Outdoor anti-skid elastic floor and manufacturing method

A kind of elastic floor and floor technology, which is applied in the direction of architecture, building structure, floor, etc., can solve the problems that the floor does not have a protective effect, affects the use effect of the floor, and reduces the life of the floor, and achieves performance improvement, strong mechanical strength, Strong anti-stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

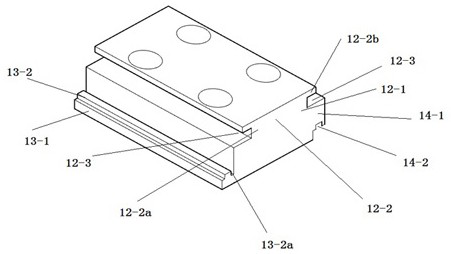

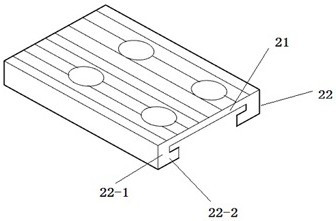

[0043] refer to Figure 1 to Figure 4 , shows an outdoor non-slip resilient floor, which is assembled from a plurality of floor units, and the floor unit includes a base material 1 and a protective plate 2 attached to the base material 1 .

[0044] Such as figure 1 and figure 2 The substrate 1 shown includes a base layer 11 , a protruding limiting clip 12 on the upper surface of the base layer 11 , a limiting insert 13 on one side of the base layer 11 , and a limiting fitting 14 on the other side of the base layer 11 . The base layer 11 shown is a square plate. Such as figure 1 and figure 2 The shown limit clip 12 includes a connecting portion 12-1 and a main body portion 12-2, and the shown main body portion 12-2 includes a vertically arranged support plate 12-2a and a limit plate 12 located on the upper part of the support plate 12-2a - 2b, the two sides of the supporting plate 12-2a shown cooperate with the ground of the limiting plate 12-2b and the upper surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com