Mortise and tenon joint structure for gate

A mortise-and-mortise and gate technology, which is used in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of weak connection strength and difficult installation, and achieve the effects of large force strength, increased joint area and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

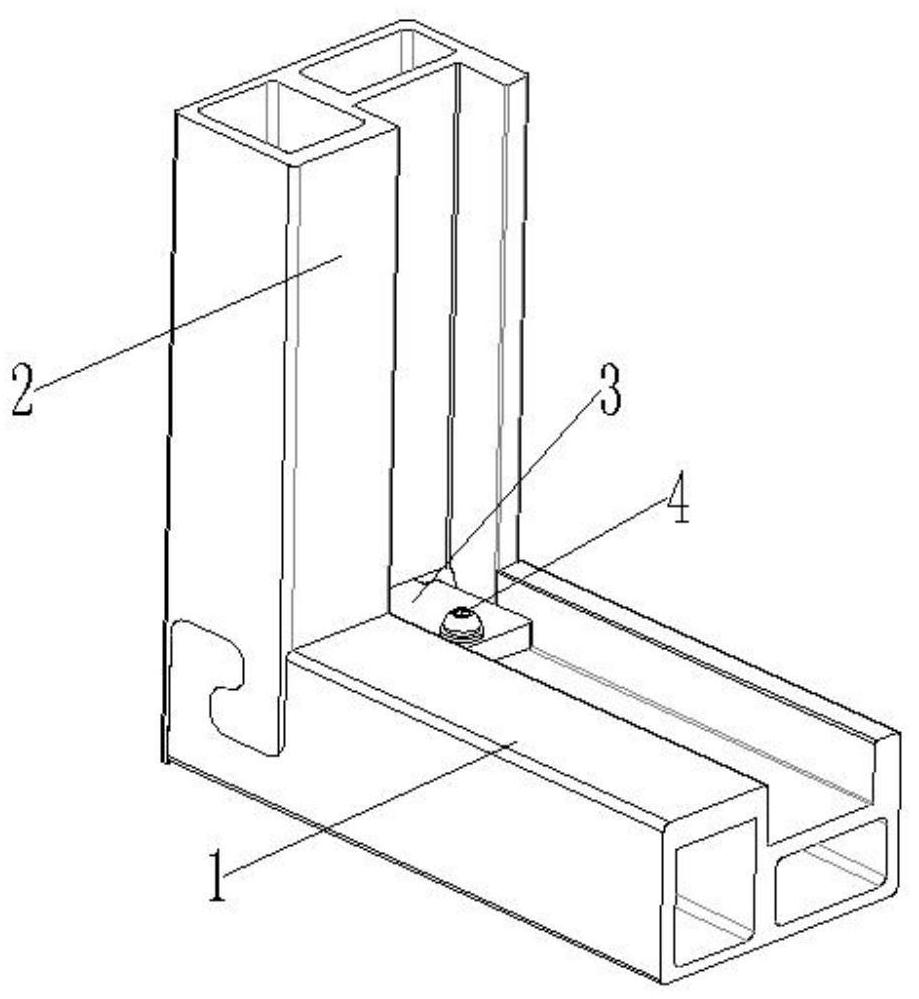

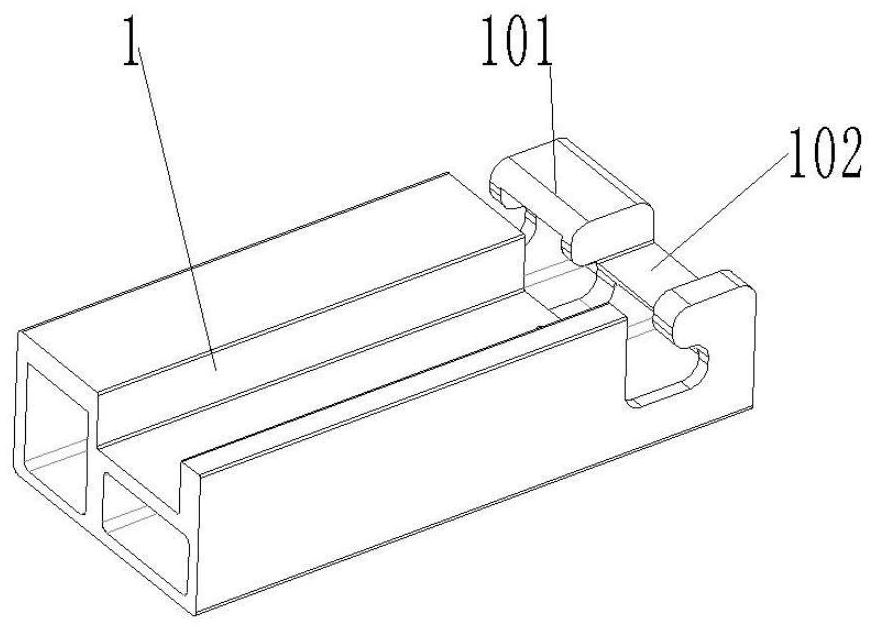

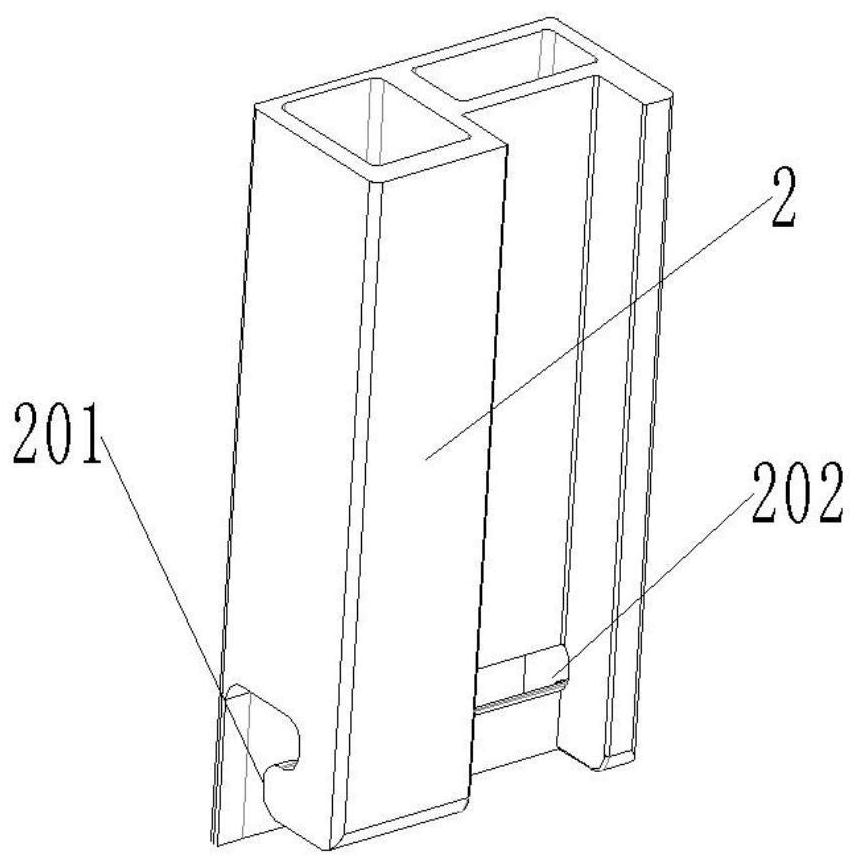

[0023] Such as figure 1 As shown, a mortise and tenon structure for a gate, including a horizontal profile 1, a vertical profile 2 and a stabilizer 3, the end of the horizontal profile 1 is provided with a first hook-shaped protrusion 101, and the end of the vertical profile 2 A second hook-shaped protrusion 201 is provided. The first hook-shaped protrusion 101 and the second hook-shaped protrusion hook 201 are connected together to form an insertion groove 102. After the stabilizer 3 is inserted into the insertion groove 102, it is fastened by a column The part 4 is fixed to realize the connection of the horizontal profile 1 and the vertical profile 2.

[0024] In this embodiment, the horizontal profile 1 and the vertical profile 2 are entangled with each other, and locked and fixed by the stabilizer 3 and the column fastener 4, thereby achieving a firm connection effect and convenient installation characteristics of the steel structure.

[0025] Specifically, refer to fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com