Forming press for artificial stone manufacturing

A technology of artificial stone and press, applied in the direction of ceramic molding machines, molding conveyors, manufacturing tools, etc., can solve problems such as difficult integration, low efficiency, slow production, etc., to improve quality, improve product quality, and increase production speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

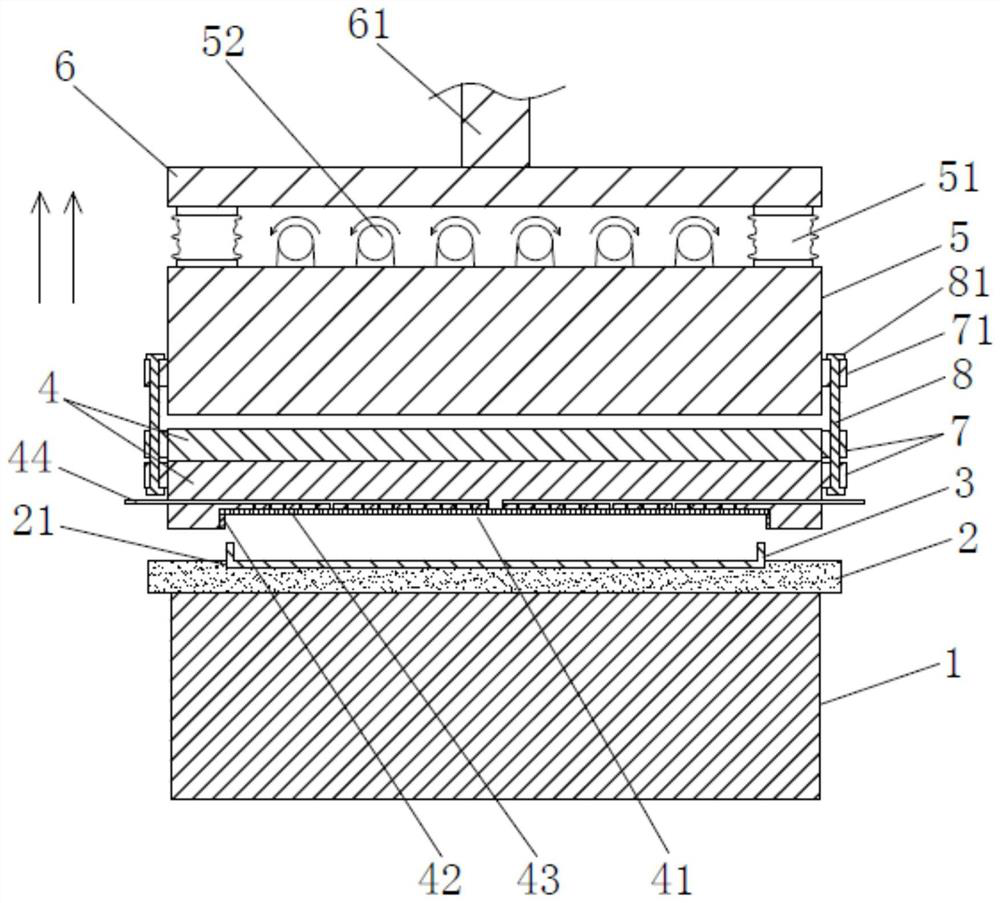

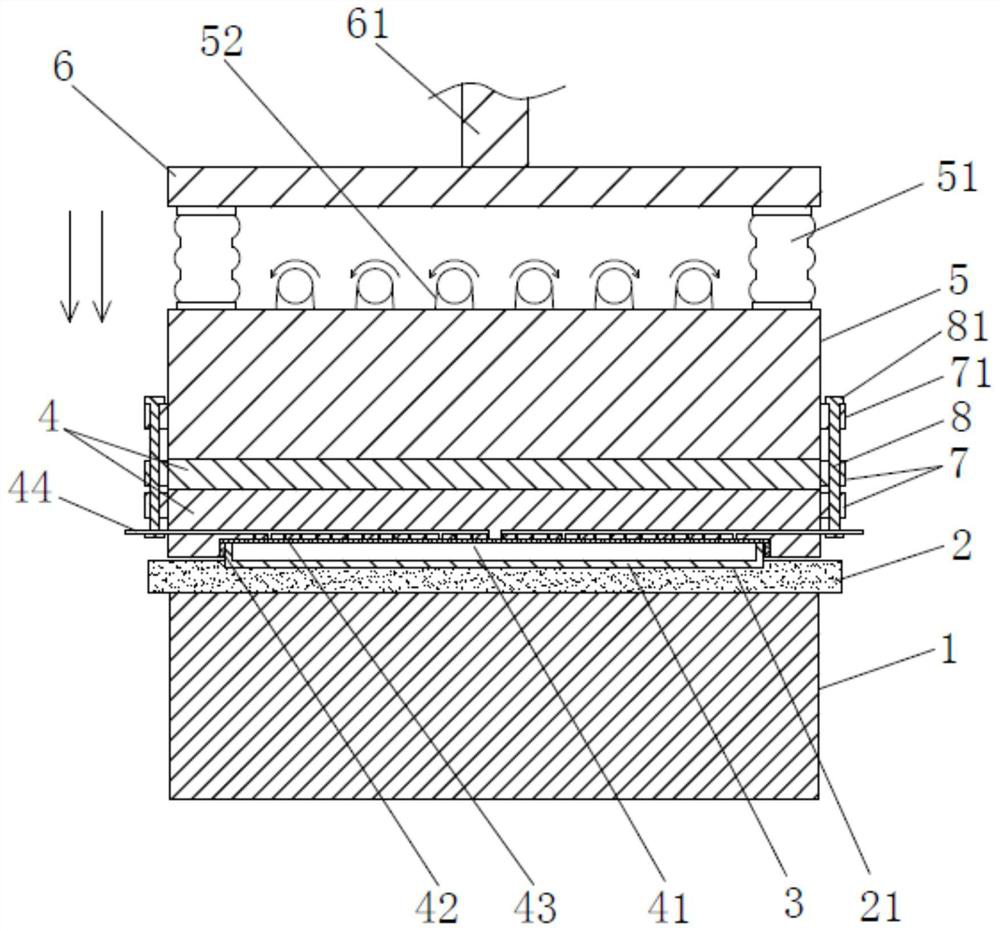

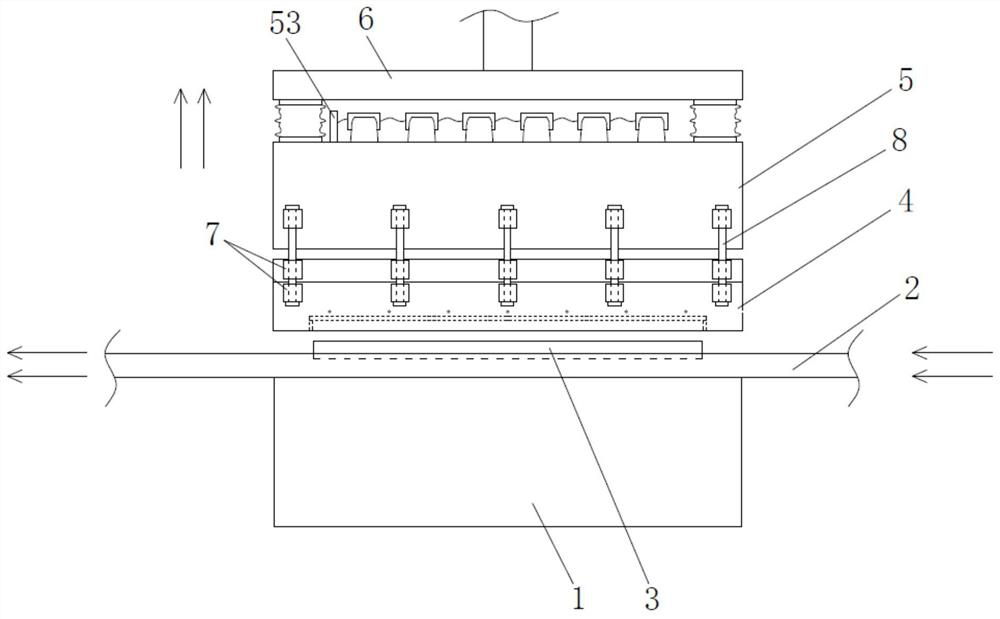

[0034] The specific embodiment of the present invention is as Figure 1-3As shown, a forming press for artificial stone manufacturing includes a pressure-bearing base 1, a horizontally movable conveyor belt 2 is provided on the upper surface of the pressure-bearing base 1, and a plurality of edge belts are detachably installed on the surface of the conveyor belt 2 The molding die frame 3 that its moving direction is set. The top of the conveyor belt 2 is horizontally provided with a guide plate 4 , an active plate 5 and a fixed mounting plate 6 in order from bottom to top. The force guiding platen 4 is suspended below the active platen 5 through a suspension mechanism, and the active platen 5 and the fixed mounting plate 6 are connected by a plurality of air springs 51 capable of vertical expansion and contraction. Two groups of vibrating motor groups with opposite directions of rotation are oppositely arranged on the upper plate surface of the active pressing plate 5 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com