Polymethyl methacrylate photopolymer material as well as preparation and application thereof

A technology of polymethyl methacrylate and methyl methacrylate, which is applied in the field of holographic recording materials and can solve problems such as strong water absorption, low diffraction efficiency, and unstable gratings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

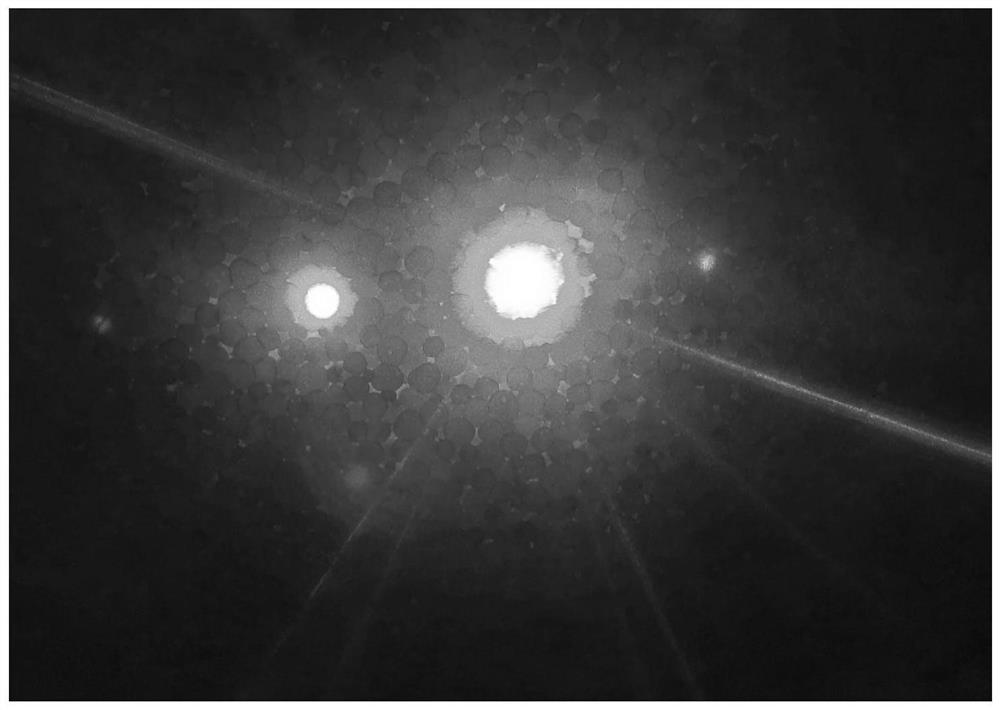

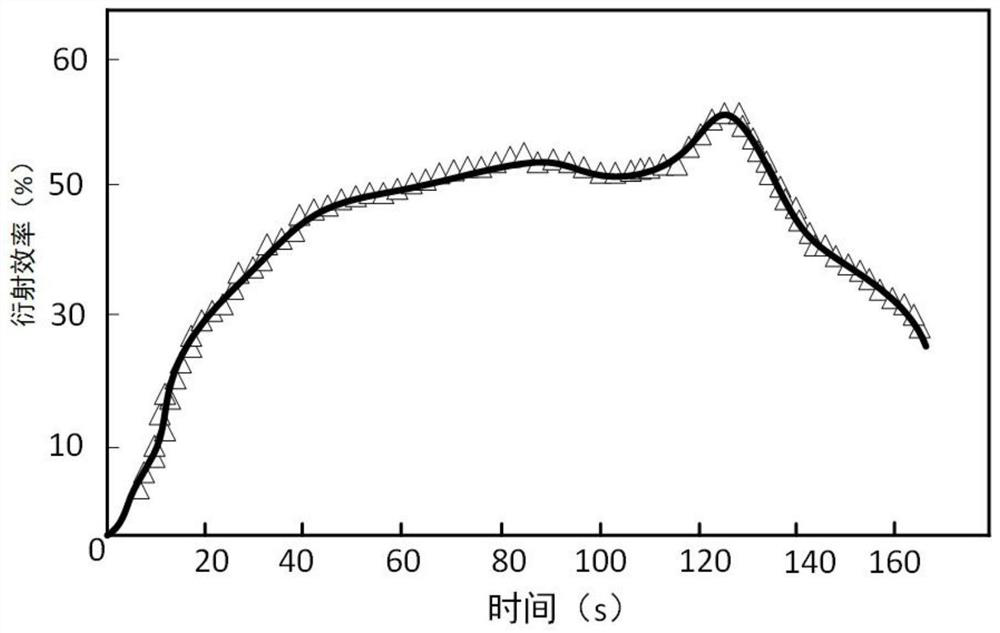

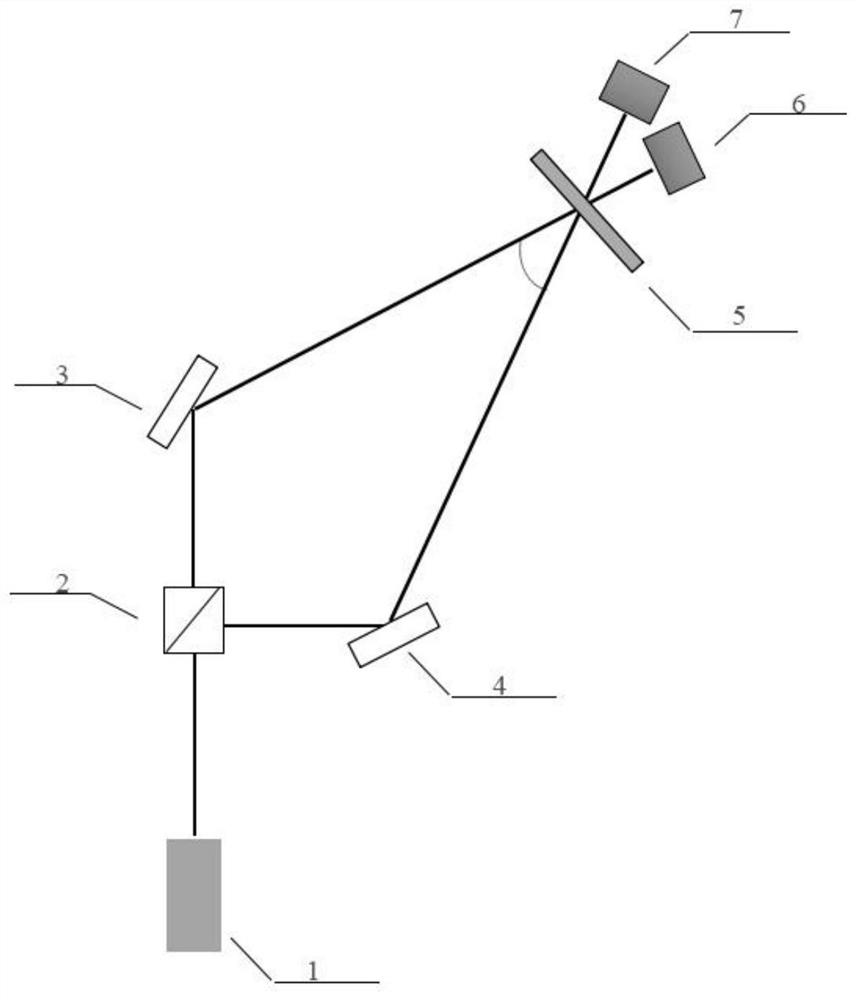

Image

Examples

Embodiment 1

[0058] The photopolymer holographic recording material is prepared by the following steps:

[0059] (1) The molds and glass substrates that need to be used in the preparation process are cleaned by ultrasonic vibration in absolute ethanol, rinsed with deionized water, put into a constant temperature oven and dried for use;

[0060] (2) Weighing methyl methacrylate (MMA) and azobisisobutyronitrile (AIBN) with a quality of 100g and 1g respectively, and mixing the two to obtain an organic mixture;

[0061] (3) The photosensitizer Irgacure 784 (TI) with a mass of 1 g was weighed, mixed with the obtained organic mixed solution, and ultrasonically oscillated in an ultrasonic cleaner for 20 minutes to mix it evenly to obtain the first mixed solution;

[0062] (4) Weigh 20nm amphiphilic SiO with a mass of 1g treated with KH570 coupling agent 2 Nanoparticles, which were added to 15g of methyl isobutyl ketone (MIBK), ultrasonic vibration for 3 hours, made a uniform SiO 2 Nanoparticle ...

Embodiment 2

[0066] The photopolymer holographic recording material is prepared by the following steps:

[0067] (1) The molds and glass substrates that need to be used in the preparation process are cleaned by ultrasonic vibration in absolute ethanol, rinsed with deionized water, put into a constant temperature oven and dried for use;

[0068] (2) Weighing methyl methacrylate (MMA) and azobisisobutyronitrile (AIBN) with a quality of 100g and 1g respectively, and mixing the two to obtain an organic mixture;

[0069] (3) The photosensitizer Irgacure 784 (TI) with a mass of 2 g was weighed, mixed with the obtained organic mixed solution, and ultrasonically oscillated in an ultrasonic cleaner for 20 minutes to mix it evenly to obtain the first mixed solution;

[0070] (4) Weigh 20nm amphiphilic SiO with a mass of 1g treated with KH570 coupling agent 2 Nanoparticles, which were added to 15g of methyl isobutyl ketone (MIBK), ultrasonic vibration for 3 hours, made a uniform SiO 2 Nanoparticle ...

Embodiment 3

[0074] The photopolymer holographic recording material is prepared by the following steps:

[0075] (1) The molds and glass substrates that need to be used in the preparation process are cleaned by ultrasonic vibration in absolute ethanol, rinsed with deionized water, put into a constant temperature oven and dried for use;

[0076] (2) Weighing methyl methacrylate (MMA) and azobisisobutyronitrile (AIBN) with a quality of 100g and 1g respectively, and mixing the two to obtain an organic mixture;

[0077] (3) The photosensitizer Irgacure 784 (TI) with a mass of 3 g was weighed, mixed with the obtained organic mixed solution, and ultrasonically oscillated in an ultrasonic cleaner for 20 minutes to mix it evenly to obtain the first mixed solution;

[0078] (4) Weigh 1g of 20nm amphiphilic SiO2 nanoparticles treated with KH570 coupling agent, add it to 15g of methyl isobutyl ketone (MIBK), and ultrasonically vibrate for 3 hours to obtain a uniform SiO2 2 Nanoparticle dispersion; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com