Brushless direct excitation motor and assembling method thereof

A technology of casing and excitation coil, which is applied to motors, electromechanical devices, electric vehicles, etc., can solve the problems of complex structure, large volume of indirect excitation motors, and difficulty in precise control of the speed of asynchronous motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

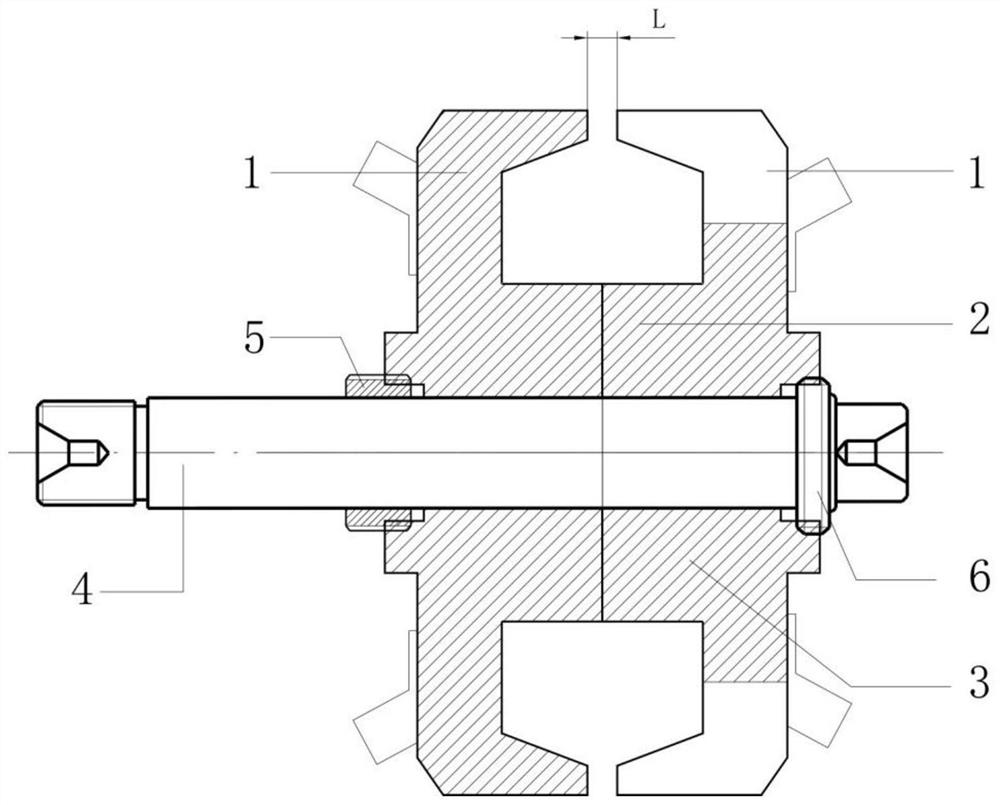

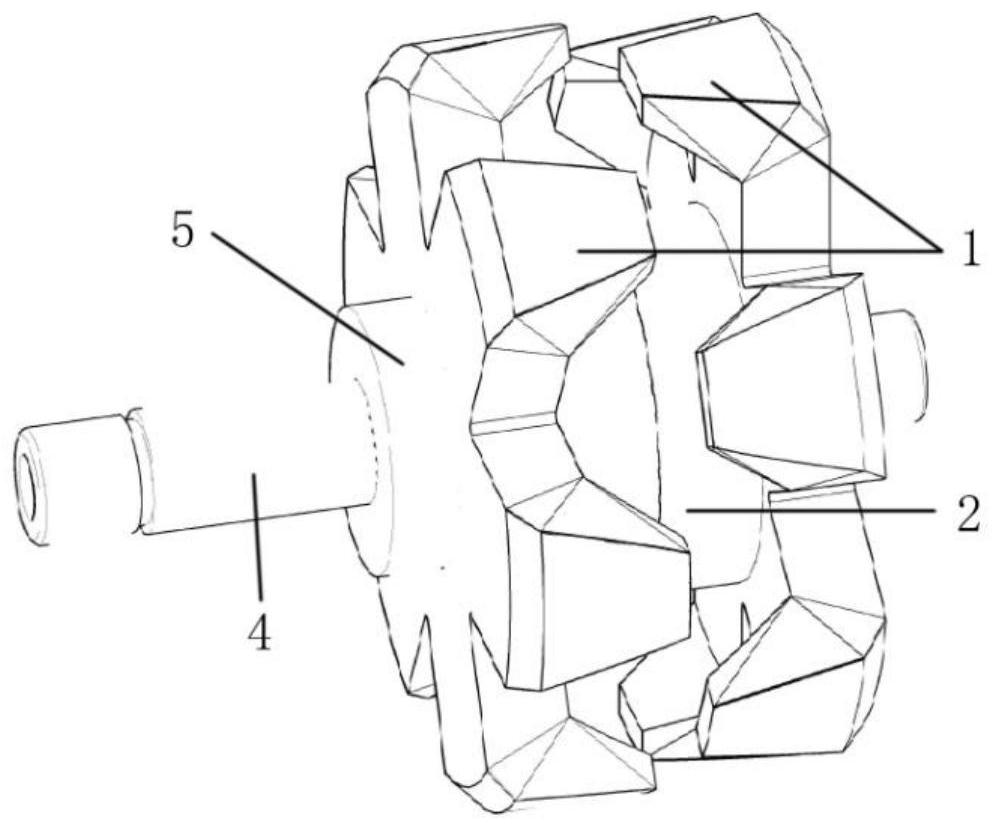

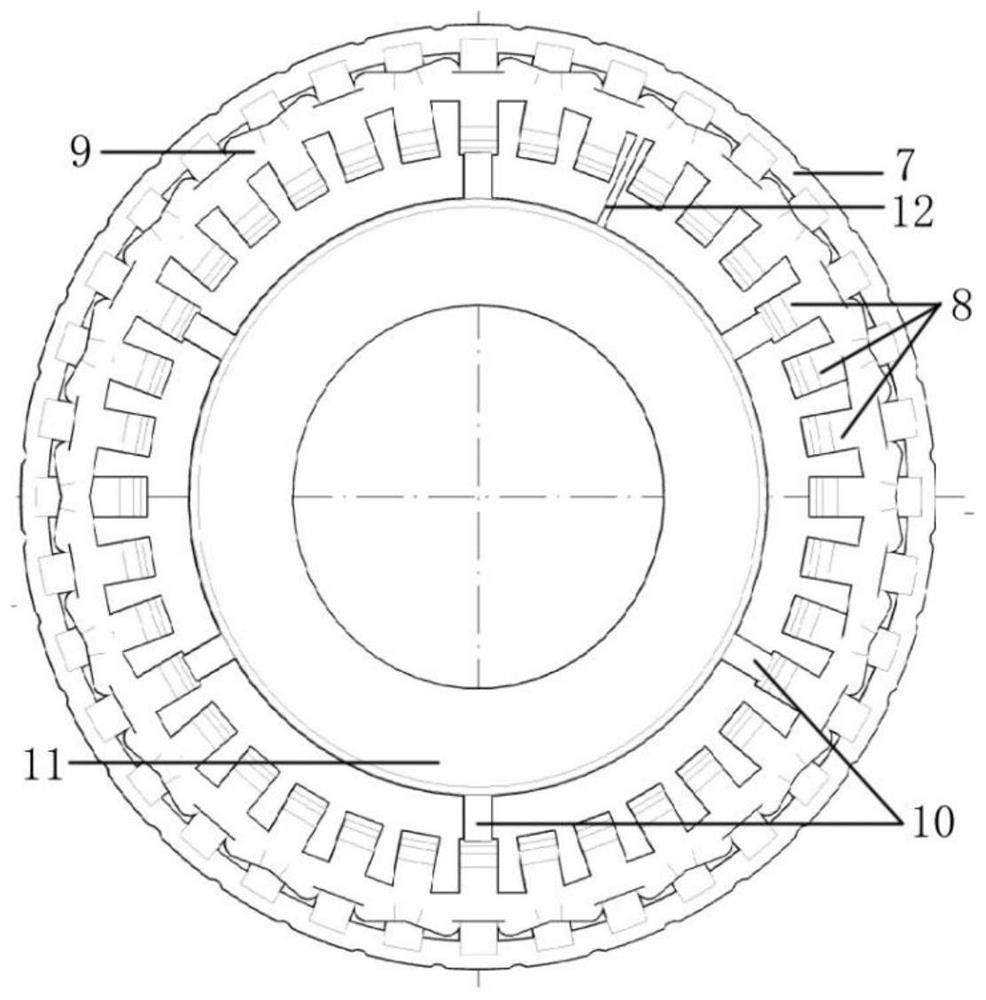

[0018] When the brushless direct excitation motor is used as an electric vehicle hub motor, the specific examples are as follows: the inner diameter of the stator is 300 mm, and three-phase distributed winding is used; the number of claw pole pairs of the rotor magnetic pole is 6 pairs, and the claw poles at both ends of the magnetic pole are staggered by 30°; The maximum excitation current is 10A; the motor adopts a fully enclosed aluminum alloy casing, and uses water cooling to absorb the heat generated by the stator winding and the excitation winding, and the temperature of the motor is controlled within 90°C. The total weight of the motor is about 38Kg, the continuous torque is 500NM, the maximum torque is 800NM, the continuous power is 50KW, the maximum speed is 12000R / min, and the durability time exceeds 30,000 hours (converted to 1.8 million kilometers), and its performance exceeds the world's advanced level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com