A multi-sensing signal fusion monitoring method and system for dimensionality reduction of milling data of thin-walled parts

A signal fusion and data dimensionality reduction technology, applied in computer parts, machine learning, instruments, etc., can solve data complexity, high data compression rate, inefficient multi-sensor signal fusion strategy, and large computational load in the training process, etc. problem, to achieve the effect of improving sensitivity, reducing the number of training samples, and reducing data complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

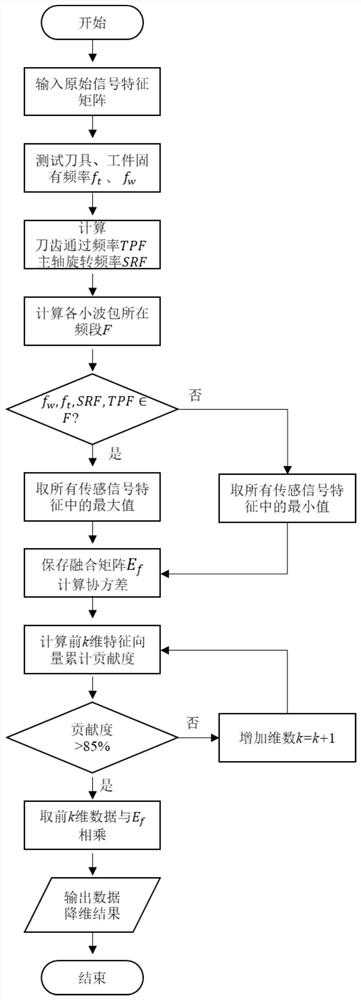

[0043] This embodiment provides a multi-sensor signal fusion monitoring method for dimensionality reduction of thin-walled milling data, such as figure 1 shown, including:

[0044] Obtain the original signal feature matrix composed of multi-sensor signal wavelet packet energy;

[0045] Calculate the natural frequency of the workpiece and tool according to the frequency response function, calculate the spindle rotation frequency and cutter tooth passing frequency under the corresponding milling parameters, and calculate the frequency band where all wavelet packets are located;

[0046] Determine whether the wavelet packet frequency band includes the natural frequency of the workpiece, the tool natural frequency, the spindle rotation frequency and the tooth passing frequency, and take values for different wavelet packet frequency bands to obtain the eigenvector of the fusion multi-sensor signal;

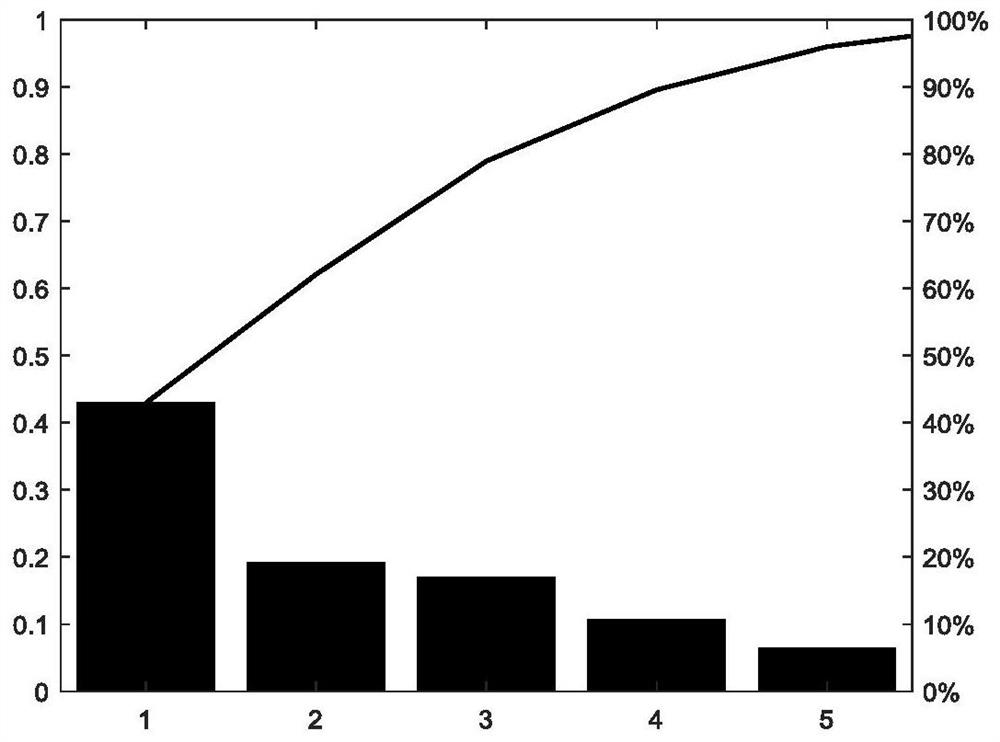

[0047] According to the eigenvector of the fusion multi-sensor signal, the orig...

Embodiment 2

[0079] This embodiment provides a multi-sensor signal fusion monitoring method for dimensionality reduction of milling data of thin-walled parts, including the following steps:

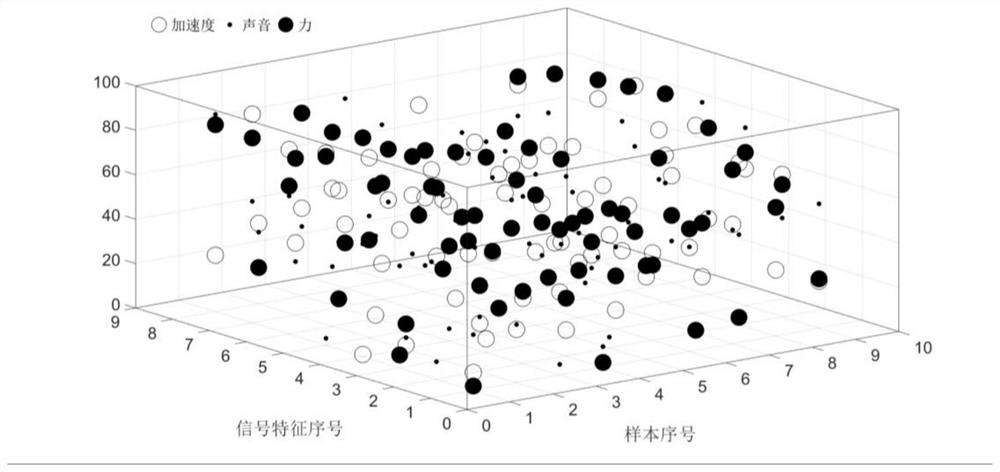

[0080] S1. Input the original signal characteristic matrix composed of wavelet packet energy of each sensing signal (acceleration signal, sound signal, milling force signal in this embodiment). There are 9 groups of experimental samples in the original data set, and each group of experiments collects three kinds of signals: acceleration, sound, and milling force, and each signal is decomposed by three layers of wavelet packets, thus 2 3 wavelet packet energy, that is, the original data set has a total of 27*8 signal features, and the scatter distribution of the original data set is as follows figure 2 shown.

[0081] S2. It is easy to obtain the frequency response function and natural frequency of the workpiece and the cutting tool according to the existing public technology. In this embodiment, the...

Embodiment 3

[0103] This embodiment provides a multi-sensor signal fusion monitoring data dimensionality reduction system for thin-walled parts milling, including:

[0104] The original signal feature matrix acquisition module is configured to: acquire an original signal feature matrix composed of multi-sensor signal wavelet packet energy;

[0105] The data calculation module is configured to: calculate the natural frequency of the workpiece and the tool according to the frequency response function, calculate the spindle rotation frequency and the cutter tooth passing frequency under the corresponding milling parameters, and calculate the frequency band where all wavelet packets are located;

[0106] The fusion eigenvector acquisition module is configured to: judge whether the frequency band of the wavelet packet contains the natural frequency of the workpiece, the natural frequency of the tool, the rotation frequency of the spindle and the passing frequency of the cutter tooth, and take va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com