Liquid-driven ultrahigh-pressure compressed air energy storage system and method

A compressed air energy storage and ultra-high pressure technology, applied in the field of energy storage, can solve the problems of large volume, high cost and low energy storage density of artificially built pressure vessels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

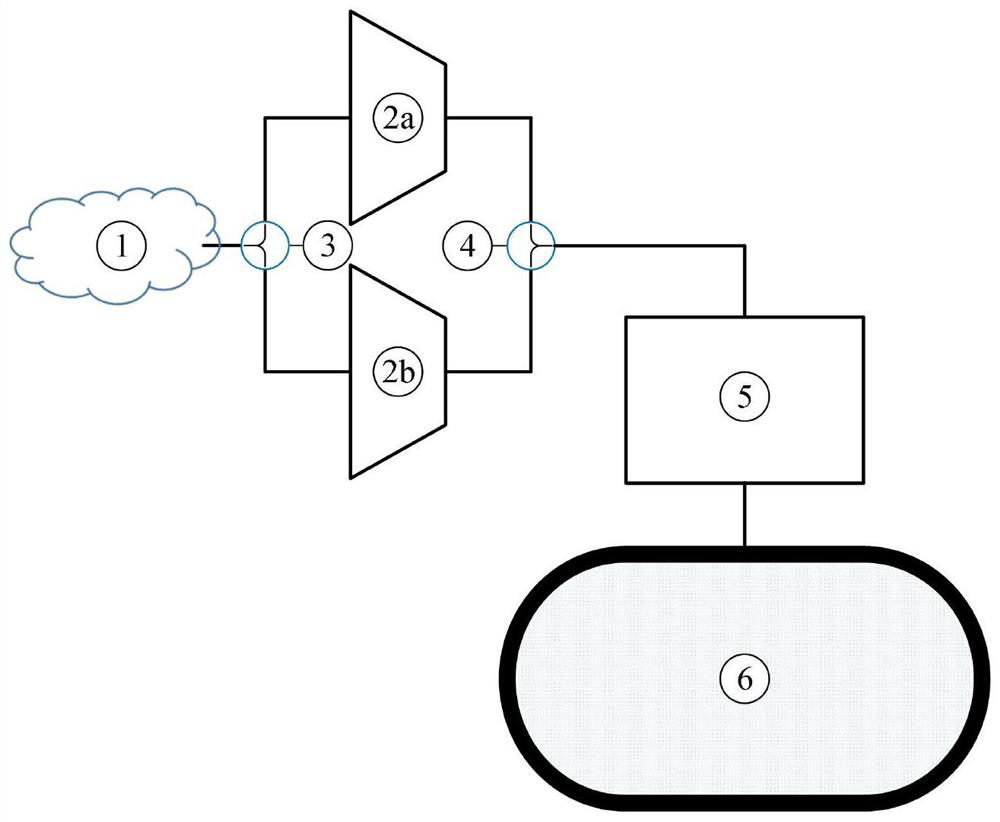

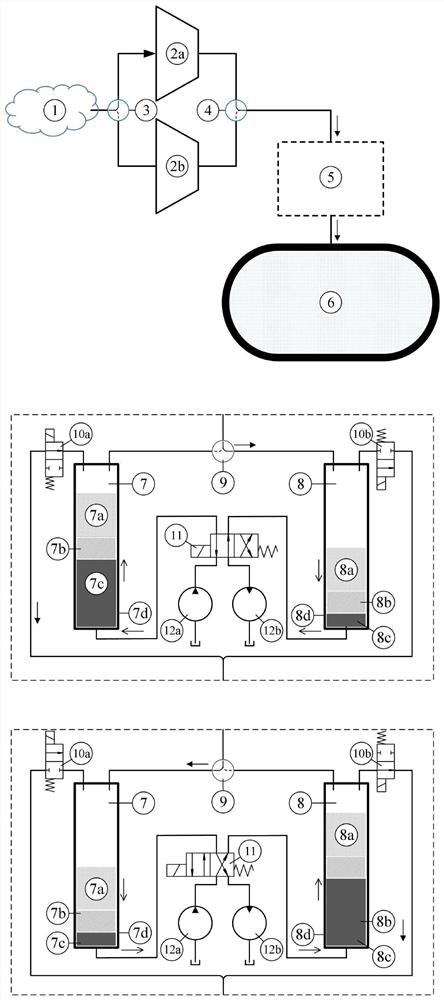

[0025] The embodiment of the invention discloses a liquid-driven ultra-high pressure compressed air energy storage system, which consists of a low-pressure air compressor (2a), a low-pressure expander (2b), a liquid piston high-pressure subsystem (5) and a high-pressure gas storage tank (6) composition. Including the following processes: low-pressure compression process, gas-liquid pressurization process, gas-liquid expansion process and low-pressure expansion process;

[0026] When storing energy, the air enters the high-pressure air storage tank (6) after the energy is stored through the low-pressure compression process and the gas-liquid pressurization process;

[0027] The low-pressure compression process: the atmosphere (1) is sucked into the low-pressure compressor (2a), and the air is compressed to obtain low-pressure air to be discharged;

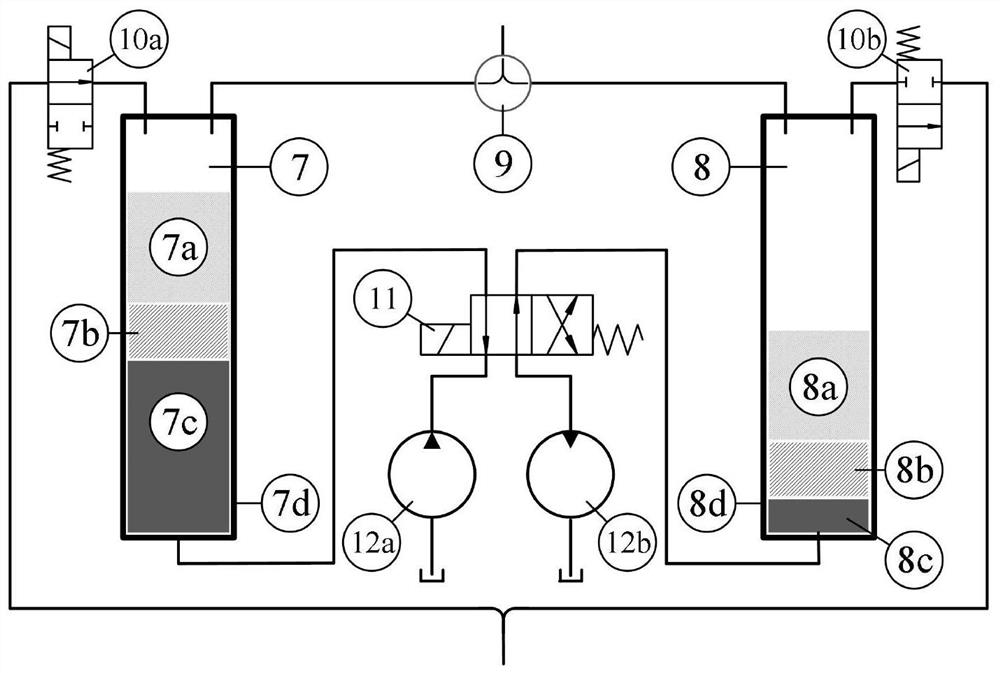

[0028] The gas-liquid pressurization process: low-pressure air is charged into the cylinder body (8d) through the pilot valve (9)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com