Hole milling device for machining automobile crankshaft

A crankshaft machining and hole milling technology, applied in positioning devices, metal machining equipment, metal machining mechanical parts, etc., can solve the problem of inability to move the car crankshaft to ensure the quality and accuracy of the car crankshaft milling hole, the car crankshaft is easy to move and rotate, and the milling Hole quality and precision reduction and other problems, to achieve the effect of benefiting the quality of milling holes, improving the efficiency of milling holes, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

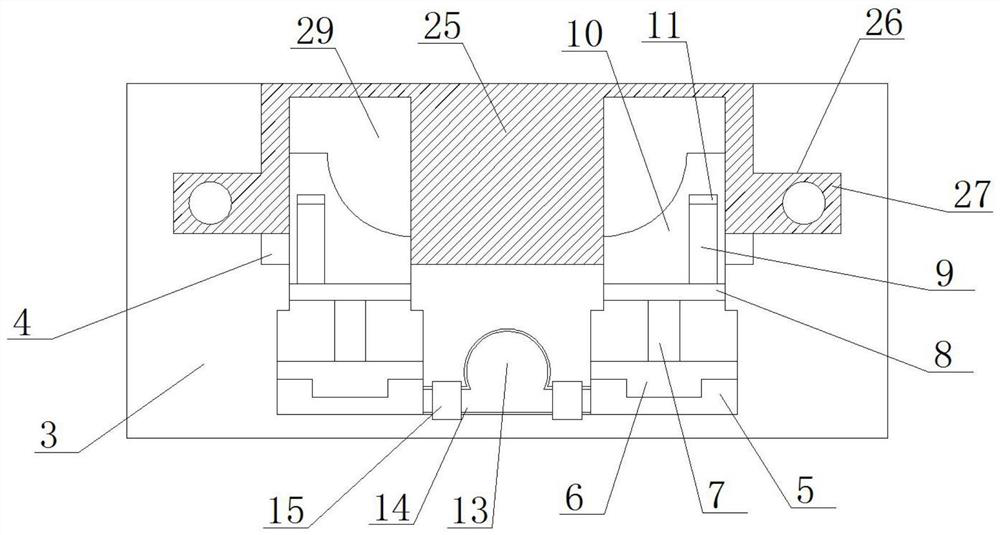

[0027] As a preferred embodiment of the present invention, the number of hexagonal limit rods 9 on the top of the top plate 8 is 2, the number of movable clamping seats 25 is 2, and the bearing seat 10 passes through the hexagonal connecting groove 11 Cooperating with the hexagonal limit rod 9 and connecting with the top plate 8, it is very convenient to disassemble the bearing seat 10 for replacement and has strong stability, will not shake during use, and ensures the quality of the milled hole.

[0028] As a preferred embodiment of the present invention, both the pressurization channel 16 and the oil supply pipeline 13 are filled with hydraulic oil.

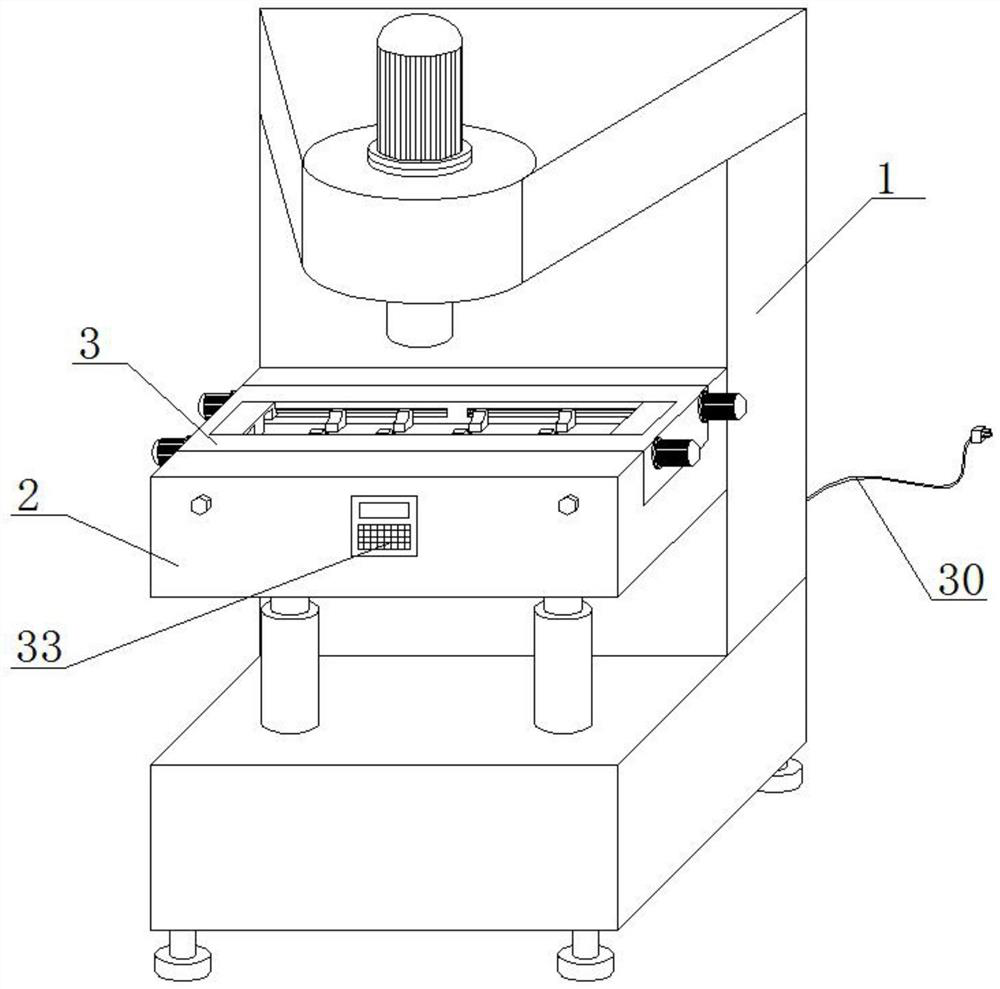

[0029] As a preferred embodiment of the present invention, the workbench 2 is fixedly installed on the milling machine 1, and the special-shaped clamping and fixing seat 3 is embedded on the workbench 2 and fixed by bolts.

[0030] As a preferred embodiment of the present invention, a control panel 33 is installed on the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com