Deep learning coalbed methane screw pump well health index prediction method and system

A technology of health index and deep learning, applied in electrical digital data processing, instruments, design optimization/simulation, etc., can solve problems such as lack of testing equipment, high failure rate, untimely management, etc., and achieve real-time quantitative evaluation and high prediction The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

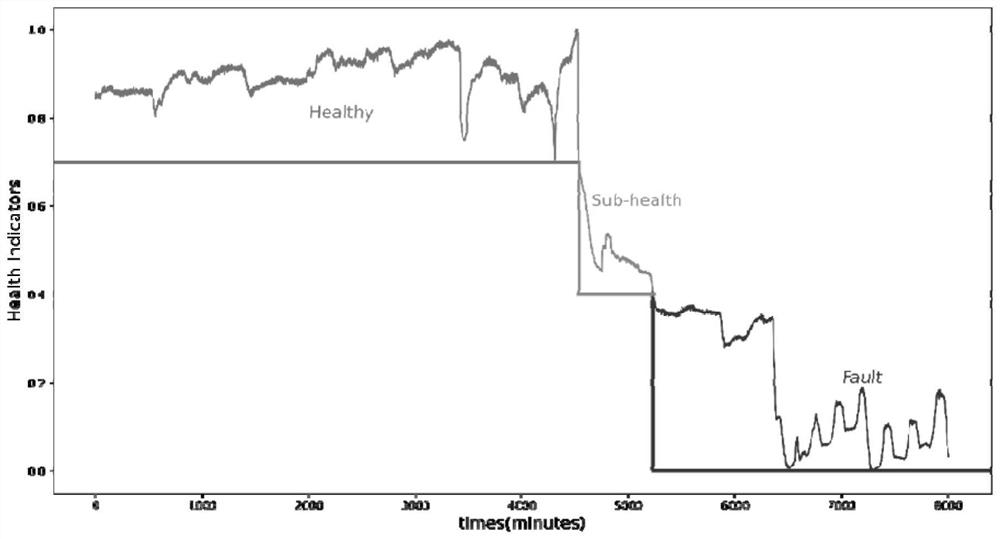

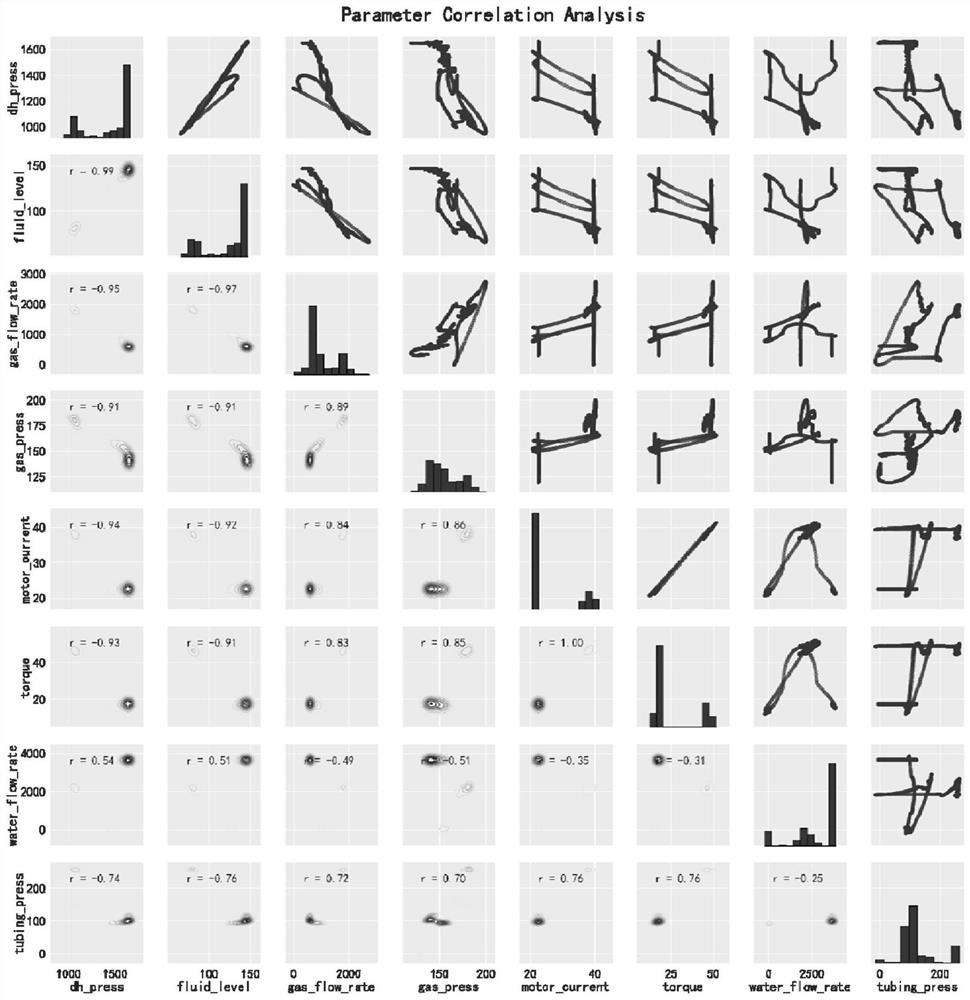

[0111] In this example, the real-time dynamic production data of 30 PCP fault wells and 6 normal operating wells in a coalbed methane block in the SURAT Basin of Australia were collected from June 2017 to January 2020, including bottomhole flow pressure, dynamic fluid Surface, gas production, water production, current, voltage, torque, oil pressure, casing pressure, speed and voltage, etc. 10 parameters, the data collection density is 1min. The fault types of the collected faulty wells include six types of faults: pump dry grinding, oil pipe blockage, stator blockage, oil pipe breakage, joint breakage, and pump efficiency reduction. The following mainly takes Well E001 as an example to analyze the production characteristics, calculate the health index, and diagnose and warn the faults.

[0112] 1> Analyze the production characteristics of CBM screw pump wells, and select at least one main control parameter suitable for the wells in the entire block.

[0113] In the data prepr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com