Continuous ring-pull can cutting and tabletting production line

A technology for cutting and pressing sheets and cans, applied in other manufacturing equipment/tools, metal processing, metal processing equipment, etc., can solve the problems of inability to realize automatic cutting processing and automatic feeding, and improve processing production efficiency and structure. Ingenious design, the effect of reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

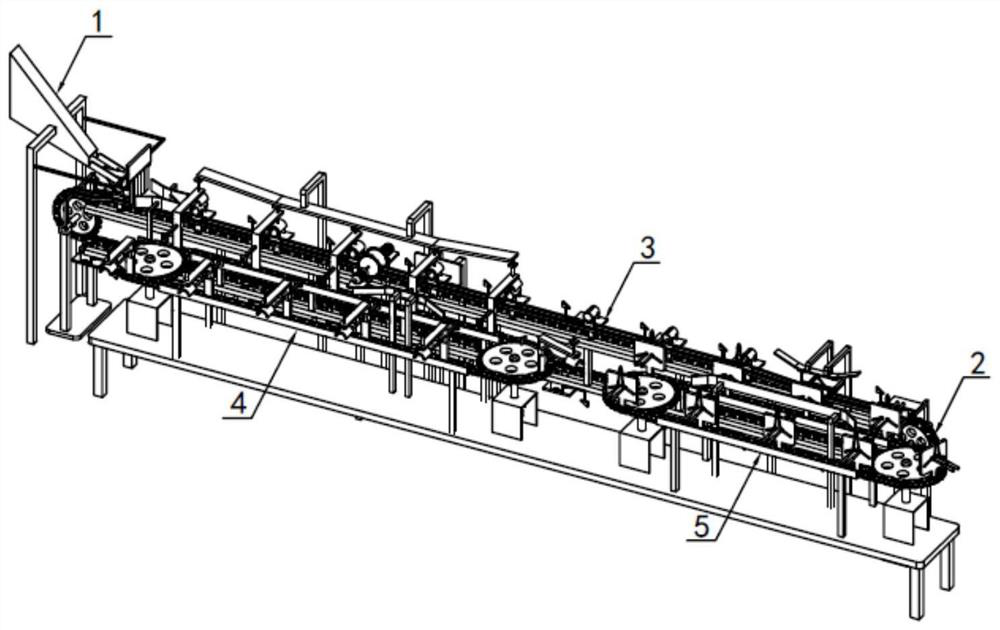

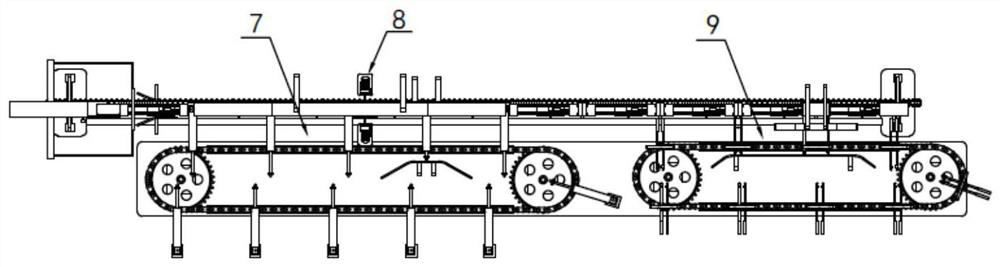

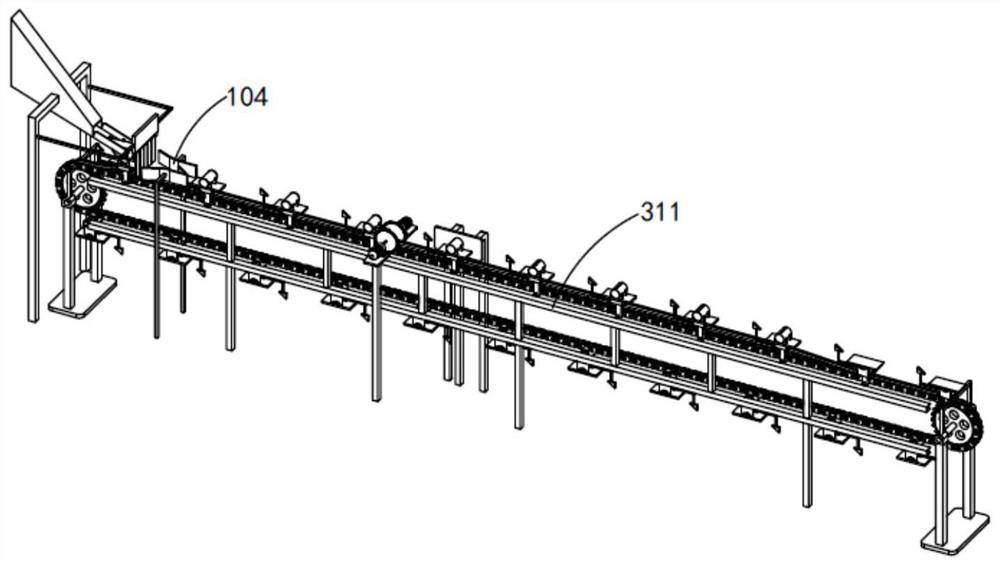

[0047] Such as Figure 1 to Figure 22 As shown, a continuous can cutting and sheeting production line includes a storage bin 1, a turning assembly 101 is provided at the bottom of the storage bin 1, a first turning device 2 is provided under the storage bin 1, and a first turning device 2 is provided under the storage bin 1. The rotating device 2 is provided with several equidistant carrying devices 3, the carrying device 3 includes a pushing assembly 301 and a supporting assembly 302, and the pushing assembly 301 is driven by the first rotating device 2 to push the The turning component 101 transfers the ready-to-be-processed cans output from the storage bin 1 to the supporting component 302 individually, and one side of the moving path of the carrying device 3 is provided with a second turning device 4 and a third turning device 5 in sequence from front to back, so that The second turning device 4 is provided with a plurality of processing devices 6, the processing device 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com