Hardener for epoxy resins

A technology of epoxy resin and curing agent, which is applied in the direction of epoxy resin glue, epoxy resin coating, adhesive, etc., to achieve the effect of good processability, high surface quality and fast curing

Pending Publication Date: 2021-05-28

SIKA TECH AG

View PDF13 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the processability, cure speed and surface quality of the resulting epoxy coatings could be improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

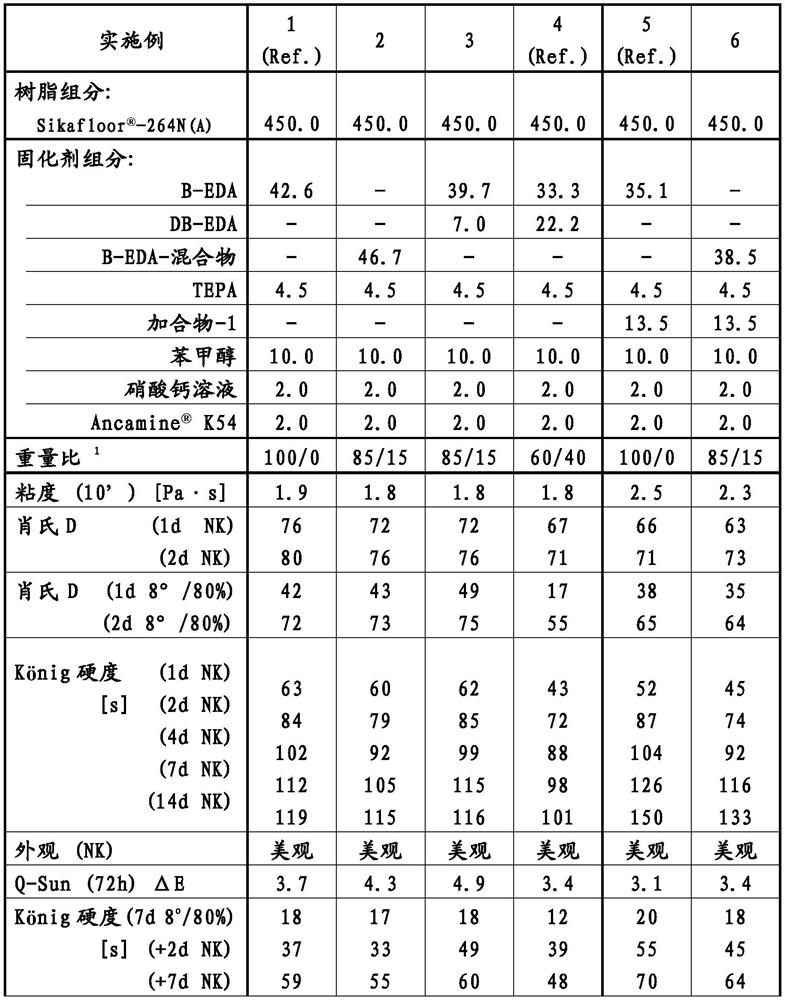

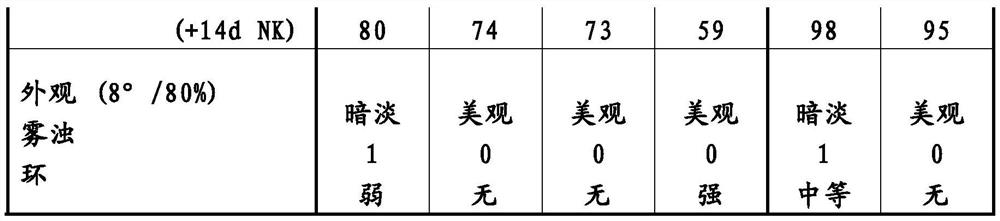

Embodiment 1 to 6

[0171] For each example, the centrifugal mixer (SpeedMixer TM DAC 150, FlackTek Inc.) was mixed with the curing agent components of the ingredients specified in Table 1 in the specified amounts (parts by weight), and stored with the exclusion of moisture.

[0172] Use the amount (parts by weight) specified in Table 1 - 264N Component A (blue) (from Sika) as resin component.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to a hardener for epoxy resins, containing N-benzyl-1,2-ethanediamine and N,N'-dibenzyl-1,2-ethanediamine in a weight ratio ranging between 65 / 35 and 95 / 5. The inventive hardener can be produced simply, thins epoxy resins particularly well, and allows the manufacture of low-emission epoxy resin products that have good workability and a long pot-life and that cure reliably and surprisingly rapidly and can be walked on after a short time, in particular even in cold conditions. Coatings of in particular high mechanical quality, with a high surface quality and a minimal tendency to yellowing, can thus be produced. Epoxy resins of this type are particularly suitable for coating floors.

Description

technical field [0001] Curing agents for epoxy resins, epoxy resin compositions and their use especially as coatings. Background technique [0002] Coatings based on epoxy resins are widely used in civil engineering. It consists of a liquid resin component and a hardener component that are mixed prior to application and then cured at ambient temperatures in the range of about 5 to 35°C to form a high strength and stable Material. Such epoxy coatings are prone to surface imperfections such as clouding, spotting, roughness, or stickiness, also known as "blushing." [0003] Haze is due to the amine contained in the curing agent component and the carbon dioxide (CO2) in the air 2 ) caused by the formation of salt, especially at high air humidity and low temperature. Especially in aesthetically demanding coating applications such as floor coverings, the appearance of haze-related surface defects is extremely detrimental and often requires laborious post-treatment or recoating...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G59/50C09D163/00

CPCC08G59/5006C08G59/5033C09D163/00C07C211/27C09J163/00

Inventor E·卡瑟米A·克拉默U·斯塔德尔曼U·布尔克哈德特

Owner SIKA TECH AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com