Cheese yoghourt and preparation method thereof

A technology for yogurt and cheese, applied in the directions of milk preparations, dairy products, applications, etc., can solve the problems of cumbersome steps, time-consuming and labor-intensive, and increase product yield, etc., to increase product yield, long production time, and improve product quality. yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The preparation method of cheese yoghurt provided by the invention is specifically as follows:

[0071] 1) Raw milk standardization: standardize fresh milk and / or reconstituted milk so that the final fat content in raw milk is 2.9-3.4%, and the protein content is 2.6-3.4%;

[0072] 2) Mixing, homogenization and sterilization: circulate and mix the standardized raw milk obtained in step 1) with protein powder, cream, white sugar or salt and emulsifier at 50-55°C for 30 minutes, and hydrate for 20 minutes Finally, homogenize at a homogenization pressure of 30-40bar (secondary pressure) / 160-180bar (primary pressure); the sterilization temperature is between 90-95°C, and the sterilization time is controlled at 200-300s;

[0073] 3) Fermentation: Cool the mixed materials in step 2) to 39-43°C, inoculate the starter according to the proportion, and carry out constant temperature fermentation;

[0074] 4) Chilling: when the acidity at the end point of the fermentation is 60-7...

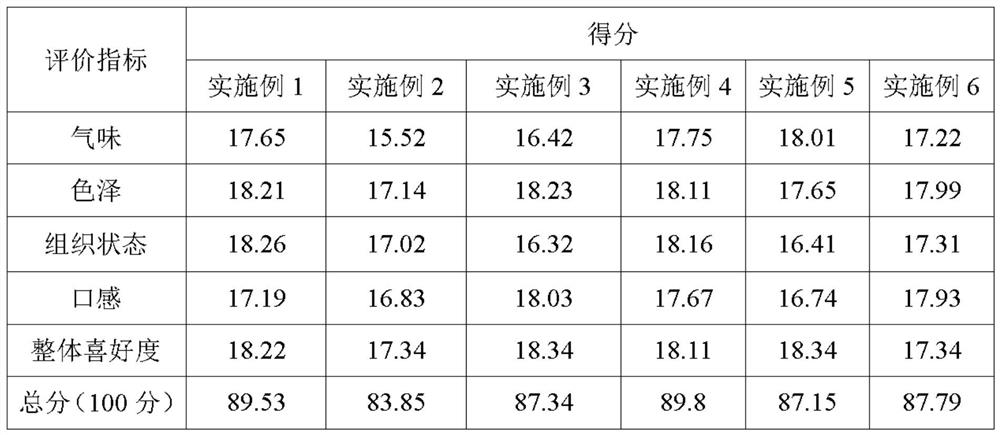

Embodiment 1

[0076] The preparation of embodiment 1 cheese yogurt

[0077] The specific production process of cheese yogurt (10kg) is as follows:

[0078] (1) Raw milk standardization: standardize fresh milk or reconstituted milk so that the final fat content in raw milk is 3.0%, and the protein content is 2.8%;

[0079] (2) Mixing, homogenization and sterilization: mix 67% of standardized raw milk obtained in step (1) with protein powder 10%, white sugar 7%, cream 16%, diacetyl tartaric acid mono-diglyceride 0.04 % Circulate and mix materials at 50°C for 30 minutes, and after hydration for 20 minutes, homogenize at a homogenization pressure of 30bar for the second stage and 160bar for the first stage; the sterilization temperature is 90°C, and the sterilization time is controlled at 200s;

[0080] (3) Fermentation: Cool the mixed materials in step (2) to 42°C, add 0.005% starter in proportion, and carry out constant temperature fermentation at 42°C for 6 hours;

[0081] Wherein, the lea...

Embodiment 2

[0084] The preparation of embodiment 2 cheese yoghurt

[0085] The specific production process of cheese yogurt (10kg) is as follows:

[0086] (1) Raw milk standardization: standardize fresh milk or reconstituted milk so that the final fat content in raw milk is 3.0%, and the protein content is 2.8%;

[0087] (2) Mixing, homogenization and sterilization: mix 66.5% of standardized raw milk obtained in step (1) with protein powder 12%, cream 21%, diacetyl tartaric acid mono-diglyceride 0.05%, salt 0.4% Circulate mixing at 50°C for 30 minutes, and after hydration for 20 minutes, perform homogenization at a secondary pressure of 30 bar and a primary pressure of 160 bar; the sterilization temperature is 90°C, and the sterilization time is controlled at 200s;

[0088] (3) Fermentation: Cool the mixed materials in step (2) to 42°C, add 0.05% starter in proportion, and carry out constant temperature fermentation at 42°C for 5.5h;

[0089] Wherein, the starter is four kinds of Lactob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com