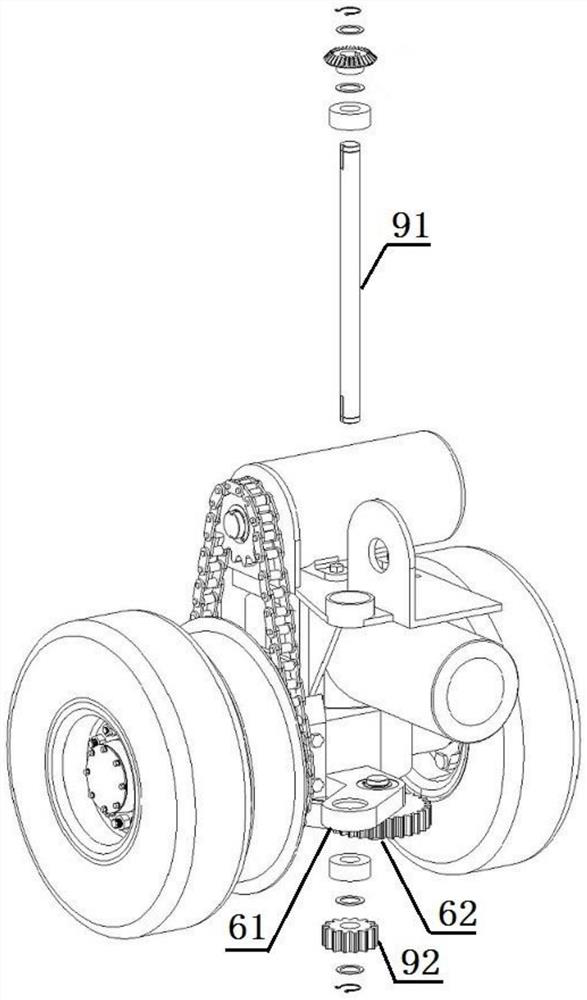

[0043] Such as Figure 1 to Figure 13 As shown, a composite wheel for construction vehicles, hereinafter referred to as composite wheel. Comprising running gear, described running gear comprises driving wheel 1, track wheel 2 and connecting seat 3, and one end of connecting seat is fixed on the track wheel, and the other end is fixed on the driving wheel, and the diameter of track wheel is less than the diameter of driving wheel.

[0044] The connecting seat protrudes outward from the side of the center seat of the rail wheel. That is, the connecting seat can be a separate component, or can be integrated with the rail wheel. Put into the connecting seat bearing 31 in the central through hole of connecting seat 3.

[0045] The running gear also includes a driven wheel 4 .

[0046] Such as Figure 14 to Figure 17 As shown, the composite wheel is used on a construction vehicle 7 . The composite wheel also includes a wheel frame 5 and an axle seat 6. The wheel frame 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com